Sawing | Crowning | Bruiting | Cone Blocking

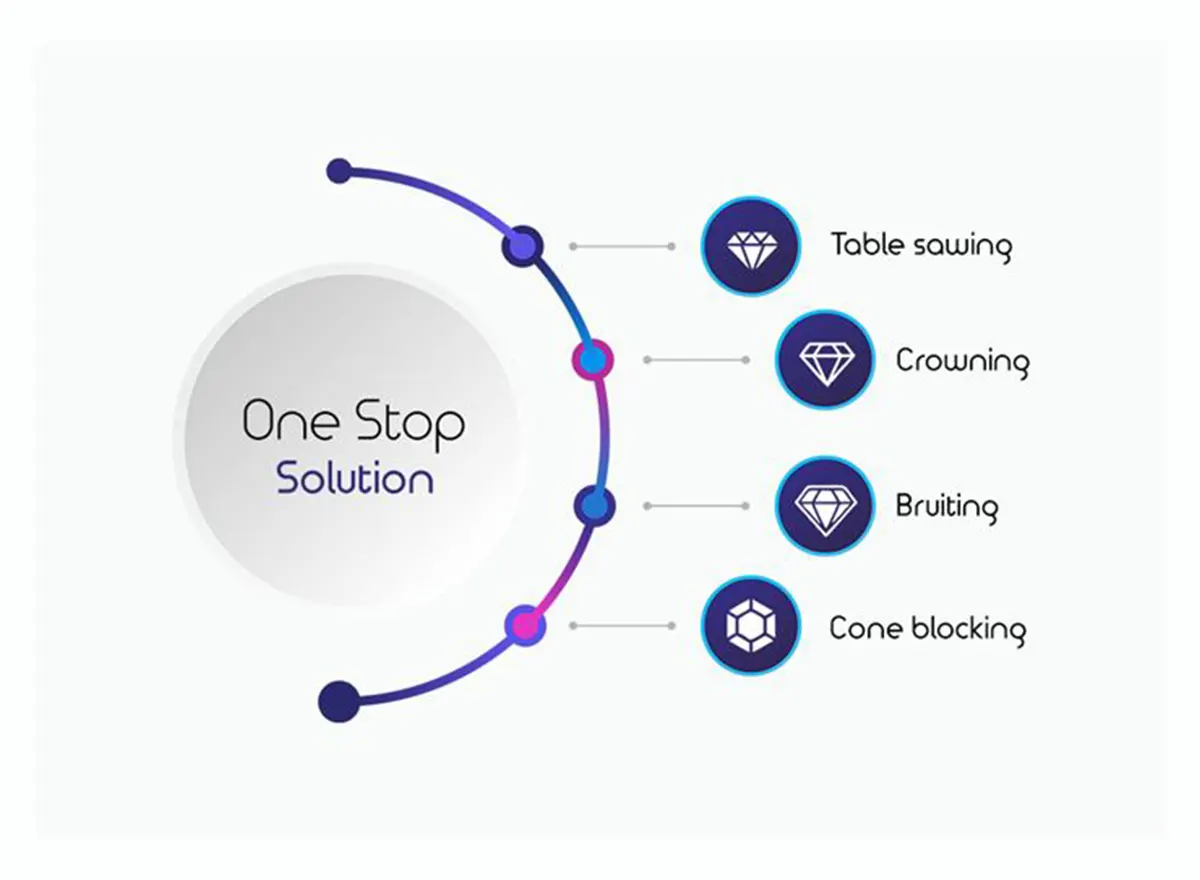

SLTL Group is the eminent manufacturer & supplier of the 4p diamond laser machine. One such development is the Hallmark 4G, a perfect blend of advanced innovation with the best practices and a must for all Diamond Manufacturers around the World. Hallmark, 4G is an all-in-one Diamond Processing System that can perform Table Sawing, Crowning, Bruiting, and Cone Blocking with the one-time fixing of the diamond rough. It is the 4th generation laser processing machine with inbuilt software for laser beam stability & robotic CNC control features.

Ever since incorporation, we have been making our own way through futuristic technology and ground-breaking innovations.

It is an all-in-one diamond processing system that is capable to perform table sawing, crowning, bruiting, and cone blocking with the single-time fixing of diamond rough.

This diamond multi-processing system performs Table sawing, Crowning, Bruiting & cone blocking, with high accuracy and speed at a marginal time without any operator’s interference in a single setup. Hallmark 4G can also be integrated with our planer machine so that even the planning process gets clubbed with the operations to minimize human errors.

Being manufactured by experts, it is a highly durable machine that can outperform multiple processes with negligible maintenance requirements. Its high-grade optics and advanced technology clubbed in a single, compact, and scratch-proof body eliminate the additional charges subsequently reducing the maintenance cost.

