The laser machines brought a revolutionary change in the Diamond Market.

The Indian diamond market is the largest diamond market with a net worth of Rs 6000 Crores. The diamond industry contributes 7% of the total GDP and 15% of the total merchandising exports. The history and transformation of the diamond industry date back to 4th century BC.

Diamonds were discovered firstly in India and as India had an active international trade; it started enjoying the monopoly in the Diamond market till diamonds were discovered in Brazil in the 1700s. The industry received a fatal blow during the British era as international trade became restricted.

After independence, many diamond traders started purchasing rejected diamonds from the open market in Belgium. The cutting and polishing were majorly done at Surat and Navsari which soon changed the fate of Indian Diamond Industry. India had become an important centre for diamond cutting and polishing.

The whole diamond process required skilful workers and it was time- consuming that made diamonds more costly. The processing of diamonds was a gradual process. Even after such precision work of artisans, the wastage could not be avoided. The adulterants present in the diamond originally could not be identified easily, which sometimes led to the origination of poor quality diamonds.

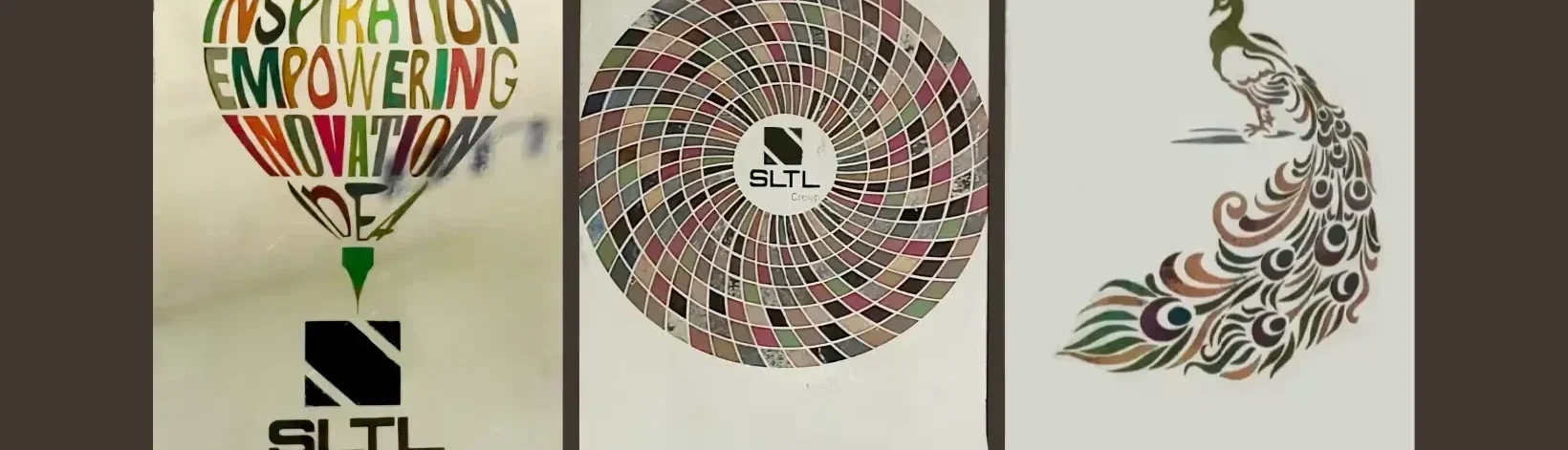

The laser machines brought a revolutionary change in the Diamond Market. The diamond machines provided all the applications starting from Planning to Polishing. These minimized the wastage as well as scanned the impurities which boosted the quality of the diamonds. India became the most important centre of diamond processing.

