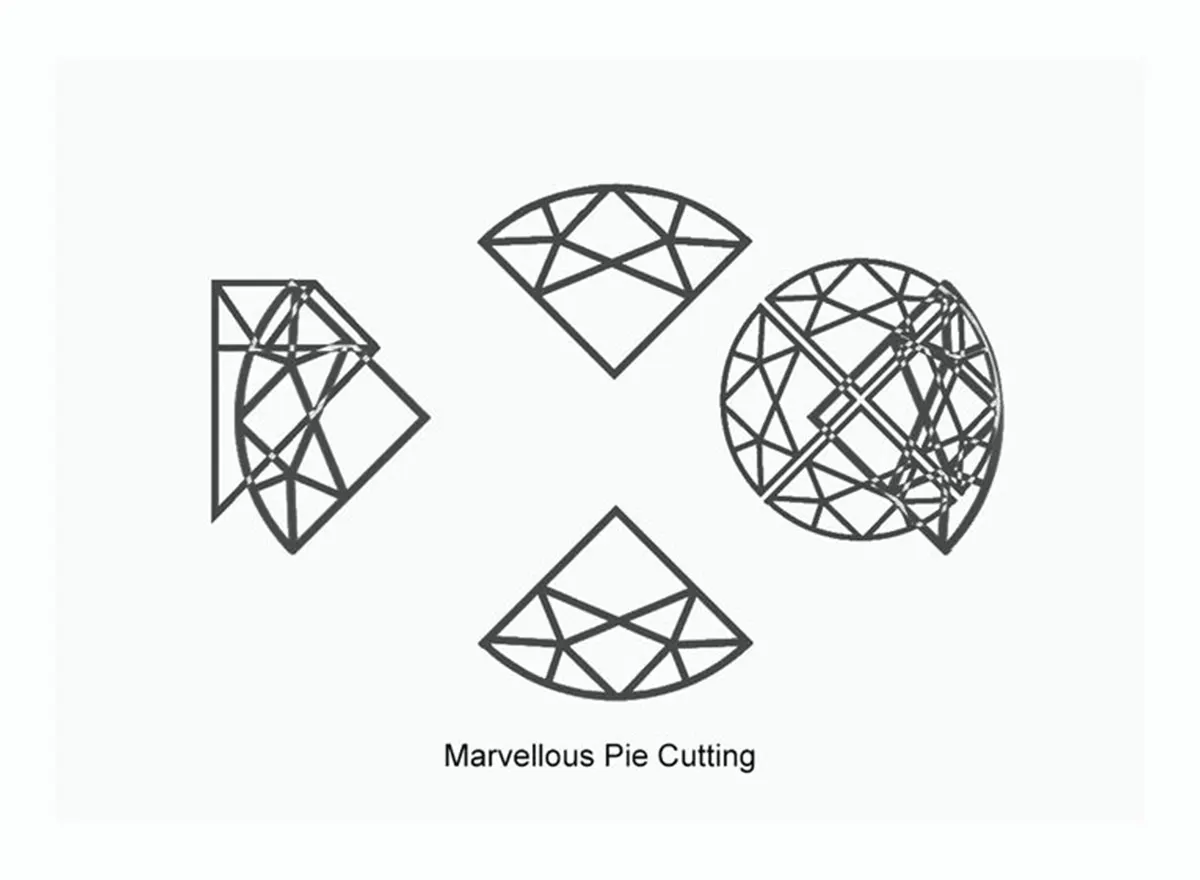

SLTL Group’s Hallmark Grenotec is the new generation of robot for diamond processing which will help redefine laser operations in the diamond industry, with the potential to produce almost 80% of the work. The diamond is in total protection with the latest 3D laser fire protection system and power frequency control interface with the software. It also has a high-speed laser focus facility on uneven surfaces. This system comes with an Angle and Pie sawing option. Hallmark Grenotec is environment-friendly with short & straight weave lengths. Its different diamond fixtures and innovative software help in precise diamond pie sawing.

Ever since incorporation, we have been making our own way through futuristic technology and ground-breaking innovations.

A laser diamond cutting machine with high-speed laser focus that results in a systematic production cycle and error-free operations.

