SLTL Group has been producing benchmark Laser Marking systems for three decades now. The Fiber and CO2 Laser Marking system are designed to give beautiful impressions on metals and non-metals with the in-house developed software system. Here, laser experts have developed CE-Compliant Low Power Laser Marking Machine; Optifly – an ON-The-Fly Automation solution; an Inspection System – for monitoring Marking. It is an excellent match for industries requiring quick production with uncompromised quality. Integrated with IoT and industry 4.0, it works on Fiber or CO2 laser technology to mark continuously on metal and non-metals. Built with sheer speed this marking machine is space-saving and can be combined with any production line.

Ever since incorporation, we have been making our own way through futuristic technology and ground-breaking innovations.

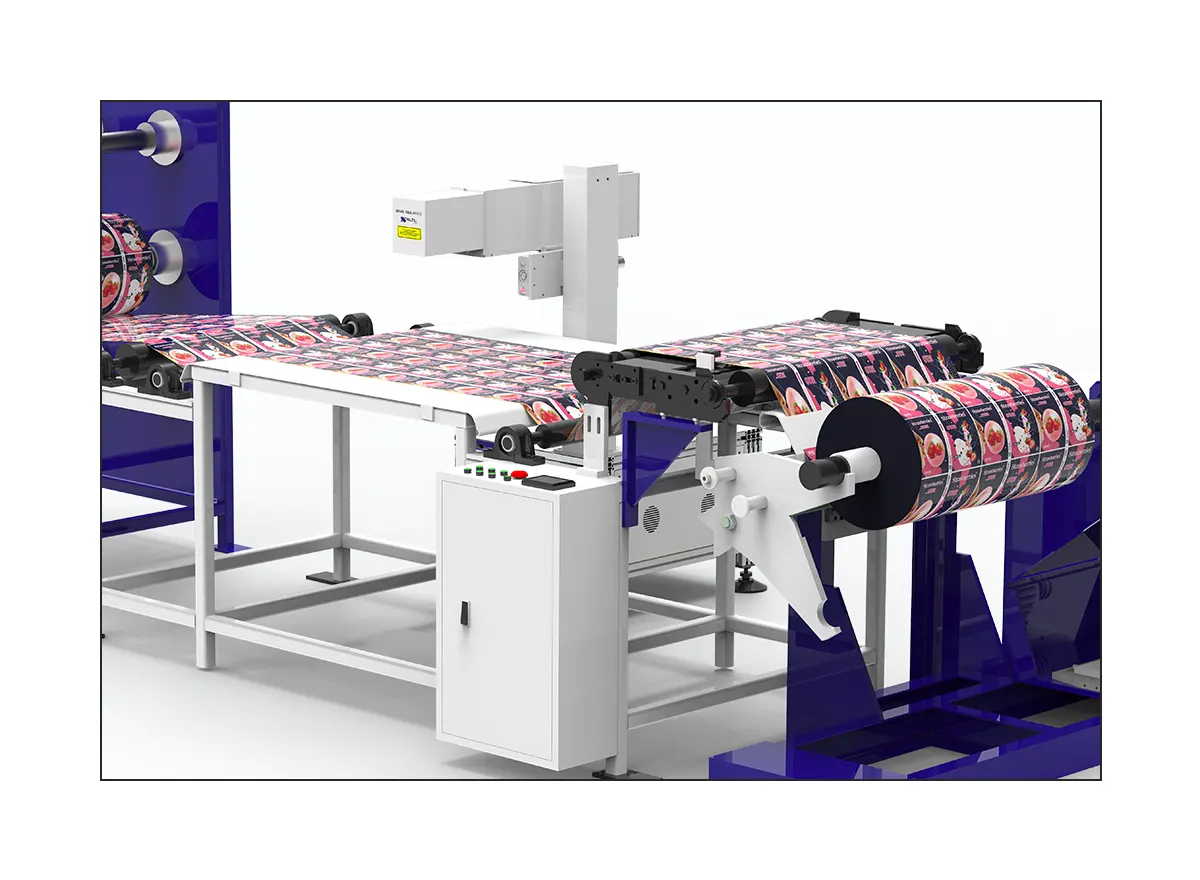

OPTIFLY is conceptualized to be integrated with any production line for reducing downtime to a negligible point and taking productivity to the pinnacle.

The customization of our laser systems provides the best compatibility and enables it to work on many things at a sheer speed with accuracy. Optifly comes with many customizable options, easy switchover possibilities, and automation which allow greater performance at high-speed continuous marking operations. Experts have designed this OTF system to mark as well as inspect the marked details in no time.