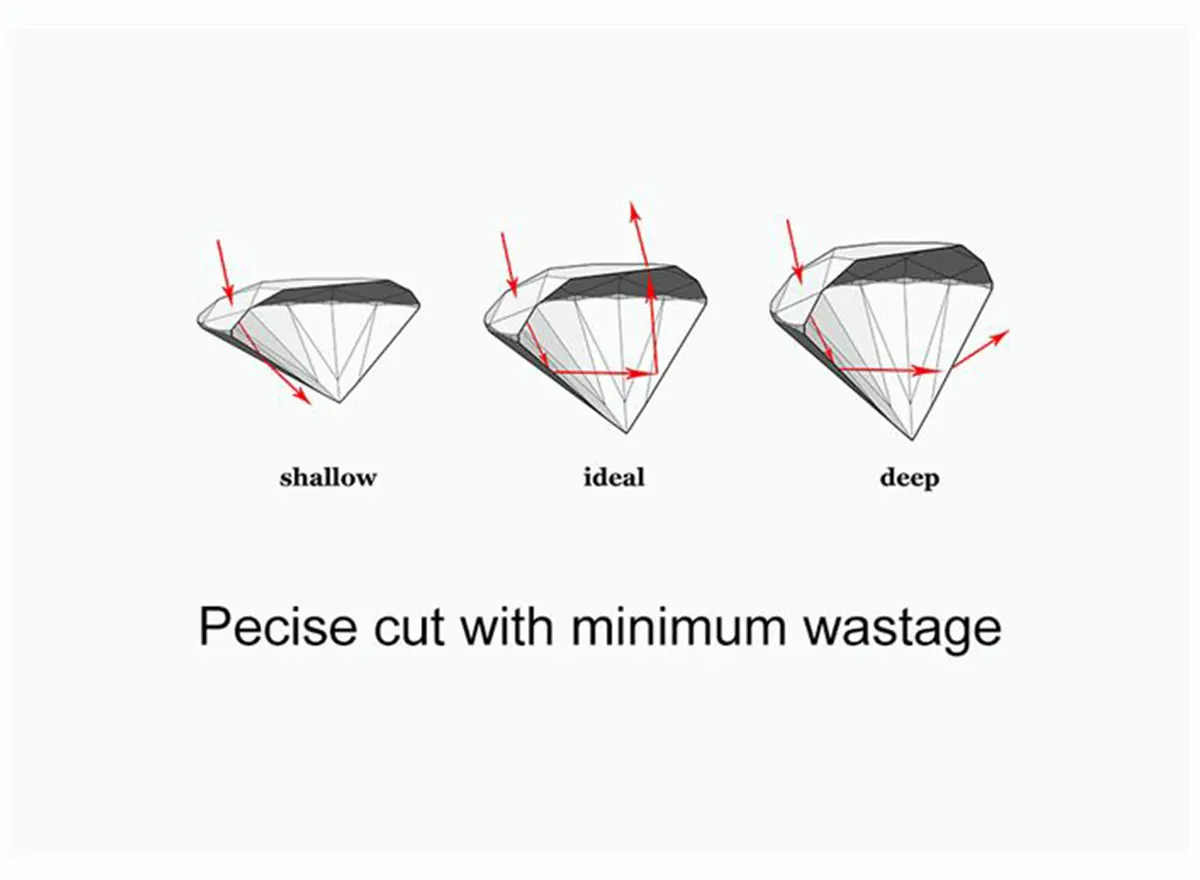

The Gain is all yours while processing the diamond rough as SLTL provides you with an almost nil breakage rate due to RTLS (Real Time Laser System). Extremely focused, stable, and accurate beam profile to achieve weight loss which provides you with fewer operation errors. In the form of Hallmark 4G; SLTL delivers an advanced processing system that ensures better quality output and reduced material wastage.

The most Progressive & easy to understand software is very straightforward. It is being designed to decrease the man-machine interaction, eventually resulting in minimized human errors. The in-house developed software not only helps in reducing the risk of damaging the stone but also automatically sets optimized laser parameters based on the size of a diamond.

Hallmark 4G is the new-generation robot for diamond processing that will help redefine laser operations in the diamond industry, with the potential to perform almost 80% of the Work. It is designed to provide you with a more systematic production cycle and error-free operations for saving a lot of processing time.

| Model | Hallmark-4g |

|---|---|

| Laser Source | SPAQ 75 W CW |

| Laser Type | DPSSL |

| Wave Length | 1064 mm |

| Beam Mode | TEM00 |

| Working Power | 4 – 18 Watt |

| CNC Table | 170 × 170 mm |

| Resolution | 1 Micron |

| Repeatability | 3 Micron |

| Accuracy | 2 Micron |

| Drive Type | AC SERVO |

| Z Axis Travel | 50 mm |

| Power Supply | 1 Phase, 15 Amp |

| Power Consumption | 1.7 KW |

| Operating Environment | |

| Temperature / Humidity | 20 – 30 °C / <60% |

| Coolant Requirement | 4 – 6 Ltr/Hr |

| Dimension | 1725 × 990 × 1610 mm |

| Computer System: Intel Dual Core | 1 GB, 160 GB HHD, 17″ LCD |

Set-up station

USA made Diode module (NG)

Interface with planner machine possibility

Power & frequency control interface with software

Interested In a Product?

Pricing, Technical Data & More

Explore our blogs for a resourceful insight into the infinite opportunities of the laser world.

The terms ‘Lab-grown’, ‘CVD’ or ‘Synthetic’ Diamonds have rung over our ears for quite some time now.

Diamond processing is the practice of changing a diamond from a rough stone into a faceted gem.

Spanning a legacy of more than 5000 years, Indian Jewellery is evident for the country’s aesthetic and the cultural history.

24*7 service support and technical assistance. You’re welcome to visit our office for other insights

E-30, Electronic Estate, G. I. D. C.,

Sector - 26, Gandhinagar - 382 028

Gujarat, India.