SLTL – The World’s First manufacturer of Fiber Laser Cutting Systems, has introduced the ‘Vector’ fiber laser cutting machine, considering the specific needs of the metal cutting industry. The word “vector” itself essentially means “line”. Therefore, the machine’s design and the cutting process rely on lines to create the desired output. Thus, this machine provides a valuable function for sign makers and those working with digital graphics by cutting a wide range of substrates with high accuracy and quality. It’s perfect for cutting a wide range of materials with precision, mild steel, stainless steel, aluminium, brass, copper, Inconel, speciality alloys, as well as coated and textured metal sheets, may all be cut spectacularly with this futuristic laser cutting machine.

Ever since incorporation, we have been making our own way through futuristic technology and ground-breaking innovations.

This machine allows designs to be cut out of a variety of substrates with vector cutting’s high accuracy. The machine also has an automatic nozzle cleaning and replacement feature.

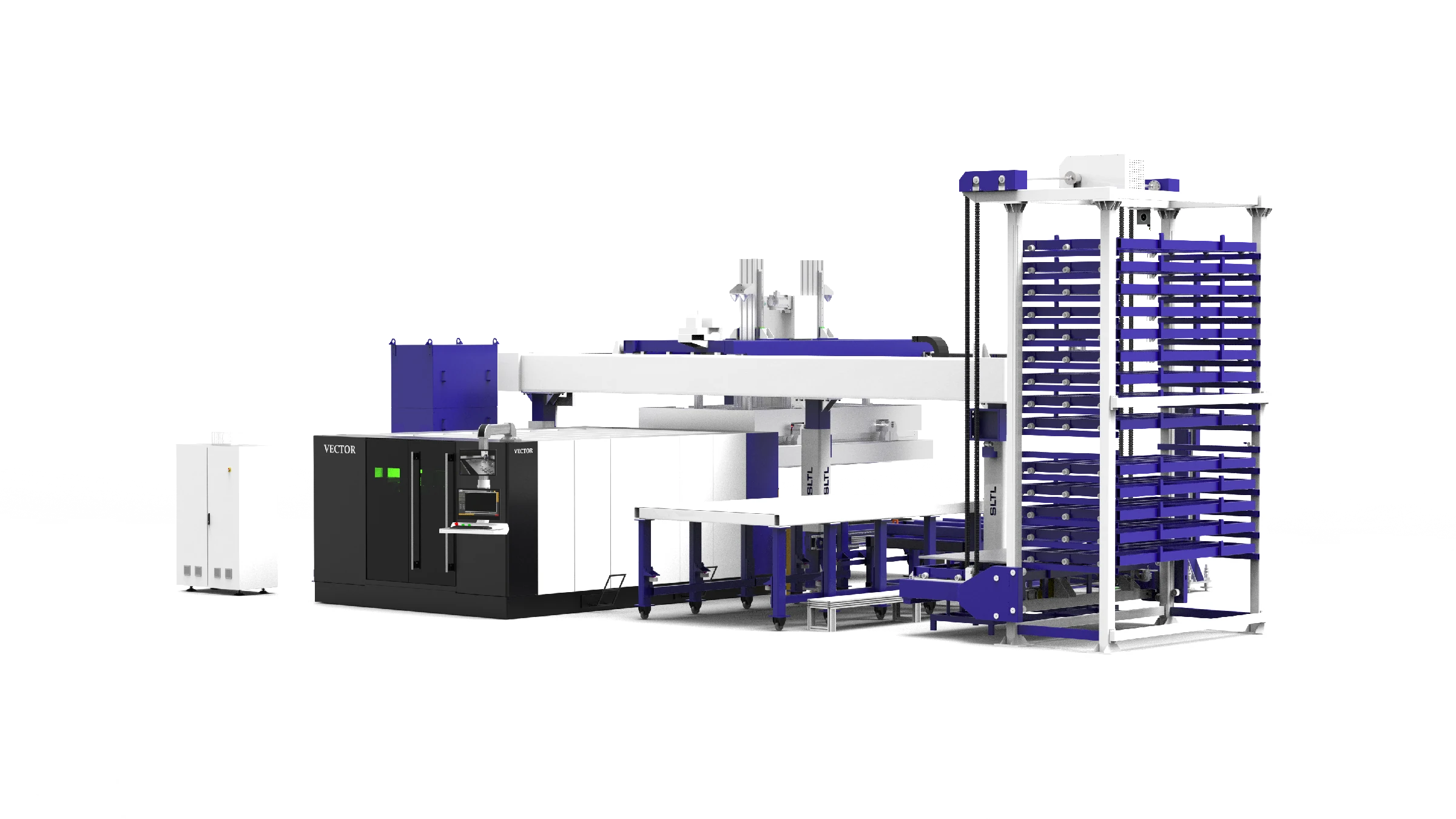

Vector is equipped with the benefits of loading and unloading automation which includes increased productivity, reduced labour costs, improved safety, minimized product damage, faster turnaround times, and enhanced overall supply chain efficiency. By automating these critical processes, businesses can achieve greater operational efficiency, reduce errors, and improve customer satisfaction by ensuring timely and accurate productivity.

