SLTL Group is a leading manufacturer of fiber laser metal fabrication tools and equipment, specializing in cutting-edge solutions for cutting, marking, and welding applications. Known for its innovation and precision, SLTL designs and develops high-performance fiber laser machines that cater to a wide range of industries, including automotive, aerospace, electronics, and jewelry.

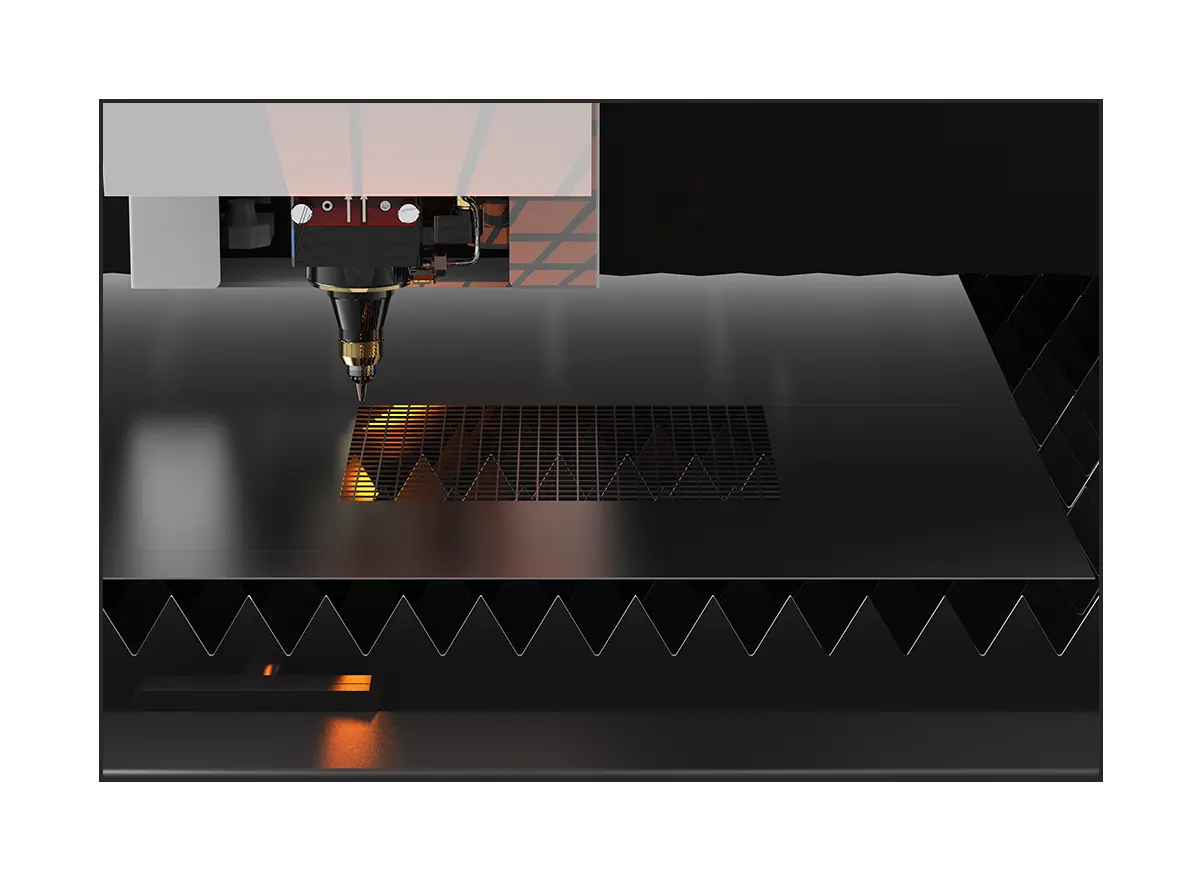

Their laser cutting machines deliver high-speed, high-accuracy processing of various metals, ensuring minimal material waste and superior edge quality. Laser marking systems by SLTL offer permanent, high-resolution marks for traceability, branding, and component identification on metal surfaces. For laser welding, SLTL provides robust systems that ensure deep penetration, minimal distortion, and clean welds, ideal for both thin and thick metal sheets.

