Metal Fabrication

Sheet Metal Fabrication in the USA

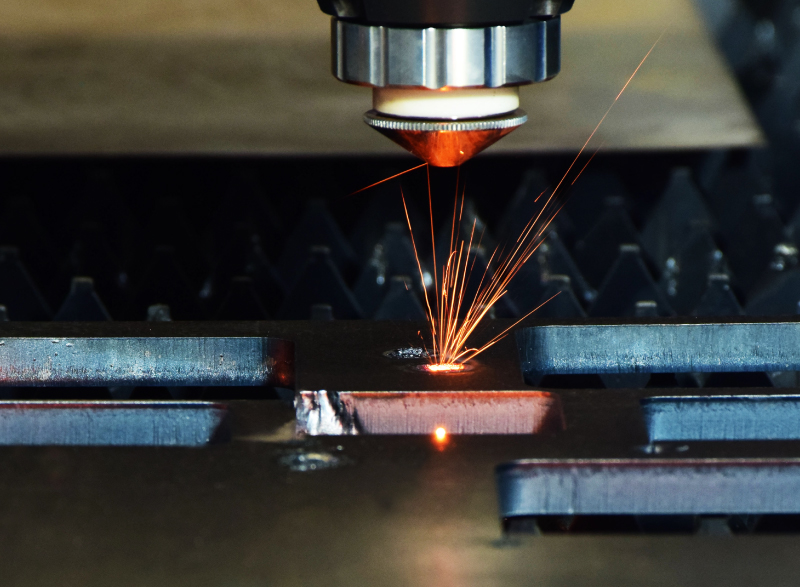

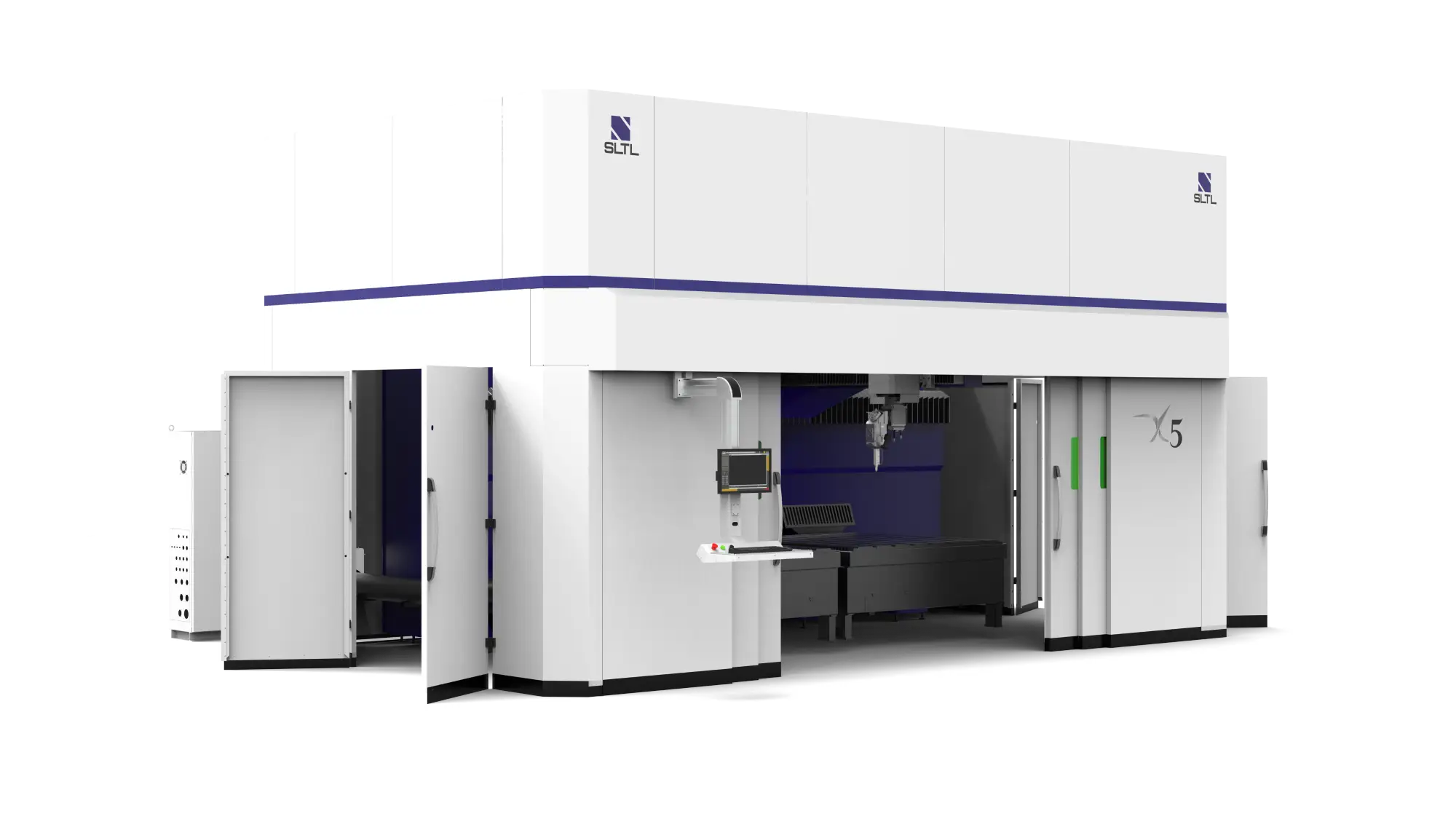

Sheet metal fabrication in the USA is essential to industries such as automotive, aerospace, construction, HVAC, and heavy machinery. It involves transforming flat metal sheets into precision-engineered parts and assemblies through processes like laser cutting, bending, welding, and finishing.

Modern American fabrication shops increasingly rely on fiber laser cutting systems to achieve clean, accurate cuts, faster cycle times, and reduced material waste. These technologies enable manufacturers to handle diverse materials, from stainless steel and aluminum to brass and copper, with exceptional precision.

At SLTL Group, we provide U.S. manufacturers with advanced laser cutting machines designed to optimize productivity, enhance part quality, and streamline every stage of fabrication. Whether you’re producing enclosures, industrial panels, or custom metal components, SLTL’s solutions empower your U.S. manufacturing operations with smart automation, high-speed performance, and long-term reliability.

Automotive Industry