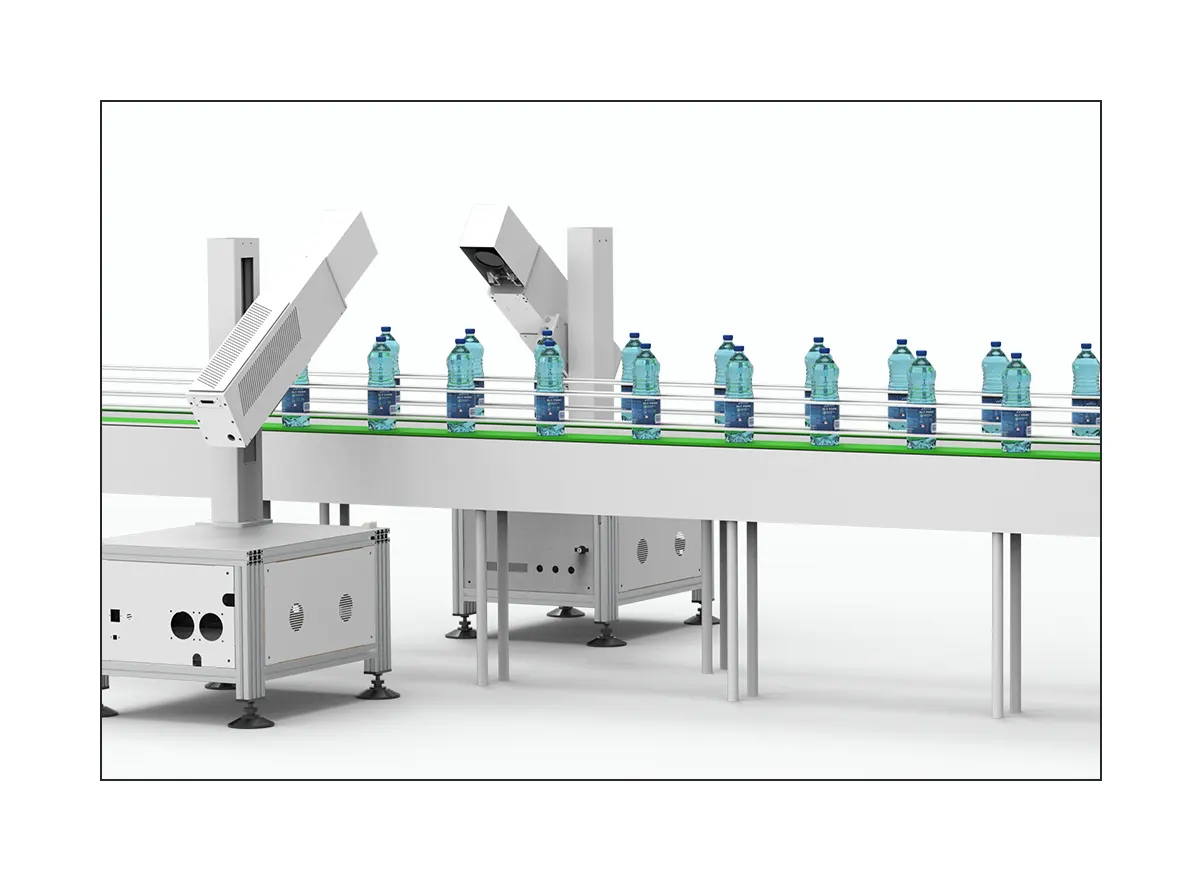

Compact mechanical design meets with multiple beam options which allow seamless & easy integration on all the applications. OPTIFLY is trusted to mark permanent error-free results at the fastest speed. This Compact yet powerful Laser marking system gets synced with any sort of production line and outperforms the consistent marking impressions at desired line speed.

A built-in camera in OPTIFLY helps not only in precise 2d scanning which allows easy tracking and tracing but also provides a platform for precise and accurate marking. This technology allows the configuration of the software and facilitates locating and altering the marking position conveniently.

OPTIFLY is integrated with a high-performance software application that extends smooth and fully automatic production flow. Its versatile application allows quick modifications in the details to be marked and can be verified as and when needed. The user-friendly software allows convenient selection options of different types of marking results and marking details be it in terms of a bar code, batch number, serial number, logo, alphanumeric texts, QR codes, and other marking options.