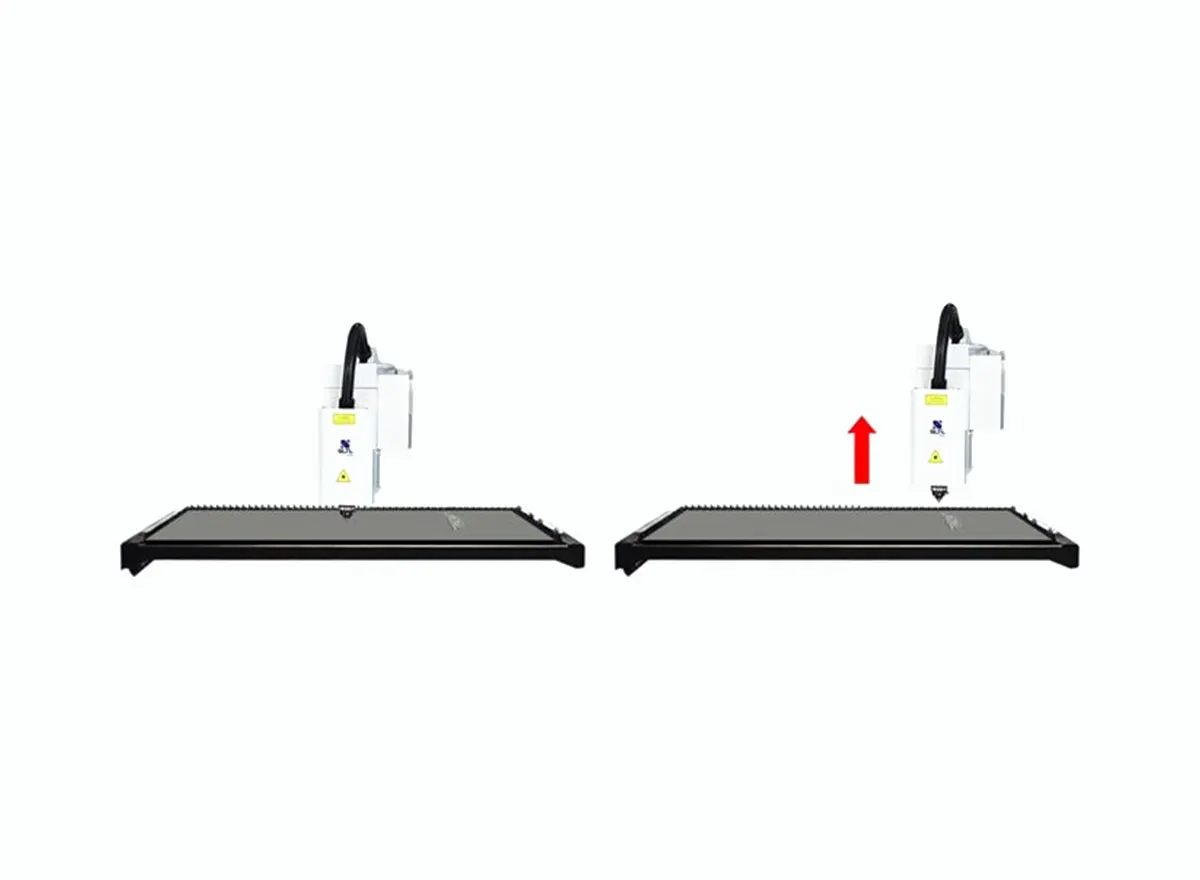

Vector provides complete reliable and safe working operation with its intelligent technology which has inbuilt sensors to scan for any protruding particles on the cutting table allowing the cutting head to automatically move to the home position in case of any collision between the workpiece and the head. In case of any such disturbances in the working profile, the smart technology helps to overcome the collateral damage – the workpiece and the cutting head by, stopping the laser head’s movement until the path is cleared.