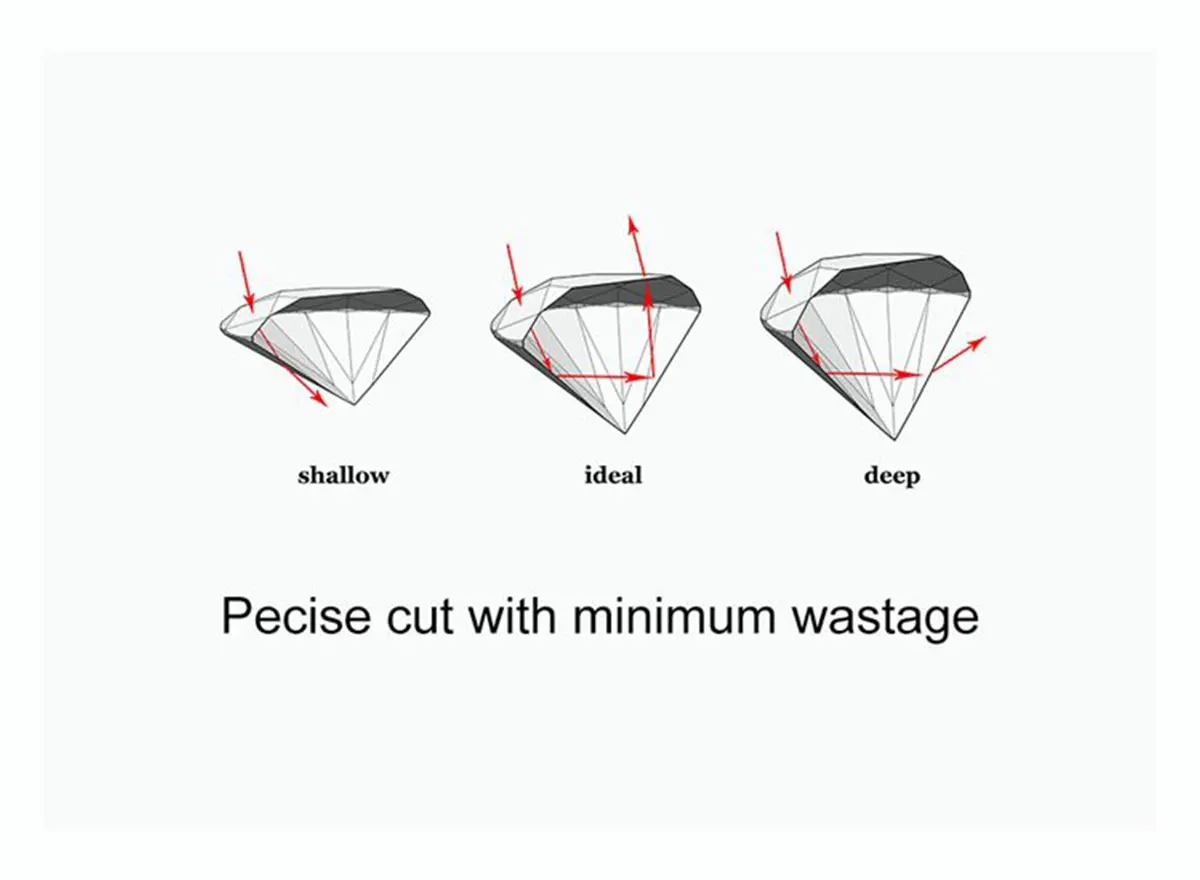

The Grenotec is designed in such a way that it rapidly cuts diamonds at the maximum possible watts resulting in greater output in less time. More importantly, this rapid speed is achieved while ensuring minimum breakage because of the highest precision and accurate results.

It offers the advantages of minimal weight loss, minimal risk of damage to your diamonds, easy maintenance, high durability and many optional add-ons including pie-cut sawing, and shaping. The Grenotec utilises a high-end green laser that has proven to be best efficient in sawing high-tension stones whilst maintaining near-zero breakage rates. This technology is best for complex Production in less time.