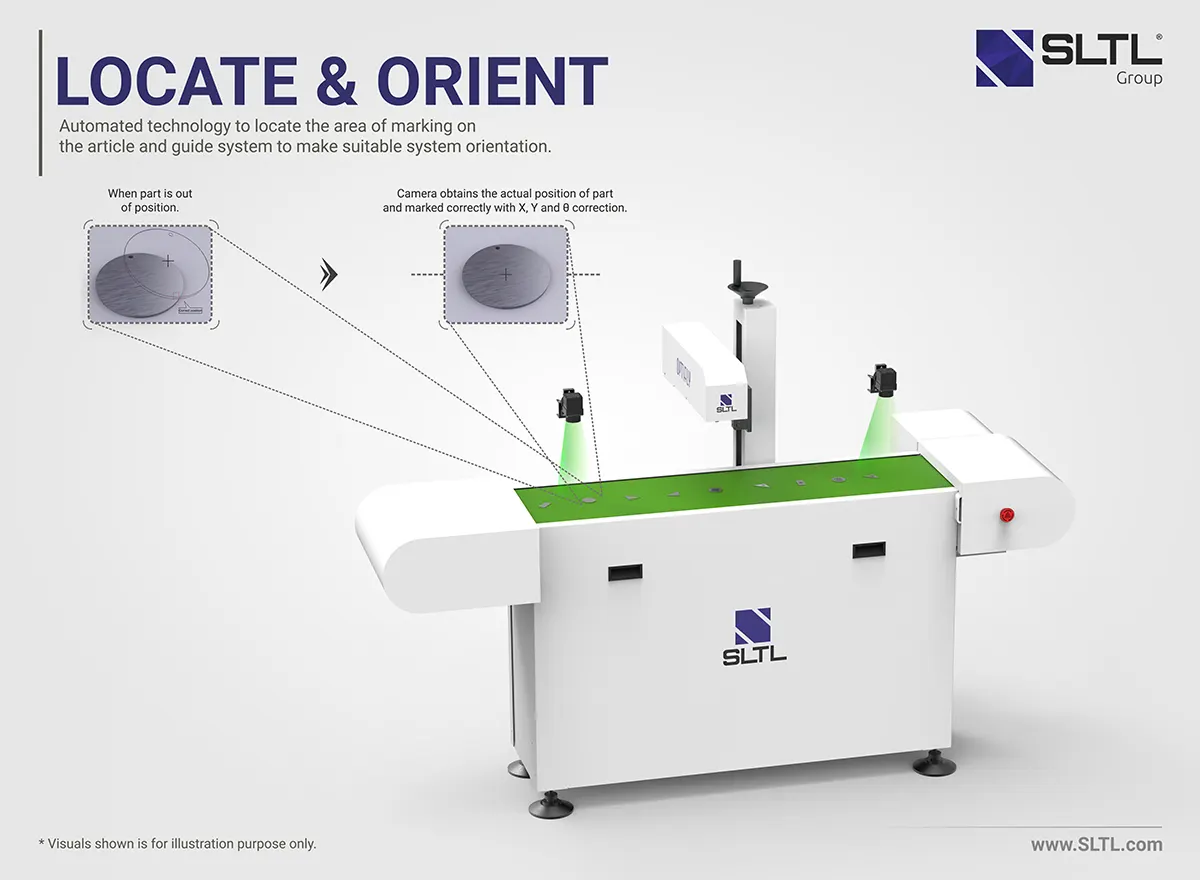

Once the objects begin moving on the conveyor, the initial process begins with “identify”, the fundamental form of the article is identified and compared with knowledge already fetched in the database.

Throughout this method, the package is already ready with parameters and signatures which will facilitate the system to find the realm of operation. ‘Locate’ is one of the necessary functions because it can permit the right position on the component to induce operation.

As per the known object and set space of marking in the previous method, the system fetches the information and suggests changes if needed. Throughout the ‘orient’ method the smart intuitive software makes adjustments to the drawing for the marking process to take place. The direct connection between the laser marker and the vision system enables the practicality of position correction because the laser marker requests the coordinates from the OPTI FLY system.

Once the article is known to its form, set the marking space supported parameters and orienting as per the appropriate position; the marking method takes place. The article is operated with an optical laser and the results area unit obtained.

The verification method is like the quality checking method done by the system itself. Throughout this method, the system with pre-compiled knowledge cross-checks the important pictures of the objects through a vision camera and verifies if the system has done the marking operation or not. The verification method is to assure that no object is incomprehensible on the road while not marking operation in alternative cases knowledge and Images of what’s being marked should be saved for traceability functions.

Once the verification method, there comes a method to assure that marking on the article is in step with pre-outlined customs and quality. This is often associated degree assurance method that makes certain the best on the lines gets through whereas eliminating the issues. The system can check the marking surface on the article through advanced vision systems and declares ‘ok’ and ‘not ok’ on the screen. That any ‘not ok’ merchandise area unit is eliminated.

SLTL’s OTF machine works on Fiber or CO2 laser technology to mark continuously on metal and non-metals. Built with sheer speed this marking machine is space-saving and can be combined with any production line. Integration into the entire system is easy due to the comprehensive interfaces.

| Laser | Sealed CO₂ |

| Laser Power | 30 W |

| Marking Area | 60 x 60 mm |

Panel A.C.

Fume suction Rotary Device

X-Y axis manual / motorized Actuator motorized Automation

Indexing table Conveyor belt Pick & place CE Compliant

Interested In a Product?

Pricing, Technical Data & More

World’s best high speed fiber laser forming machines with precise and accurate processing for all your business requirements such as metal sheet cutting, welding, cleaning, marking etc.

Ever since incorporation, we have been making our own way through futuristic technology and ground-breaking innovations.

Explore our blogs for a resourceful insight into the infinite opportunities of the laser world.

We believe in developing innovative ideas as well as smarter equipment, and Technology is what has kept us growing.

We may be fascinated by the importance of laser today as we are surrounded by things which are a by-product of laser application.

"Laser marking" stands for marking or labeling on work pieces and materials with a laser beam.

24*7 service support and technical assistance. You’re welcome to visit our office for other insights

E-30, Electronic Estate, G. I. D. C.,

Sector - 26, Gandhinagar - 382 028

Gujarat, India.