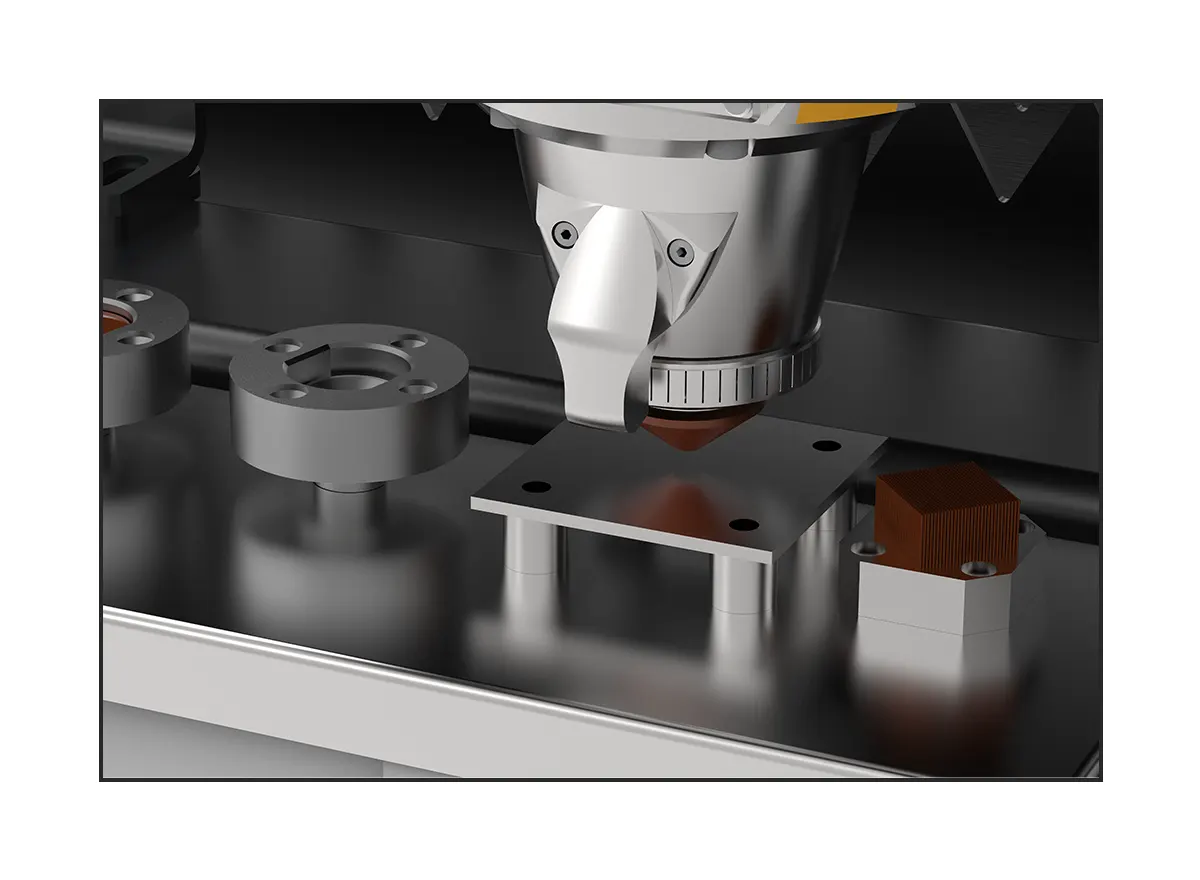

The system is upgraded for changing the nozzle automatically with a single operation. The nozzle changeover mechanism will work flawless for the finest metal processing and eliminating human error for nozzle changeover. The feature is responsible for a frictionless cutting experience with fewer operational efforts.

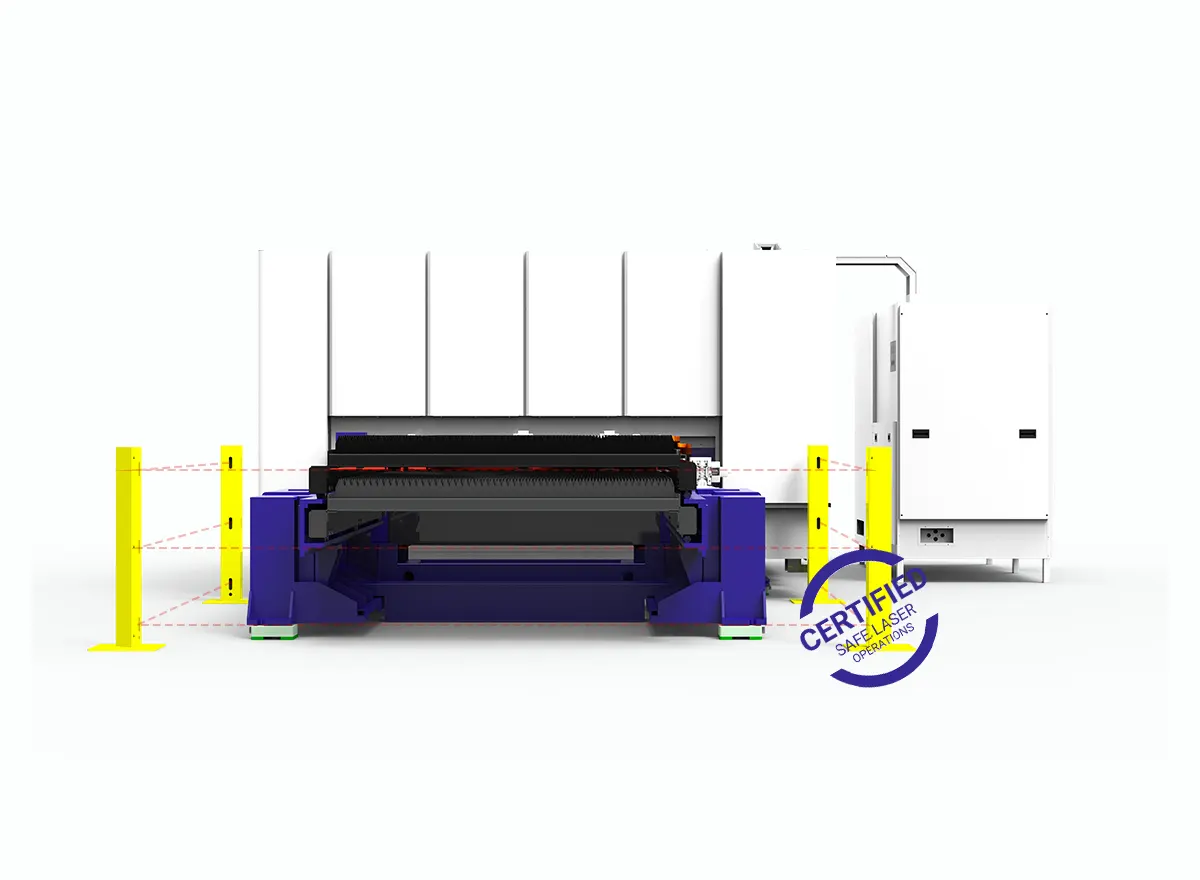

Though the laser machine utilizes a powerful laser, it is designed with supreme safety standards for secure process execution across the facilities. The CE Complied machines are designed and developed using a Class-1 laser safety enclosure structure to nullify the damages that may happen to the operators or nearby environment while the machine is in the operational stage.

