One of the many research experiments conducted by the in-house team at SLTL suggests that laser welding in comparison to conventional welding provides greater welding strength

While train network in India is very widespread and takes a load of frequent moving passengers as well as the transportation of heavy cargo for the booming industrial demands. India’s major energy sector is relied on the coal and thermal fossil fuels which were readily made available to the industry through train network. Under such strain the railways always look to stretch its routes and capacity to the maximum.

Recently, the Indian Train bogie manufacturing company or ICF Indian Coach Factory surpassed the long time industry leader to become the world’s largest train bogie manufacturing unit by producing more than it’s expected output in the financial year 2018-19. Due to versatile Indian terrain the Railways seem to be the perfect transportation for people and cargo services. The industry is facing a challenge to upgrade the current capacity to build the Train bogies with increased strength and ergonomics.

To understand the scenario, we have to look at the existing technology used to weld train bogie manufacturing. Understanding the scope of improvements and alternatives that could be plugged-in.

Before the introduction to fiber laser technology, the industry employed MIG and TIG welding for side panel welding. These techniques were rather outdated and provided very minimum upgrades in the past decade. The application of these conventional methods, other processes has to be clubbed to achieve the rising demands for aesthetics and strength. Here are some disadvantages of the systems:

- The use of inert gas in welding can prove costly

- MIG welding requires great dexterity and skill

- Significant amounts of heat are required during GMA welding

- Heat is transferred to the metal workpiece and can cause distortion and also a change in the structure of the metal which can result in weaknesses in welds

- Susceptible to contaminants

- High set up costs

- UV rays can cause burns

- Is limited to draught free conditions

- Requires high skill

- Equipment and consumables are costly

- Not portable and unsuitable for outdoor welding

- Impossible to use in vertical or overhead positions due to the liquidity of the weld

A Fresh Approach

We at SLTL Group focus on continuous Innovation and consider innovation a never ending process. One of the many research experiments conducted by the in-house team at SLTL suggests that laser welding in comparison to conventional welding provides greater welding strength (up to 59%). The team conducted industry standard and specialised tests for ensuring the superior quality of welding joint. Team achieved successful results in Tensile and bend test, Hardness test, Macrostructure Examination, Liquid Penetration Examination, 180 degrees bend test of the weld joint. Henceforth, increase in the safety factor of a wagon. With the machine’s ability to make streamlined welding, overall aesthetics improved.

- Weld strength: The laser weld is narrow with an excellent depth-to-width ratio and higher strength.

- Heat affected zone: The heat affected zone is limited, and due to rapid cooling, the surrounding material is not annealed.

- Metals: Lasers successfully weld carbon steel, high strength steel, stainless steel, titanium, aluminum, and precious metals as well as dissimilar materials.

- Precision work: The small, tightly controlled laser beam permits accurate micro-welding of miniature components.

- Deformation: Parts have minimal deformity or shrink.

- No contact: No physical contact between the material and laser head.

- One sided welding: Laser welding can replace spot welding requiring access from one side only.

- Scrap: Laser welding is controllable and generates low volumes of scrap.

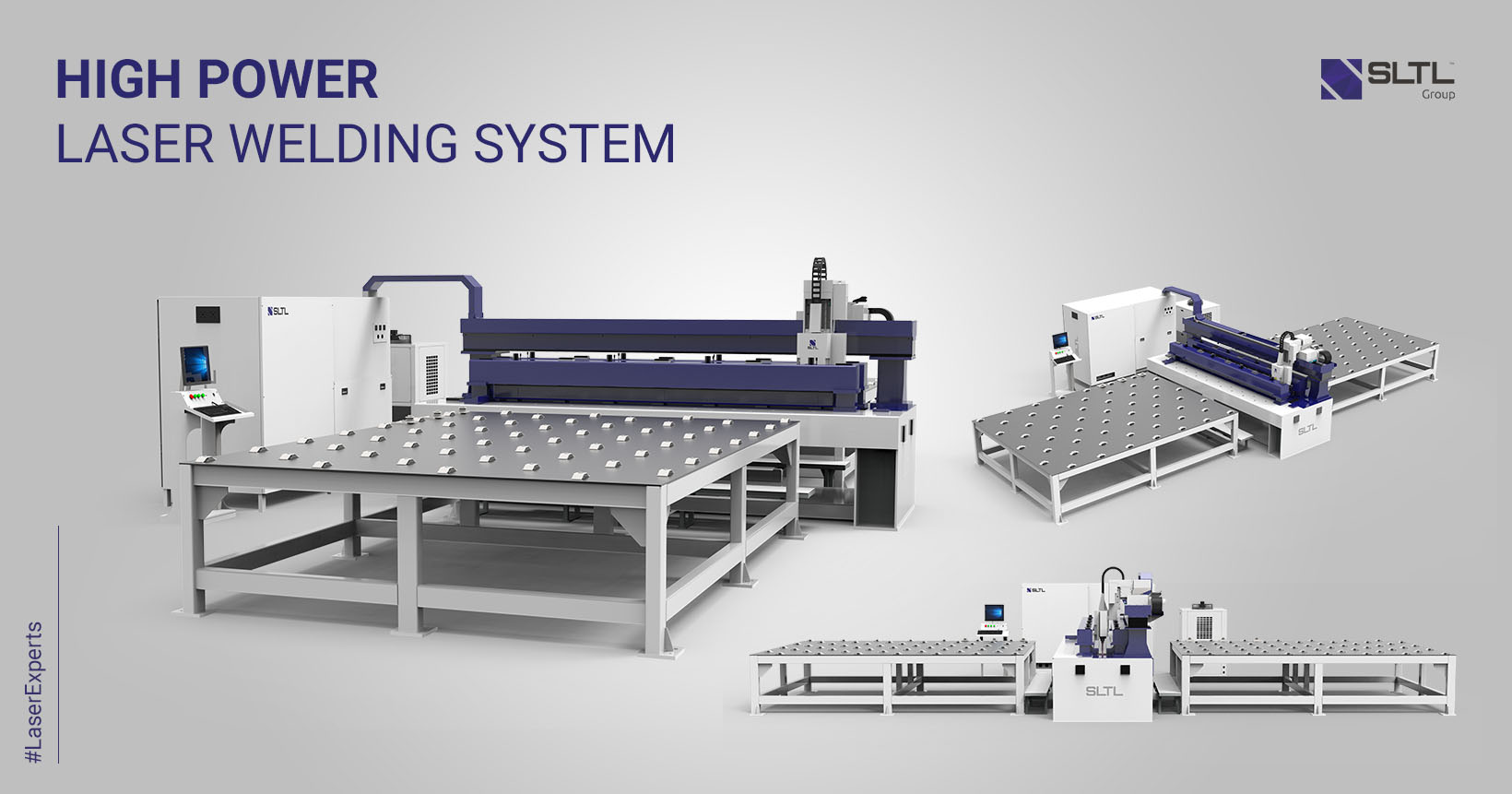

Train Bogie Laser Welding Machine

With all the experiments and the conclusions, the team at SLTL fundamentally manufactured, the first of its kind laser welding machine for train bogie. The machine supports sheet-metal with solid structure and allows fine alignment of the sheet metal to conduct welding. With handy in-built vision system, it becomes easy to spot the minor gaps (often not recognised with naked eyes) and properly align sheet metals for the welding. The laser welding operation then carried will provide continuous laser beam on the component and produces stream weld line. The operation leaves minimum footprint and provides unparalleled strength to the resultant component. With machines like this Indian Railways are flourishing with excellent quality of built.