With a focus on automation, efficiency, and sustainability, SLTL continues to drive advancements in laser technology, supporting industrial growth and helping manufacturers achieve higher productivity and precision in metal fabrication processes.

Ever since our incorporation, we have been making our own way through the domains and industries.

One of the key features to process high-speed cutting applications in Fiber laser cutting machines, FLYCUT performs the continuous cutting of the desired shape without lifting up the laser head giving a boost to the processing speed by reducing the head travel movements.

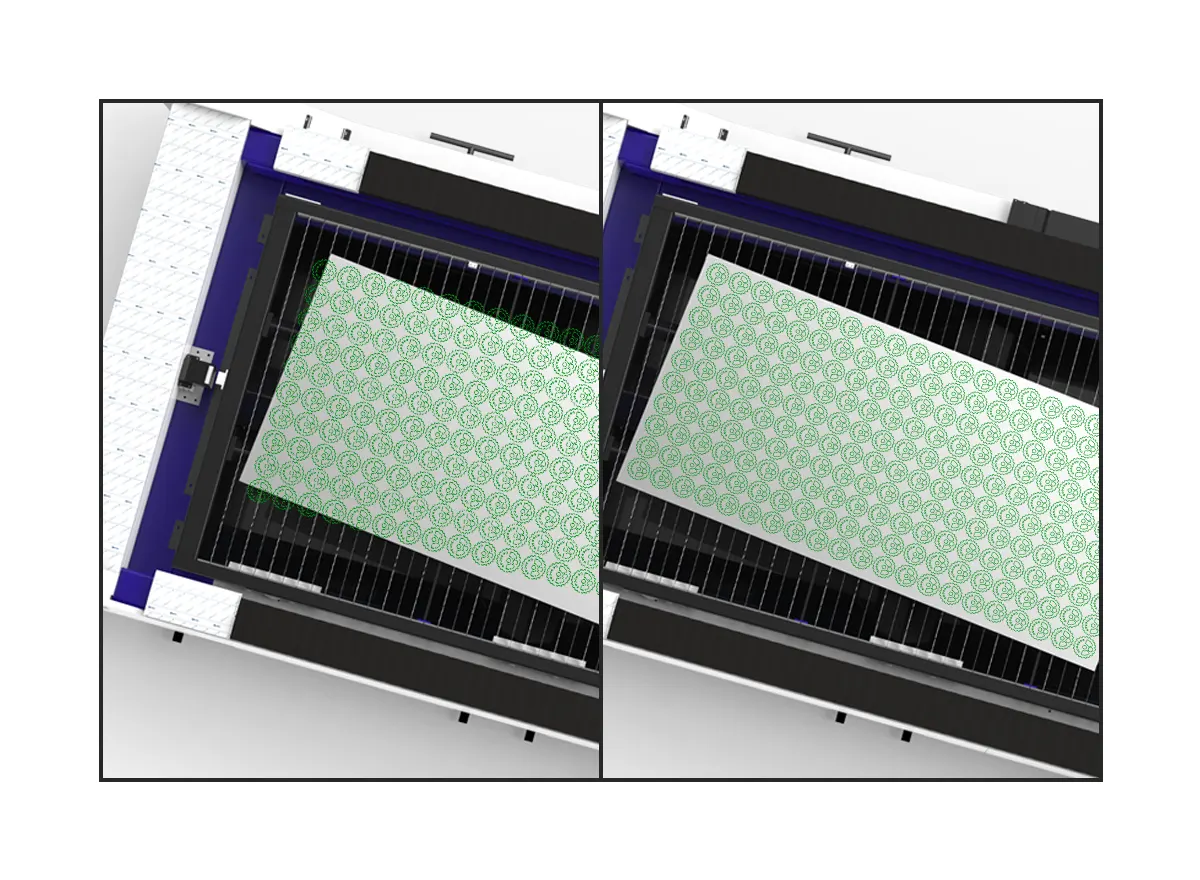

Smart nesting software with a high level of intuitiveness that focuses on reducing processing time not only for the smaller designs but also for the larger parts. The software provides flexibility for users to add, change or delete programs on the go. It helps in achieving maximum precision and high speed with laser outputs of its peak power.