The U.S. automotive industry is evolving rapidly, demanding advanced manufacturing technologies that ensure precision, speed, and efficiency. SLTL Group provides cutting-edge 3D laser cutting machines and robotic laser solutions designed to meet the needs of American automakers and suppliers. These systems deliver superior accuracy, faster production cycles, and reduced material waste—ideal for fabricating body panels, frames, and structural components. With IoT-enabled smart manufacturing and Industry 4.0 integration, SLTL empowers U.S. manufacturers to achieve next-level automation and consistent quality. Trusted globally, SLTL’s laser technologies drive innovation, productivity, and sustainability across the automotive manufacturing sector in the USA.

Agriculture Industry

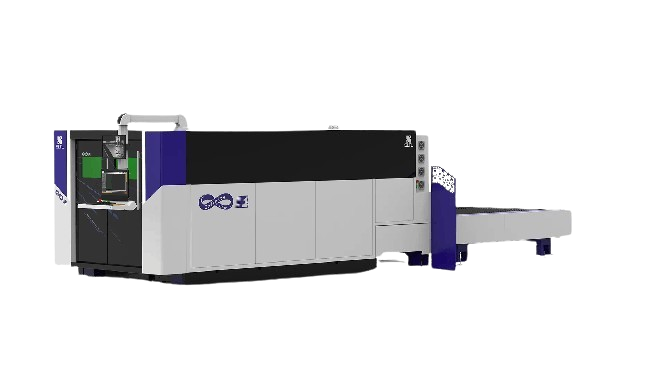

Elevate Your Agricultural Production with SLTL’s 2D Cutting Series

In the agriculture sector, precision, productivity and efficiency are essential for producing reliable equipment like rotavator side plates, Digger Rake, Cultivator, Thresher and many more. SLTL’s 2D laser cutting machine provides the perfect solution, delivering high-precision laser cutting that improves both performance and productivity.

