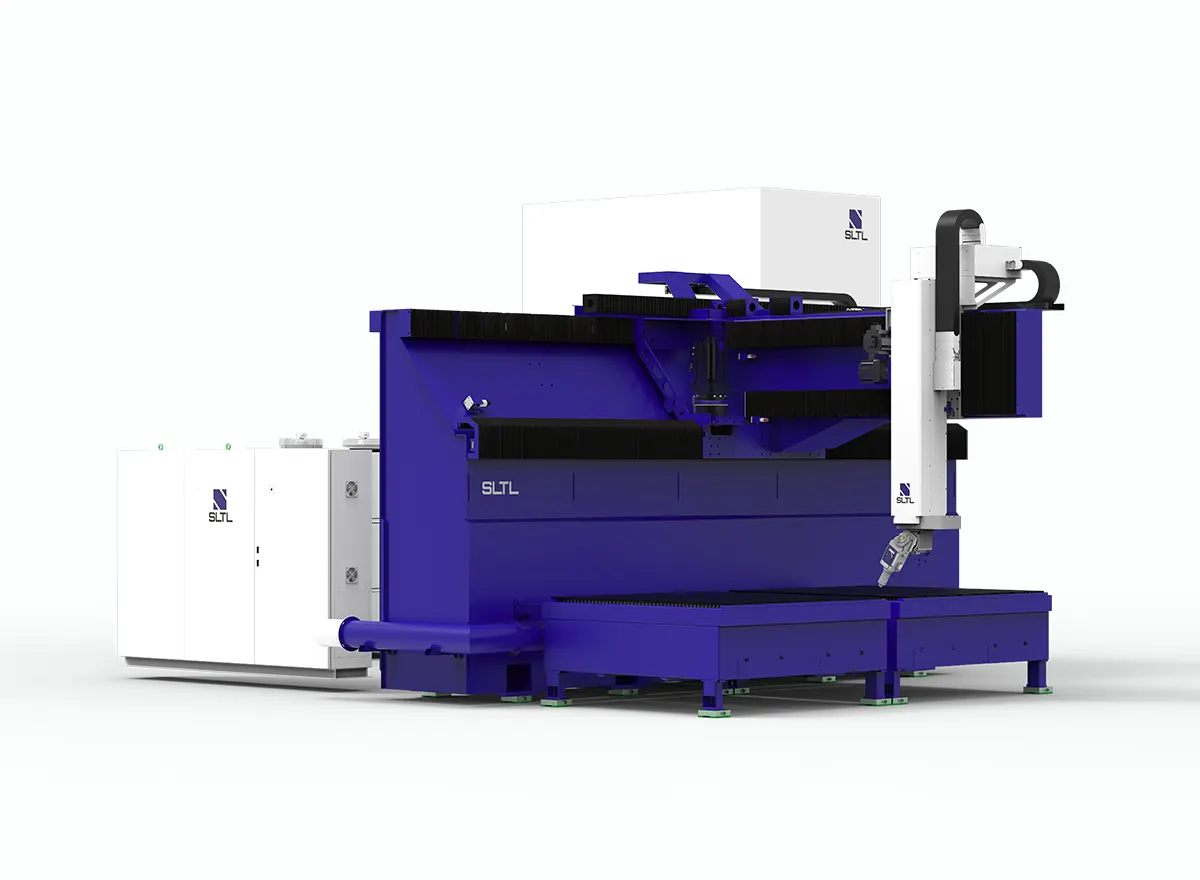

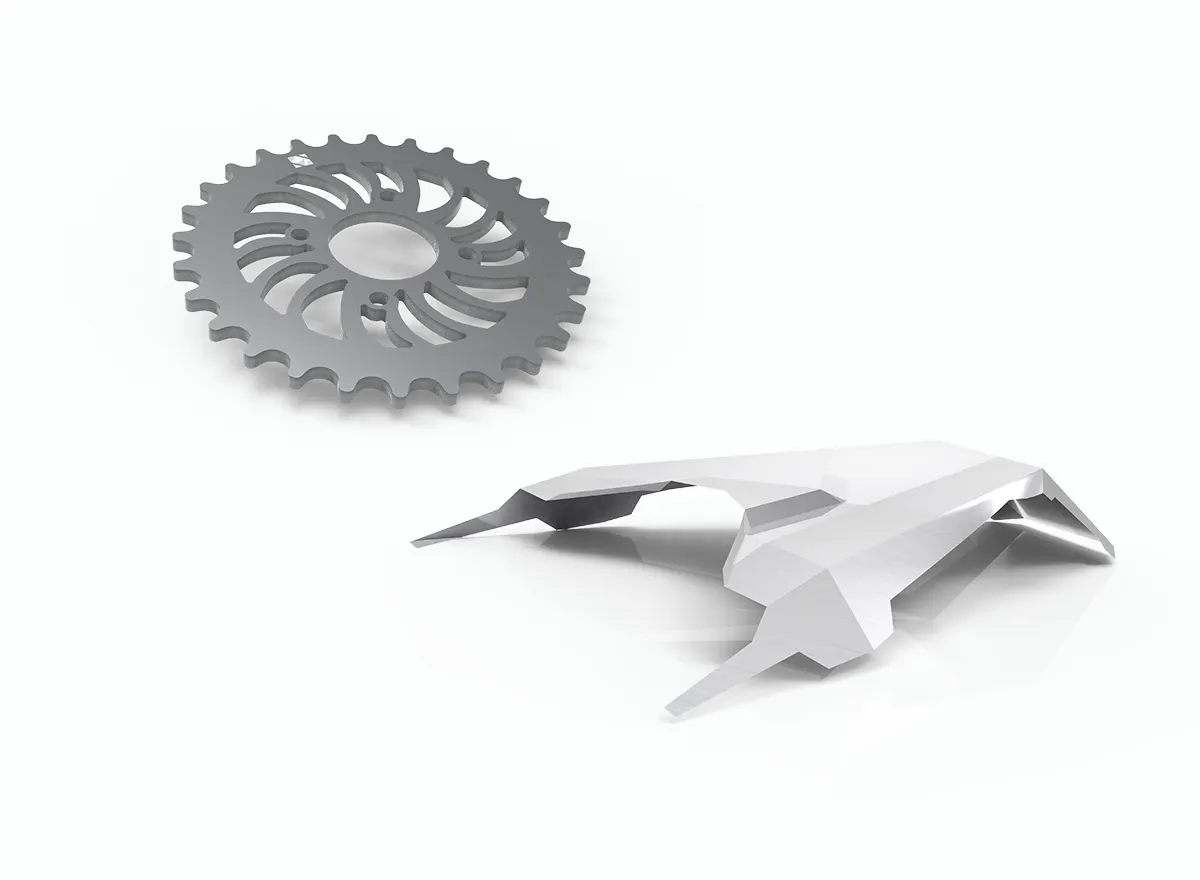

SLTL is the Leading Manufacturer of 3D Laser Cutting systems. The innovation leaders introduced 5 axis laser cutting machine- X5, to address various problems. The futuristic machine is capable of cutting any complex part because of its 5 axis advanced technology. Precisely performing application on Stainless Steel, Mild steel, Aluminium, Brass, Copper & other metals, X5 can reach critical points on the components by adjusting it. The complex cutting task is made easy by just one-time programming which eliminates other systems for component adjustments. This high-power 3D laser cutting machine could rapidly operate over diverse components.

Ever since incorporation, we have been making our own way through futuristic technology and ground-breaking innovations.