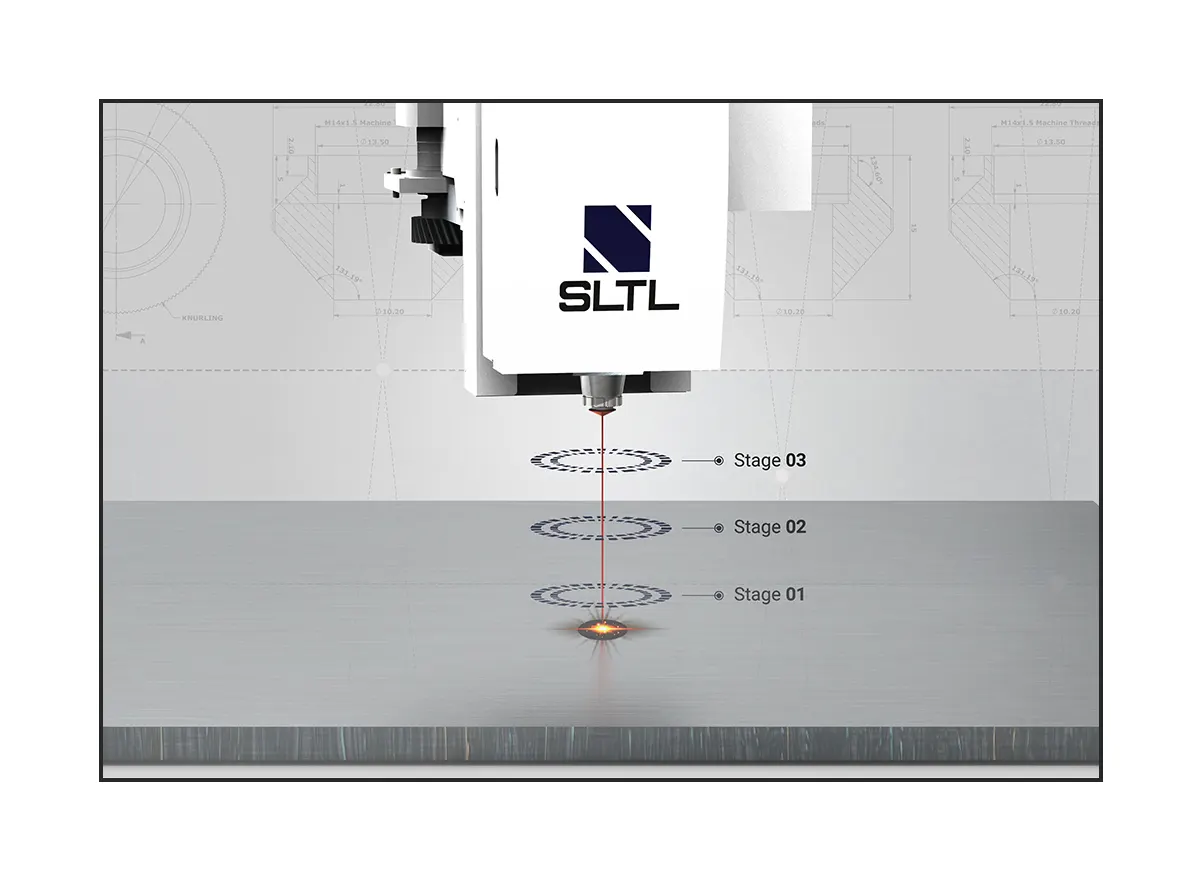

Even when there are many individual piercings, the method is reliable for extremely fast piercing, resulting in less idle time and eliminate the material deformation of thick sheets. 2 Stage Piercing remarkably improves the efficiency of the laser-cutting machine, by significantly reducing the piercing time. While, 3 Stage Piercing is one of the most advanced features of this robust Laser Cutting Machine, specifically designed to ensure the effective processing of higher material thicknesses.