Traditional cutting methods often fall short, causing material wastage and inefficiencies. SLTL’s advanced 2D laser cutting machine offers clean, precise cuts with minimal heat-affected zones, ensuring that your agricultural components are durable and perform at their best. Whether working with stainless steel, aluminum, or mild steel, SLTL’s machines handle various materials with ease, eliminating the need for costly secondary processes.

Equipped with smart features, SLTL’s 2D metal laser cutting machine streamlines production, reduces operational costs, and cuts down on material waste. With high-speed cutting and consistent quality, they help manufacturers achieve more while minimizing environmental impact.

For agricultural manufacturers looking to boost precision, efficiency, and productivity, SLTL’s 2D cutting series is the key to a more productive and cost-effective future.

Furniture Industry

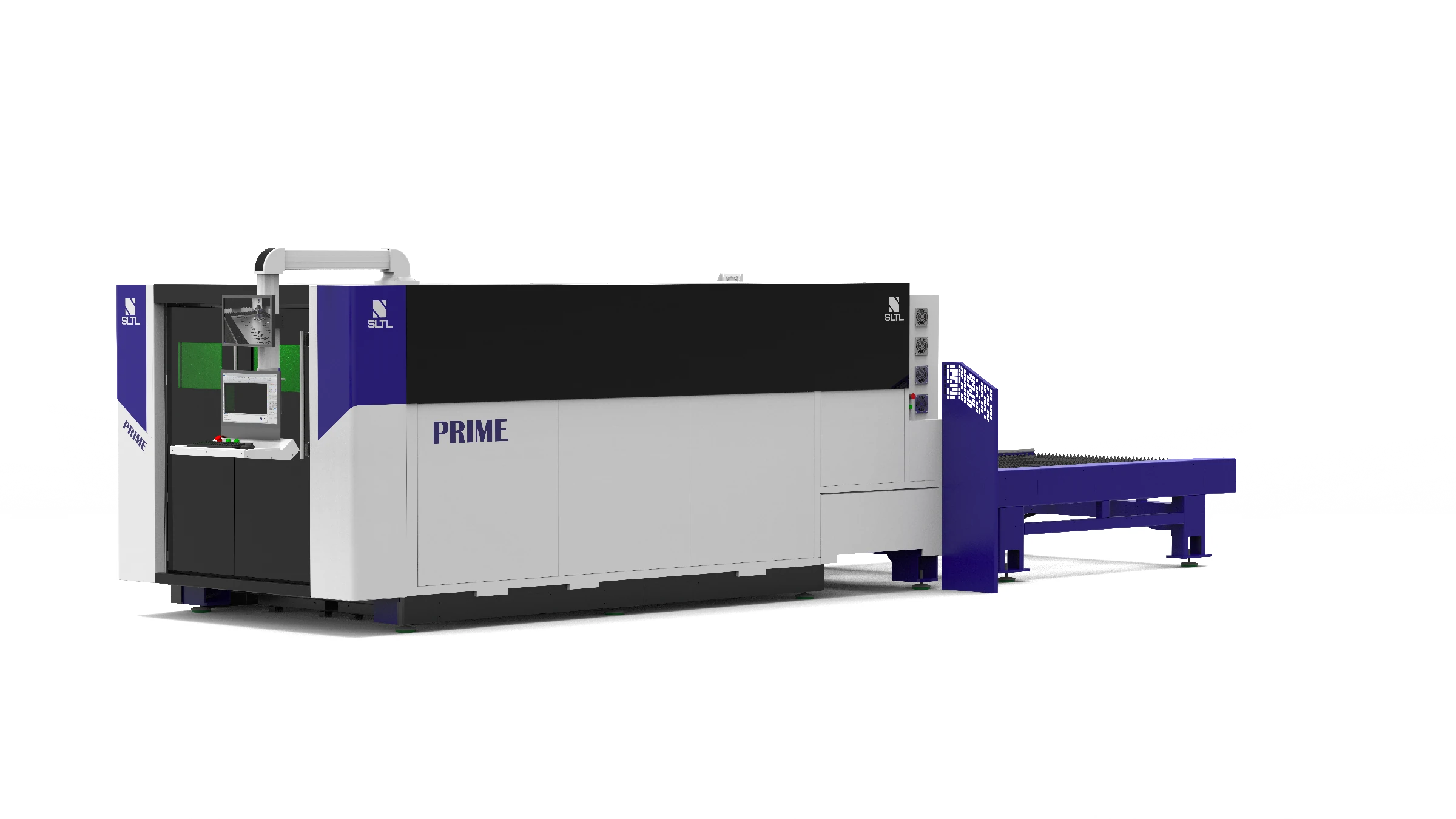

SLTL Laser Cutting Solutions for the Furniture Industry

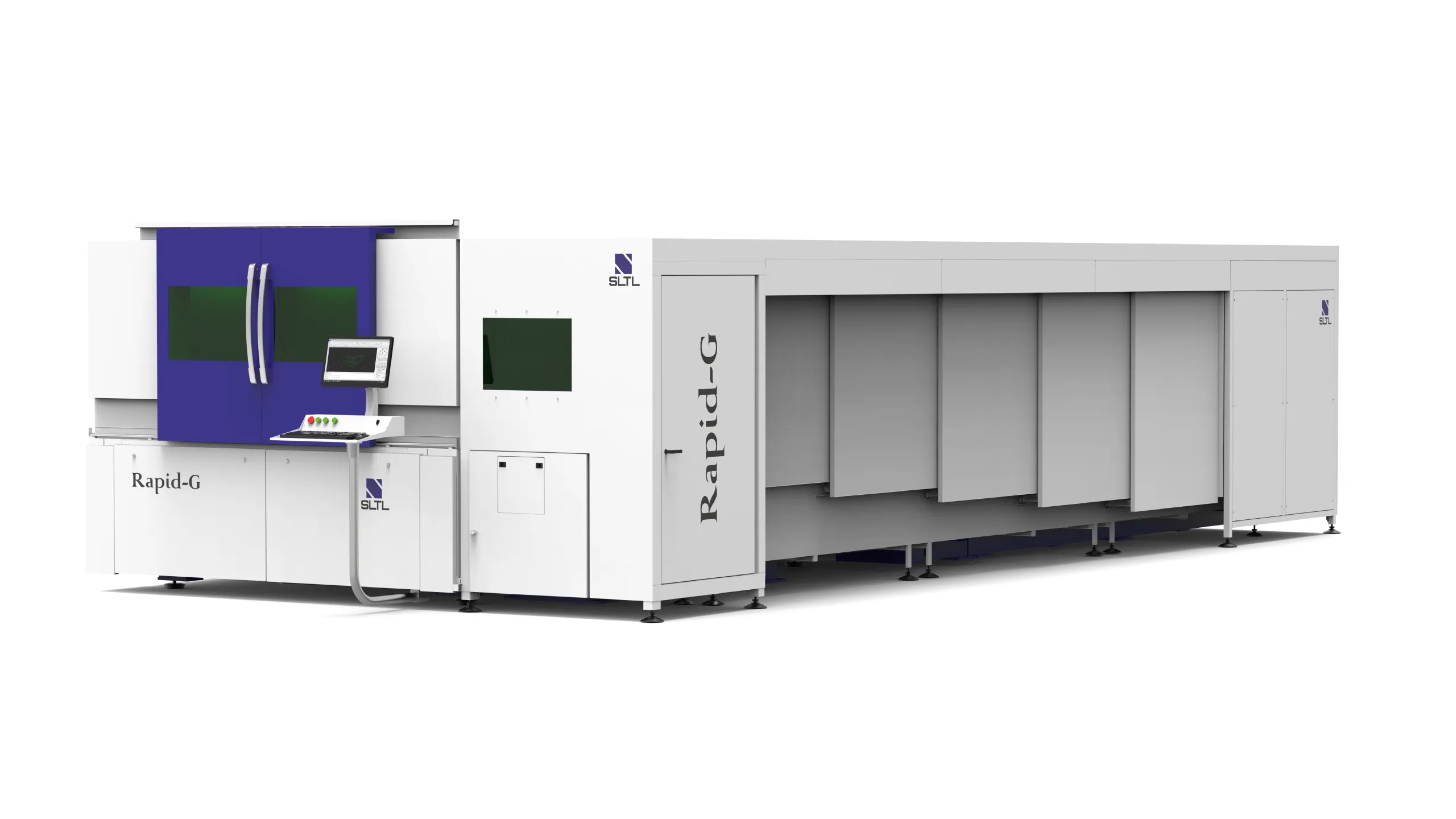

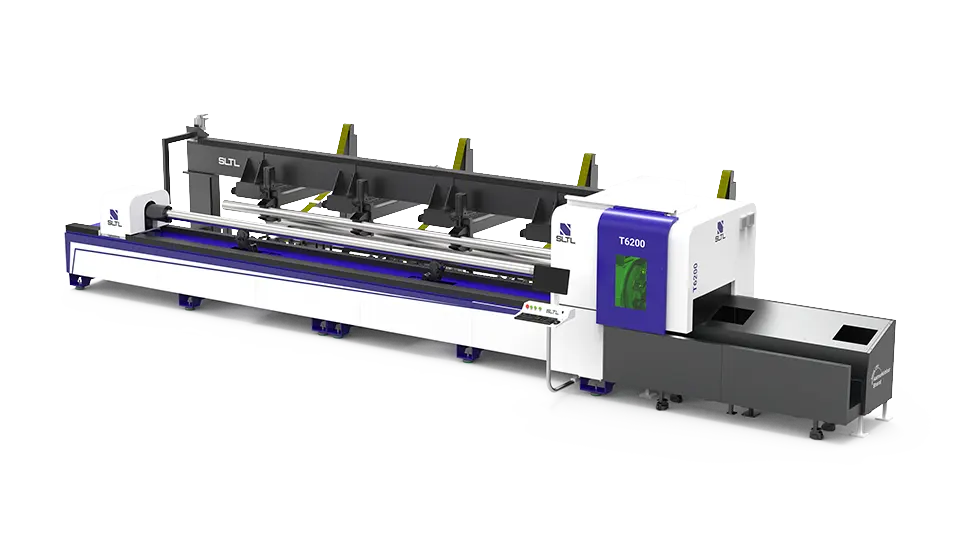

In the furniture industry, precision, aesthetics, and versatility are paramount. From intricate designs to robust structural components, manufacturers require cutting-edge solutions to achieve high-quality finishes across various materials and thicknesses. SLTL Group understands these demands and presents its advanced 2D Laser Cutting Machine and Tube Cutting Machine, designed specifically to cater to the evolving needs of furniture makers.

Our 2D Metal Laser Cutting Machine delivers unparalleled precision in sheet metal cutting, enabling manufacturers to create sleek, flawless designs with fine detailing. Whether working with stainless steel, mild steel, aluminum, brass, copper or other materials, these machines ensure superior edge quality and minimal material wastage, making them a cost-effective solution for modern furniture production.

For tubular structures, our Pipe Laser Cutting Machine brings unmatched efficiency in processing round, square, rectangular and other open section tubes. These machines are equipped with advanced automation, enabling seamless cutting of complex geometries and intricate patterns, ideal for furniture frames, decorative elements, structural components and many such furniture intricate designs. With high-speed operations and exceptional accuracy, our tube cutting solutions help manufacturers enhance productivity while maintaining design integrity.

By integrating SLTL’s cutting-edge laser technology, furniture makers can achieve intricate, high-quality designs with precision and speed.