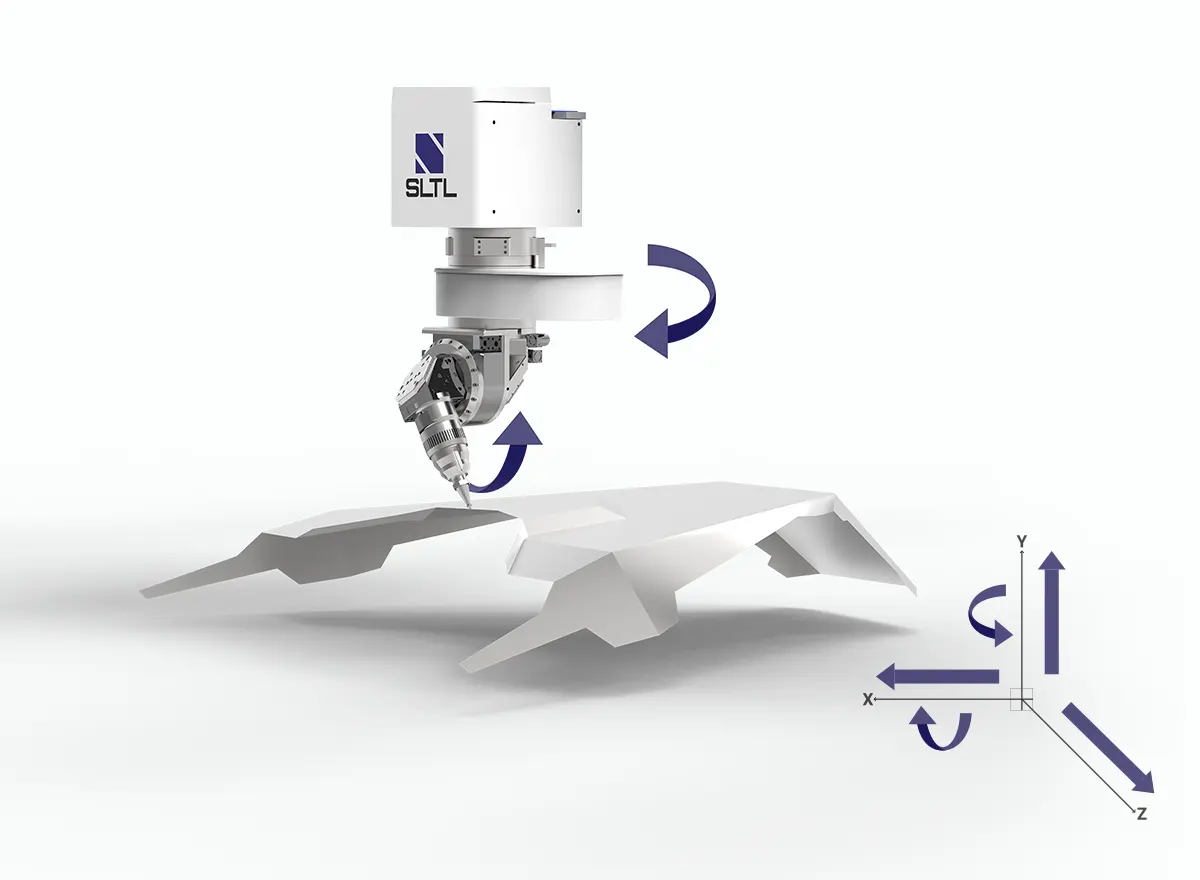

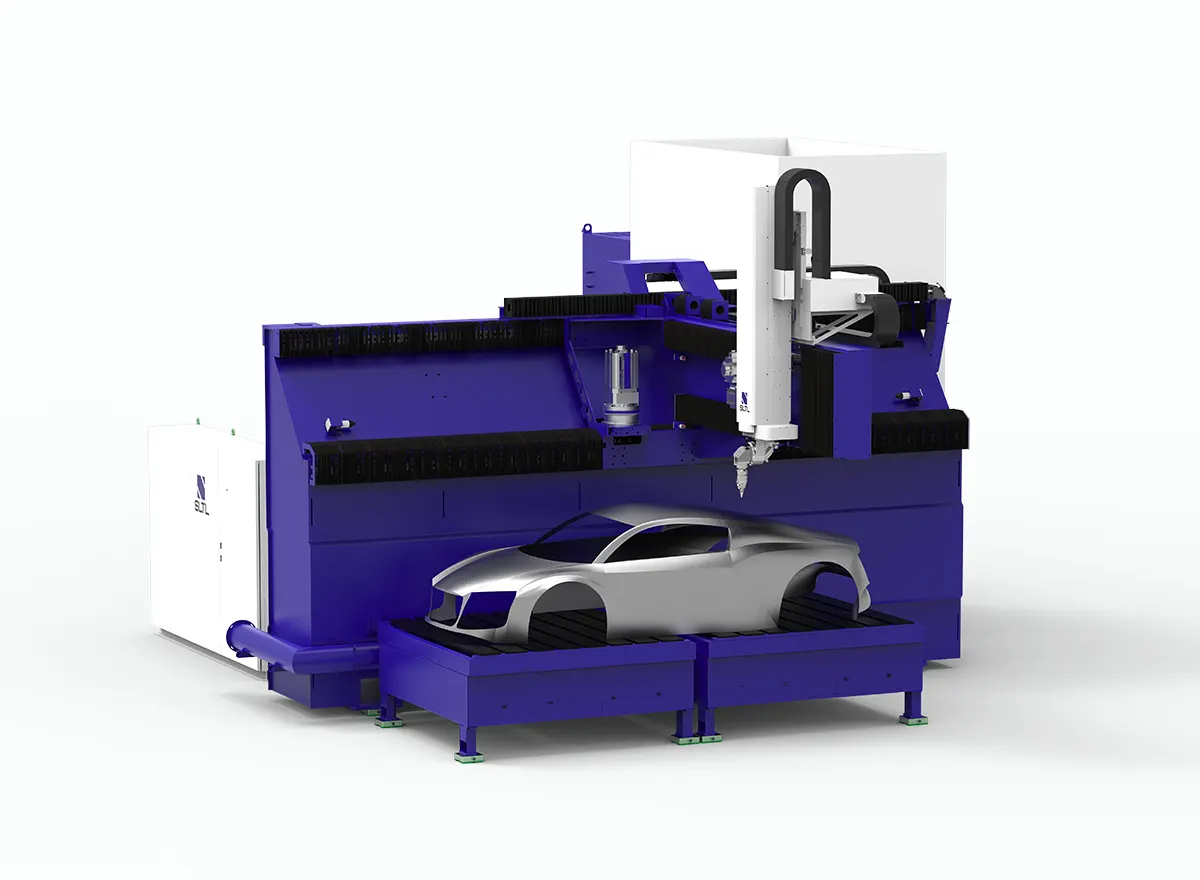

X5 is can perform Laser Cutting on complicated profiles with its flexibility of 5-axis movement. The advanced technology can precisely cut the metal structures in a minimal time frame enhancing productivity.