Speed up the cutting process by eliminating the manual alignment of the sheet for each cutting operation. Auto-sheet orientation feature enables automatic orienting of the program to that angle in which the sheet has been kept which ultimately eliminates the non-productive time of arranging the sheet.

Smart nesting software with a high level of intuitiveness that focuses on reducing processing time not only for the smaller designs but also for the larger parts. The software provides flexibility for users to add, change or delete programs on the go. It helps in achieving maximum precision and high speed with laser outputs of its peak power.

This trio of benefits encapsulates the advantages of a product or solution that is not only cost-effective but also saves time and space. Being cost-efficient means it offers value for money, reducing expenses. It’s a time-saver, as it streamlines processes, boosting productivity. Its compact design ensures it doesn’t take up unnecessary space, making it practical and efficient for various applications.

With the ball support sheet loading/unloading helps in faster loading/unloading times and reduced downtime result in increased machine throughput, enhancing overall productivity and output.

With Zero Fillet Mode of a fiber laser cutting machine provides temperature control, extends the lifespan of critical components, enhances precision, improves energy efficiency, reduces downtime, boosts productivity, and contributes to overall safety during operation.

| Unit | Working Range 2D | Working Range 2D | ||

|---|---|---|---|---|

| 3015 | 4515 | |||

| Maximum Working Range | X Axis | mm | 1550 | 1550 |

| Y Axis | mm | 3100 | 4600 | |

| Z Axis | mm | 100 | 100 | |

| Maximum Workpiece Weight | kgs | 750 | 1100 | |

| Positioning Precision | mm/meter | ±0.05 | ±0.05 | |

| Repeatability | mm/meter | ±0.02 | ±0.02 |

| Laser Power | 1 kW | 1.5 kW | 2 kW | 3 kW |

|---|---|---|---|---|

| Mild Steel (MS) | 10 (3/8″) | 12 (1/2″) | 16 (5/8″) | 20 (3/4″) |

| Stainless Steel (SS) (O2) | 6 (1/4″) | 8 (5/16″) | 10 (3/18″) | 10 (3/8″) |

| Stainless Steel (SS) (N2) | 3 (1/8″) | 4 (5/32″) | 6 (1/4″) | 8 (5/16″) |

| Aluminum (AL) | 2** | 3 (1/8″) | 5 (3/16″) | 8 (5/16″) |

| Brass (Br) | 3** | 3 (1/8″) | 5 (3/16″) | 6 (7/32″) |

| Copper (Cu) | 2** | 2 (1/16″) | 3 (1/8″) | 5 (3/16″) |

| Galvanized Iron (GI)# | 3 (1/8″)* | 3 (1/8″)* | 3 (1/8″)* | 3 (1/8″)* |

| Power Consumption** | 10 kW | 12 kW | 17 kW | 20 kW |

*The quality of the cut depends upon the attributes of the metal, its surface properties and the conditions in which cutting operations are done.

Metals with high thickness tend to have striation at lower edges.

** The power consumption indicated in the table is measured by the machine’s peak performance. It includes the connected load of the laser source, controller, fume extractor and chiller.

***Maximum thickness of full-size sheet is limited by weight carrying capacity of respective variant.

# Galvanized Iron (GI) only comes up to 3mm thickness in market.

Fume Suction

Class 1 Enclosure

Pallet Changer

Tube Cutting Mechanism

Filtered Fume Extractor

Auto Focus Cutting Head

Light Curtain

Support

Online Service Response 100%

Physical Response

Delighted Customers

Interested In a Product?

Pricing, Technical Data & More

World’s best high-speed fiber laser forming machines with precise and accurate processing for all your business requirements such as metal sheet cutting, welding, cleaning, marking etc.

Ever since incorporation, we have been making our own way through futuristic technology and ground-breaking innovations.

24*7 service support and technical assistance. You’re welcome to visit our office for other insights

E-30, Electronic Estate, G. I. D. C.,

Sector - 26, Gandhinagar - 382 028

Gujarat, India.