Engineering Machinery

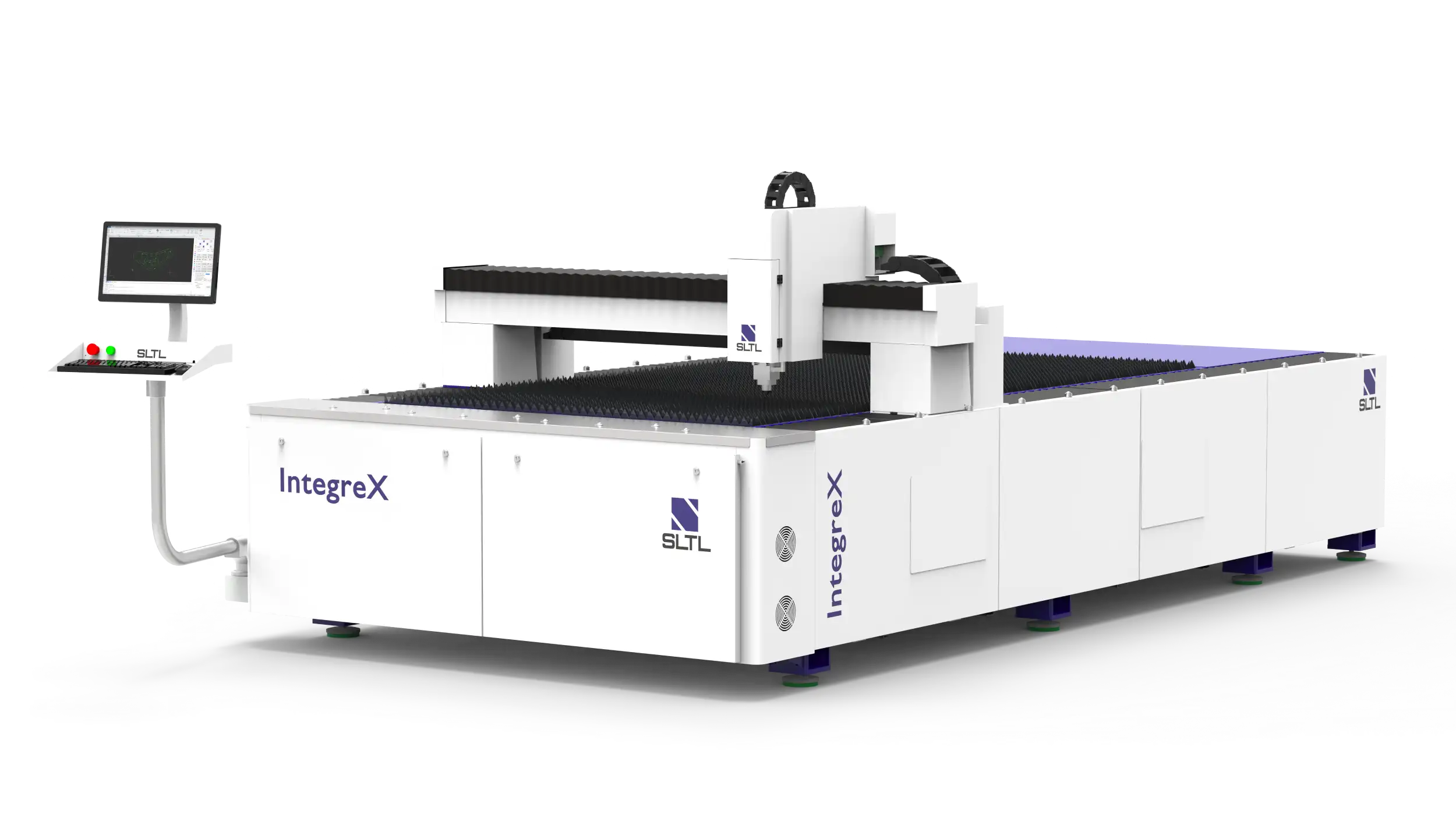

SLTL Group’s cutting-edge laser solutions are designed to meet the evolving demands of the engineering machinery industry, where precision, efficiency, and versatility are paramount. SLTL’s 2D and 3D laser cutting machine, along with our Tube Cutting Machine, offers unparalleled accuracy, enabling manufacturers to produce intricate components with minimal material wastage.

Our 2D Fiber Laser Cutting Machine is ideal for high-speed, high-precision sheet metal cutting, ensuring clean edges and optimized material usage. For industries that require multi-dimensional cutting, SLTL’s 3D Metal Laser Cutting Machine provides the flexibility to process complex geometries, offering a seamless solution for automotive, and heavy engineering applications.

Additionally, our Tube Laser Cutting Machine revolutionizes the fabrication of cylindrical, square, and irregular-shaped tubes, eliminating the need for multiple machining operations. Whether for structural frameworks, piping systems, or custom designs, these machines enhance productivity and reduce manual intervention.

With smart automation, IoT integration, and advanced laser technology, SLTL’s machines redefine efficiency, allowing businesses to scale operations while maintaining superior quality standards. Engineered for durability and precision, these systems help manufacturers tackle intricate designs with ease, ensuring faster production cycles and reduced operational costs.