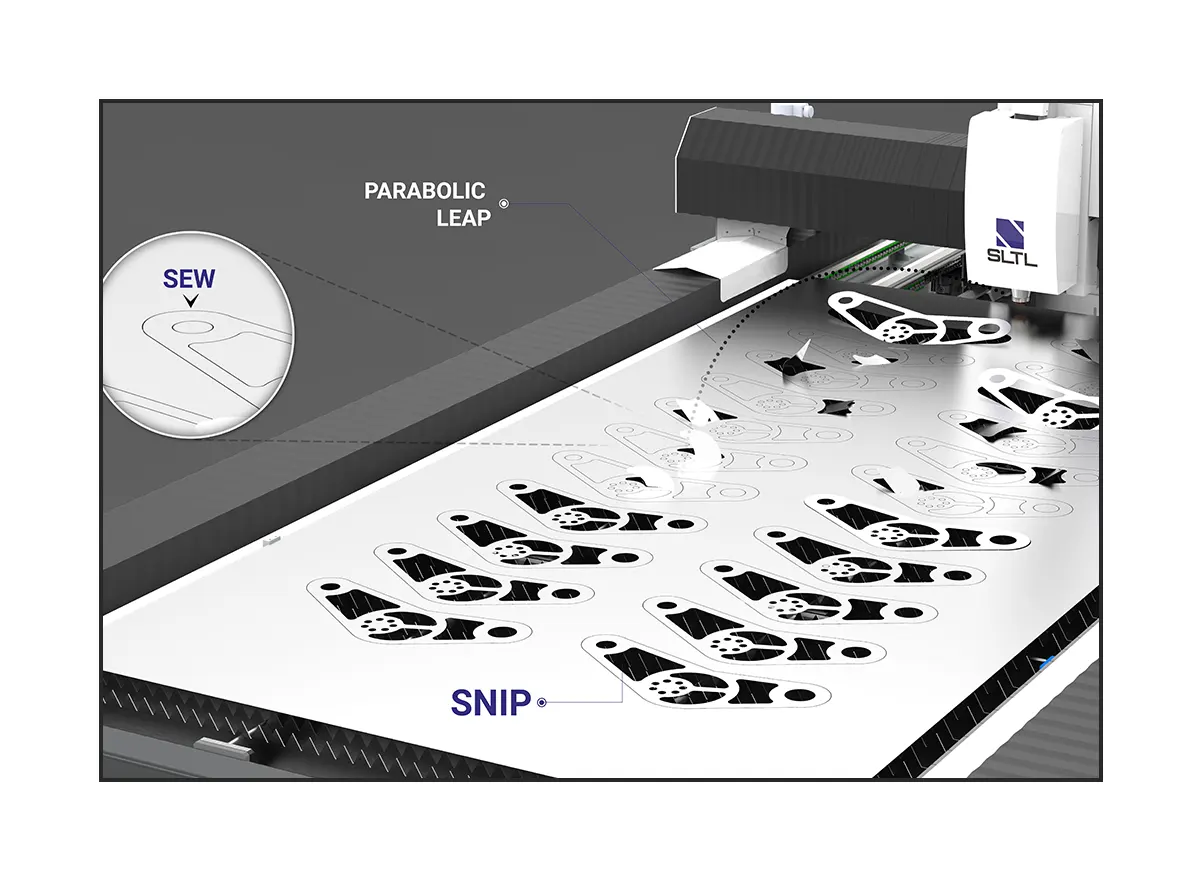

The anti-collision mechanism consists of snip, sew and parabolic leaps, this minimizes non-productive times which can happen due to parts tipping over when cutting thin sheet metal, and ensures that the sheet cut-out pieces do not collide with the laser head while processing and makes your machine permanently productive.