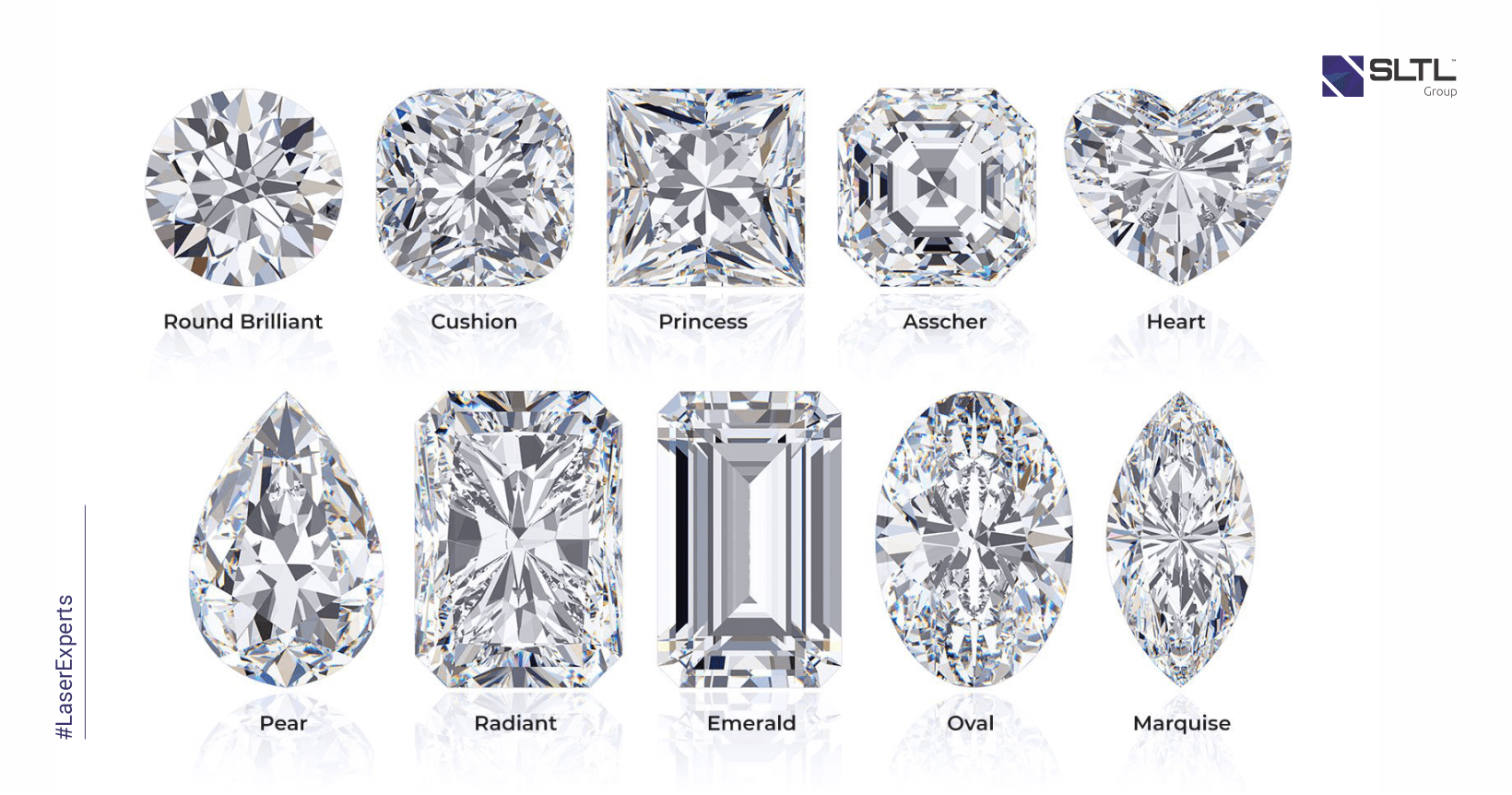

SLTL group provides a one-stop solution for diamond processing starting from planning and marking, cleaning or sawing, bruiting and polishing. The measurement of the rough diamond is done by an AI-assisted planning process. It provides much needed insight regarding the optimal yield of the diamond to the user. Specialized software enables expanding up to many complicated shapes such as Heart, pear and also customised shapes. After that, the numbers of sides of sawing and bending are selected, ensuring utmost safety. The next step is to cut the rough diamond according to the plan. The end output generated is appreciable in comparison to what we once used to get from the conventional method of diamond planning

Automated machines provided great support to the diamond industry. It has enhanced accuracy and reduced wastage. The machines are precision personified. The traditional process used to take approximately 8 months which has now dropped down to a mere 8 days with the help of AI.

Currently, 30 countries process diamonds, but India leads the chart by exporting 75% cut and polished diamonds throughout the world and it stands at US$ 23.73 Billion as of February 2019. The Indian Diamond market contributes 29% of the Global Gems and Jewellery market and is the fastest growing market throughout the world.

INDIAN DIAMOND MARKET IS AN EXEMPLARY AMALGAMATION OF NEW TECHNOLOGY AND CONVENTIONAL SKILLS.

(References: Gems and Jewellery Industry in India-IBEF-ibef.org, The Sparkling Diamond Industry of India-IIIEM-iiiem.in)