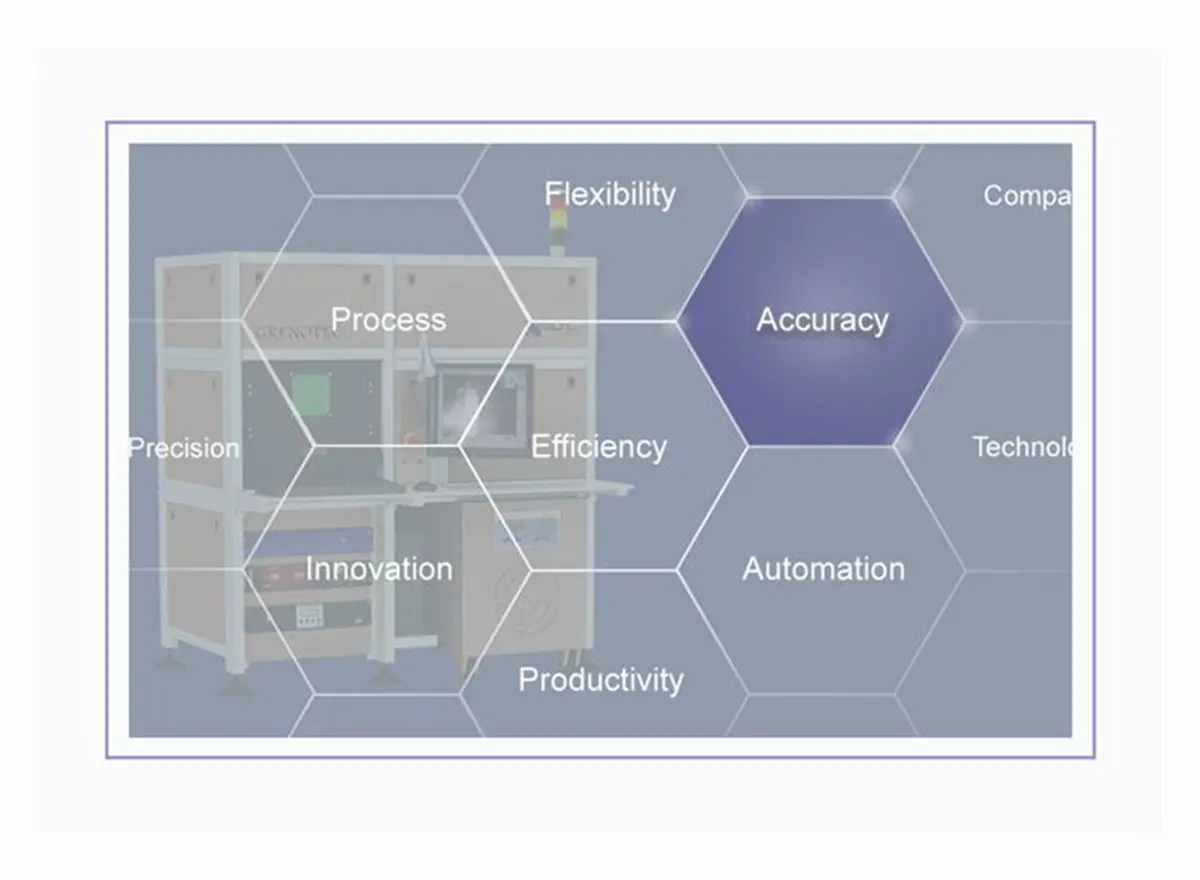

Grenotec does totally unmanned, in-detail pie cutting within unbelievable seconds of time span. Even with high speed, it achieves the highest level of productivity and optimum safety in the diamond pie-cutting/bending process.

An entire stone-setting process and crucial bending process are performed by a highly advanced, intelligent and quick-working Grenotec. The smart system provides 100% accuracy in pie-cutting performance and hence gives a more polished gain. It has the ability to fix multiple diamonds in the cassette which facilitates faster production from the machine. This provides you with a more systematic production cycle with error-free operations.

Laser-induced micro-cracking for impurity remover as well as diamond protection. The in-house developed software provides a framework which helps in reducing diamond wastage and thereby increases efficiency. Integrated with smart technology, diamond processing has now become more convenient now.

| Model | Grenotec |

|---|---|

| Wave Length | 532 nm |

| Beam Mode | TEM00 |

| Working Power | 8 – 15 Watt |

| CNC Table | 180 × 180 mm |

| Resolution | 17 Micron |

| Repeatability | < 10 Micron |

| Accuracy | < 10 Micron |

| Drive Type | AC SERVO |

| Z Axis Travel | 50 mm |

| Power Supply | 1 Phase, 30 Amp |

| Power Consumption | 1.7 KW |

| Dimension | 1400 × 975 × 1700 mm |

| Computer System | Intel® Core™ i3 based CPU or higher |

Interested In a Product?

Pricing, Technical Data & More

Explore our blogs for a resourceful insight into the infinite opportunities of the laser world.

Diamond processing is the practice of changing a diamond from a rough stone into a faceted gem.

Spanning a legacy of more than 5000 years, Indian Jewellery is evident for the country’s aesthetic and the cultural history.

The terms ‘Lab-grown’, ‘CVD’ or ‘Synthetic’ Diamonds have rung over our ears for quite some time now.

24*7 service support and technical assistance. You’re welcome to visit our office for other insights

E-30, Electronic Estate, G. I. D. C.,

Sector - 26, Gandhinagar - 382 028

Gujarat, India.