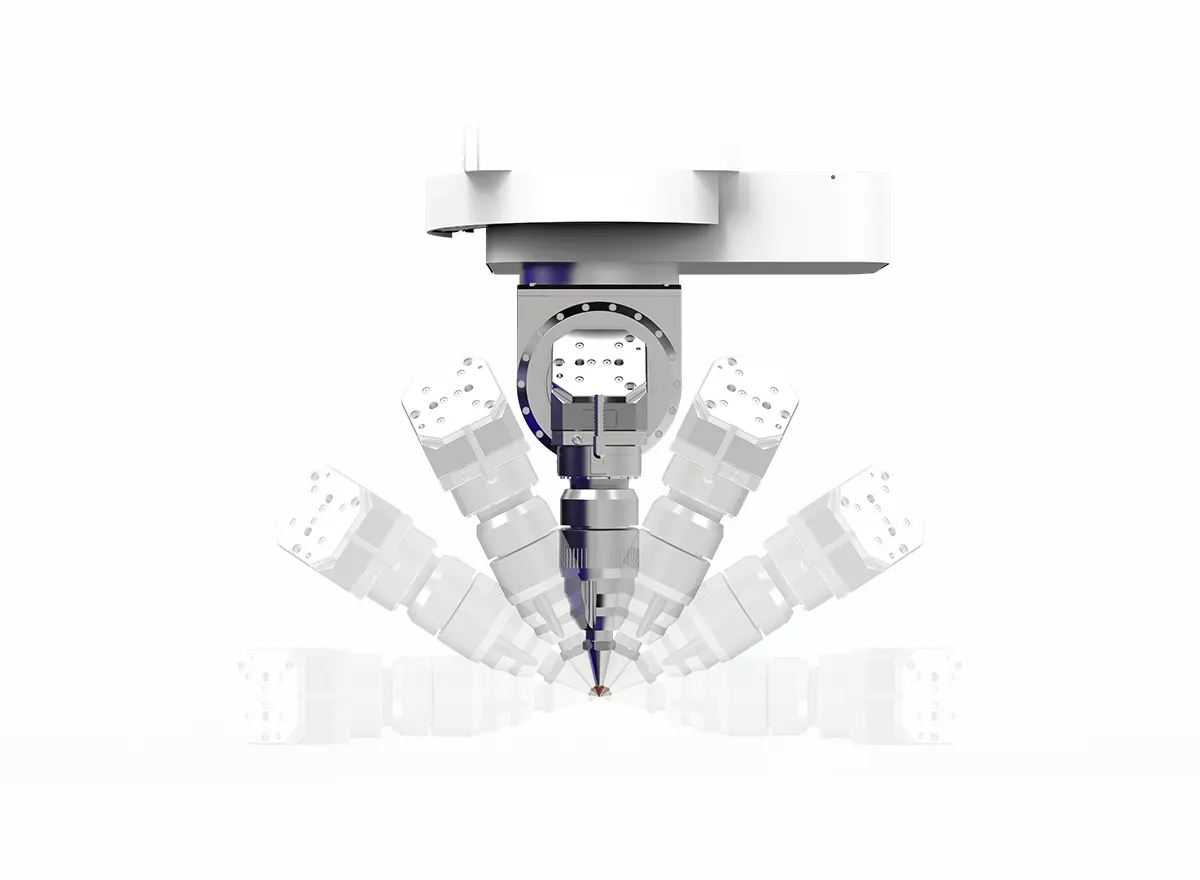

The cutting precision of the X5’s 5-axis allows it to cut complex forms with ease, thanks to its innovative design. By modifying and precisely cutting the components to the appropriate design, it is able to traverse difficult operational spaces and get to vital parts of the assembly. Instead of only the standard X, Y, and Z axis this system also features additional A and C axis, greater adaptability is made possible in this way.