The Eco-friendly Vector comes with power-efficient technology, which ultimately reduces the running cost of the machine. The Fiber Laser System offers 50% energy savings among other laser cutting technologies, and state of art fume suction technology exceeds the fume suction methodology by removing more than 90% of fumes from the laser cutting environment. Thus making Vector the most efficient model for the metal-cutting process.

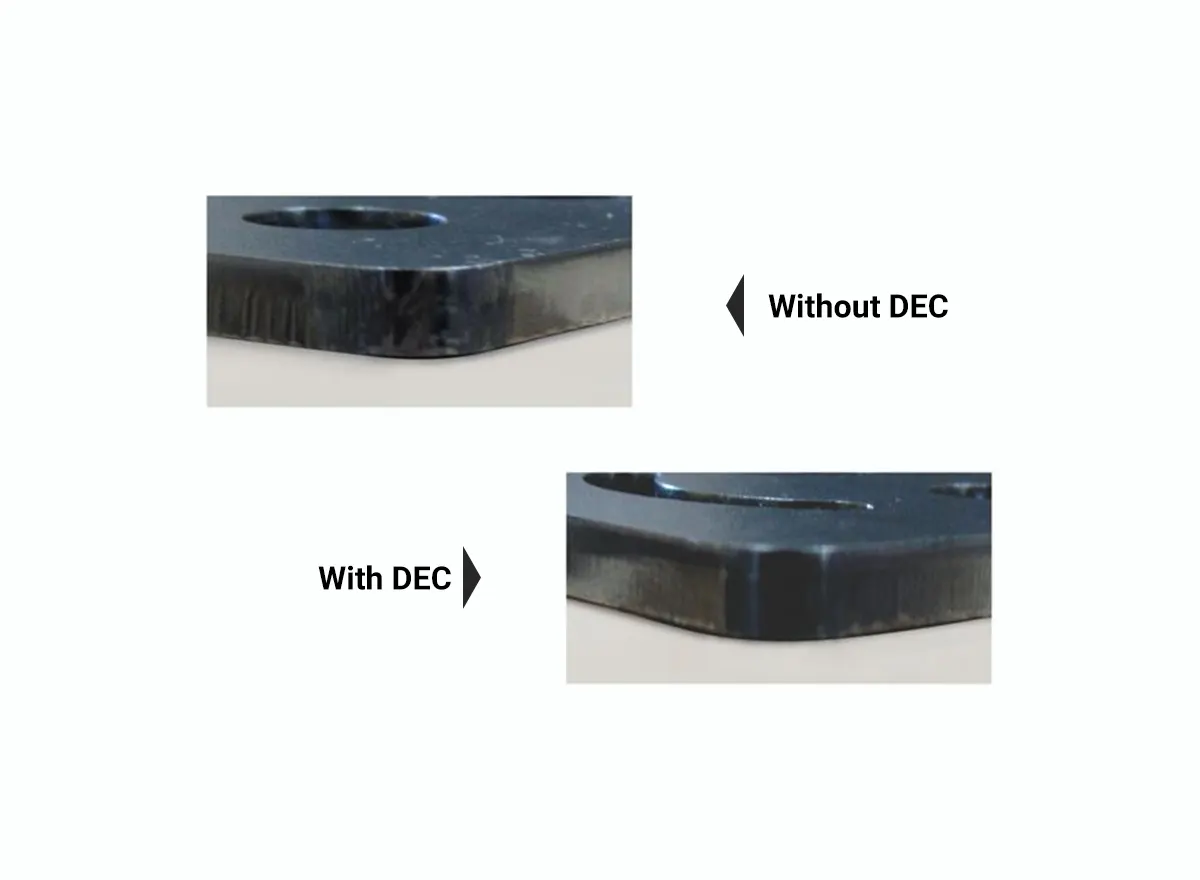

A laser, when properly focused and set for a material, cuts a part with a sharp edge. Dynamic Edge Control (DEC) decreases inflammation on the edges of the processing materials, synchronized laser with axial motion through the system. The cutting system operates laser power with the axis speed via the dynamic edge control (DEC) mechanism which reduces burning effects at the edges.

The pioneering fiber laser cutting machines are designed to ensure that enhanced Safety with a class 1 enclosure, light curtains, a hermetically sealed cabinet (lp55), and door interlocks. Laser safety windows keep the laser radiation intact inside the machine while the cutting process.

| Laser Power | 4 kW | 6 kW | 8 kW | 10 kW | 12 kW | 15 kW | 20 kW | 30 kW |

|---|---|---|---|---|---|---|---|---|

| Mild Steel (MS) (O2) | 22 (7/8″) | 25 (1″) | 28 (9/8″) | 30 (19/16″) | 40 (26/16″) | 45 (7/4″) | 50 (31/16″) | 60 (19/8″) |

| Mild Steel (MS) (N2 / Air) | 6 (1/4″) | 8 (5/16″) | 10 (3/8″) | 12 (1/2″) | 12 (1/2″) | 16 (5/8″) | 20 (13/16″) | 25 (1″)* |

| Stainless Steel (O2) | 10 (3/8″) | 10 (3/8″) | 10 (3/8″) | 10 (3/8″)* | 10 (3/8″) | 10 (3/8″) | 10 (3/8″) | 10 (3/8″) |

| Stainless Steel (N2 / Air) | 10 (3/8″) | 16 (5/8″) | 20 (13/16″) | 25 (1″) | 30 (19/16″) | 32 (5/4″) | 35 (11/8″)* | 40 (25/16″)* |

| Aluminium (Al) (N2) | 10 (3/8″) | 16 (5/8″) | 21 (13/16″) | 25 (1″) | 30 (19/16″) | 32 (5/4″) | 35 (11/8″)* | 40 (25/16″)* |

| Brass (Br) (N2) | 8 (5/16″) | 12 (1/2″) | 16 (5/8″) | 20 (13/16″) | 25 (1″) | 30 (19/16″) | 32 (5/4″)* | 35 (11/8″)* |

| Copper (Cu) (O2) | 6 (1/4″) | 8 (5/16″) | 10 (3/8″) | 12 (1/2″) | 16 (5/8″) | 18 (11/16″) | 20 (13/16″) | 22 (7/8″) |

| Galvanized Iron (Gl) (N2 / Air) # | 3 (1/8″)* | 3 (1/8″)* | 3 (1/8″)* | 3 (1/8″)* | 3 (1/8″)* | 3 (1/8″)* | 3 (1/8″) | 3 (1/8″) |

| Power Consumption** | 24 Kw | 32 kW | 40 kW | 48 kW | 56 kW | 68 kW | 85kW | 120kW |

| Working Area | 3015 | 4020 |

|---|---|---|

| X axis | 1550 (61″) | 2100 (82″) |

| Y axis | 3100 (122″) | 4100 (161″) |

| Z axis | 150 (6″) | 150 (6″) |

| Max. Acceleration | 3 G | 2 G |

| Simultaneous Speed | 210 m/min | 140 m/min |

| Position Accuracy | (±)0.050 mm/meter (0.002″) | (±)0.050 mm/meter (0.002″) |

| Repeatability | (±)0.020 mm/meter (0.001″) | (±)0.020 mm/meter (0.001″) |

| Work Piece Weight | 900 kg | 1650 kg |

* The quality of cut depends upon the attributes of metal, its surface properties and the conditions in which the cutting operation is done.

Metal with high thickness tend to have striation at the lower edges.

** The power consumption indicated in the table is measured in the machine’s peak performance. It includes the connected load of

laser source, controller, fume extractor and chiller.

# Galvanized Iron (GI) only comes up to 3mm thickness in market

Interested In a Product?

Pricing, Technical Data & More

World’s best high-speed fiber laser forming machines with precise and accurate processing for all your business requirements such as metal sheet cutting, welding, cleaning, marking etc.

Ever since incorporation, we have been making our own way through futuristic technology and ground-breaking innovations.

24*7 service support and technical assistance. You’re welcome to visit our office for other insights

E-30, Electronic Estate, G. I. D. C.,

Sector - 26, Gandhinagar - 382 028

Gujarat, India.