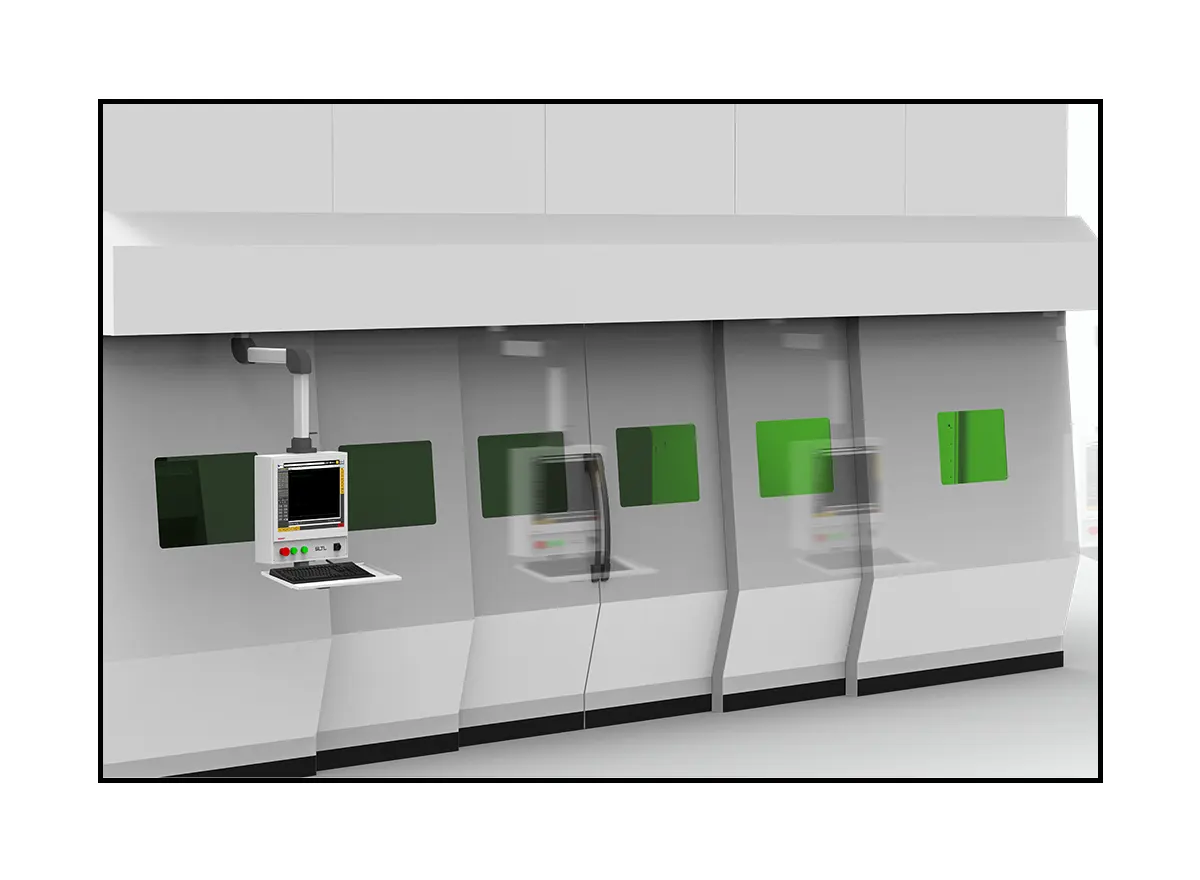

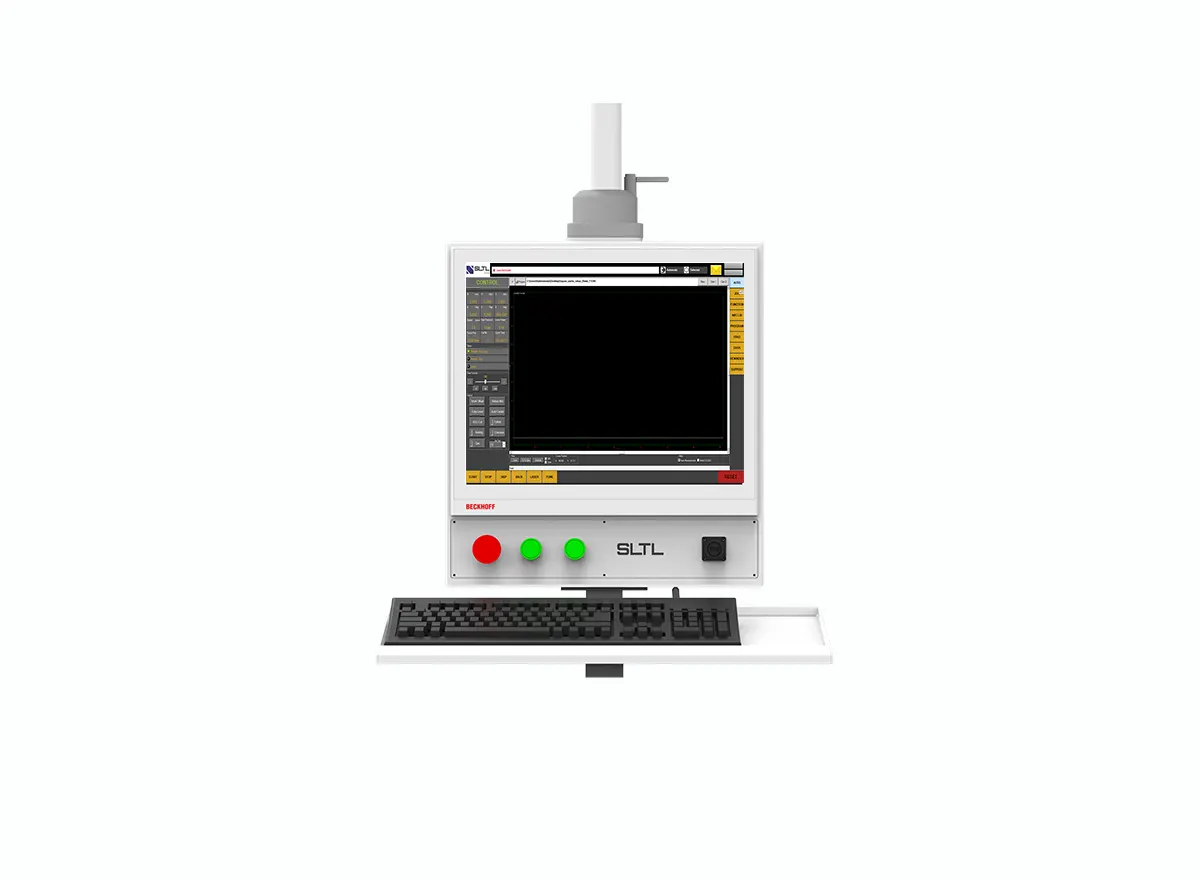

A machine that keeps you truly contented, can be operate from either of the sides with a flexible control panel that is feasible to move from one end to another for an enhanced experience. In order to provide greater operational flexibility, the control panel can be slide along the length of the working area.

The tool center point function makes the X5 a perfect fit for you as it ensures the most accurate processing, by the interpolation of all 5 axis at a single point. Its zero-angle accuracy is the best fit to cut the components in lesser time and ensure the consistent cutting quality of the job for years to come.

Built with the most advanced technology, X5 can flexibly cut the most intricate shapes while working on the 5-axis movement. It can cover complex spaces in operation & can reach critical points on the components by adjusting them and accurately cutting the desired design.

The complex cutting task is made easy by just one-time programming, eliminating other systems’ requirements for component adjustments. This high-power Fiber Laser cutting machine is designed to rapidly cut complicated profiles and 3D components with utmost precision and reduces human error.

The most versatile 3D Laser Cutting machine has a robust stable structure with good stiffness and gantry-based mobility that enhances quick dynamic reaction. Its sturdy construction makes it a must-have for 3D multi-tasking metal makers.

The 3D Fiber Laser Machine; X5 is developed to offer highly accurate cutting capabilities while maintaining the industry’s most energy-efficient footprint. With its high-performance motion system and fiber laser source, the 5-axis machine achieves a level of quality and throughput that is unprecedented for any other laser system.

Exceptional hardware-software integration allows the X5 laser cutting machine to cut materials at high speeds with extreme precision. This power-packed system is a perfect fit to enhance productivity and top the charts processing intricate forms and contours much more efficiently by the clever piercing mechanism. Enhanced process monitoring and error-free cutting are made possible by rapid positioning speeds and dynamic axis controls.

Go places with SLTLs X5 without the constant stress of processing large parts and even complex fixtures. Unleash the maximum potential while you are cutting heightened components, complicated job shapes or even special profiles. The z-axis is extended at the desired length to provide versatility for reaching out to the extreme corners and quickly cutting delicate shapes efficiently.

X5 achieves the best-cut quality at a sheer speed to continuously cut 2D or 3D structures in no time for a pre-defined area. The operator can relatively reduce the working time and thus experiences an increasing trend in productivity.

| Unit | 3015 | 4020 | |

|---|---|---|---|

| Laser Power | kW | 2 – 4 | 2 – 4 |

| X Axis Travel | mm (inch) | 1500 (59.05″) | 2000 (78.74″) |

| Y Axis Travel | mm (inch) | 3000 (118.11″) | 4000 (157.48″) |

| Z Axis Travel | mm (inch) | 650 (25.59″) | 650 (25.59″) |

| C Axis Travel | degree | ± Endless | ± Endless |

| A Axis Travel | degree | ± 135 | ± 135 |

| Work Envelope (3D) | mm | 2550 (100.3″) X 1050 (41.3*) X 650 (25.5″) | 3550 (139.7″) X 1550 (61″) X 650 (25.5″) |

| Maximum Sheet Weight | kg (lb) | ~ 750 (1653) | ~ 1100 (2425) |

| Unit | 3015 | 4020 | |

|---|---|---|---|

| Laser Power | kW | 2 – 4 | 2 – 4 |

| Maximum Speed X Axis | m/min. (in/min) | 80 (3149.61″) | 80 (3149.61″) |

| Maximum Speed Y Axis | m/min. (in/min) | 80 (3149.61″) | 80 (3149.61″) |

| Maximum Acceleration X Axis | m/s2 | 10 (1G) | 10 (1G) |

| Maximum Acceleration Y Axis | m/s2 | 10 (1G) | 10 (1G) |

| Positional Accuracy | mm/m (in/m) | ± 0.1 (± 0.004″) | ± 0.1 (± 0.004″) |

| Repeatability | mm/m (in/m) | ± 0.05 (± 0.002″) | ± 0.05 (± 0.002″) |

| C & A Axis Accuracy | Arc Second | ± 3 | ± 3 |

| Unit | 3015 | 4020 | |

|---|---|---|---|

| Laser Power | kW | 2 – 4 | 2 – 4 |

| Rotation Range C Axis | degree | ± Endless | ± Endless |

| Maximum Speed C Axis | degree/sec | 720° | 720° |

| Maximum Acceleration C Axis | degree/s2 | 3600° | 3600° |

| Swivel Range A Axis | degree | ± 135 | ± 135 |

| Maximum Speed A Axis | degree/sec | 720° | 720° |

| Maximum Acceleration A Axis | degree/s2 | 3600° | 3600° |

| Drive Unit C & A Axis | Torque Motor / HG Drives | Torque Motor / HG Drives | |

| Measuring System C & A Axis | Absolute | Absolute | |

| Weight of Head | kg | < 40 | < 40 |

*All the above Figures are in mm (Millimeters).

Sahajanand Laser Technology Ltd. reserves the right to make changes without any prior intimation or notice.

Support

Online Service Response 100%

Physical Response

Delighted Customers

Interested In a Product?

Pricing, Technical Data & More

World’s best high-speed fiber laser forming machines with precise and accurate processing for all your business requirements such as metal sheet cutting, welding, cleaning, marking etc.

Ever since incorporation, we have been making our own way through futuristic technology and ground-breaking innovations.

Explore our blogs for a resourceful insight into the infinite opportunities of the laser world.

Fiber Laser cutting is one of those diversified laser solutions that is highly prioritized by many of the industries.

Speaking of mighty production machines, Laser cutting machines are one of the major metal processing machines used across the globe.

Laser technology is revolutionizing and making the automotive sector more sustainable.

24*7 service support and technical assistance. You’re welcome to visit our office for other insights

E-30, Electronic Estate, G. I. D. C.,

Sector - 26, Gandhinagar - 382 028

Gujarat, India.