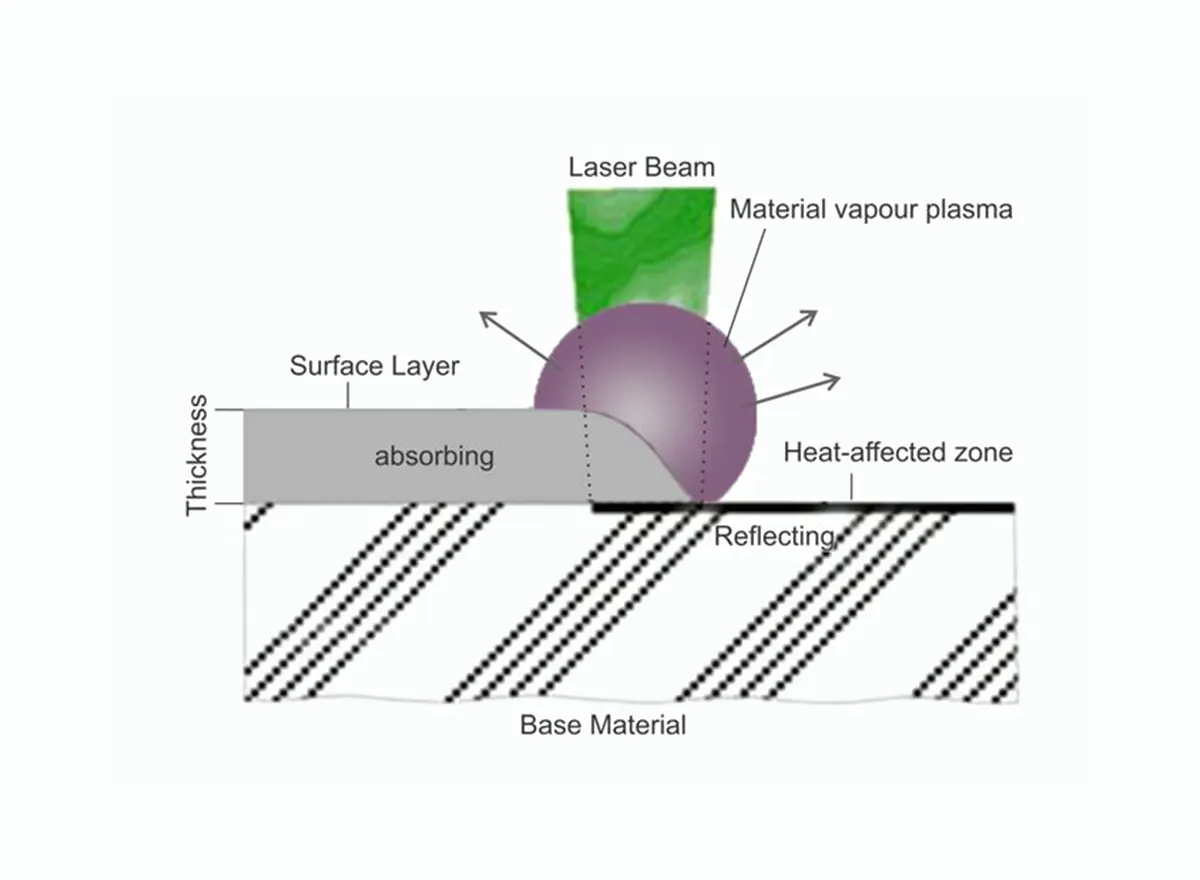

SLTL Group has introduced the Fiber Laser Cleaning System to attain the application with utmost precision and efficiency as Surface cleaning is one of the key applications in the industry these days. The system is used for the surface coating and contamination removal process. This futuristic laser cleaning solution can capably remove rust, oil, paint, grease, colour and other particles from the surface of the metals. These smart machines are used in almost all industries these days and we have also provided one such solution for cleaning naval ships to clean rust from the surface, cleaning oil tanks and for removing paint coating of the ship.

Ever since incorporation, we have been making our own way through futuristic technology and ground-breaking innovations.

It removes surface contamination and material coatings like rust, oil, paint, grease, colour and others.

[devvn_ihotspot id=”6398″]

The machine has a control system that allows the operator to adjust the laser power, pulse duration, and scanning speed while performing the operation. The smart system enables easy processing and effective cleaning of the parts to achieve desired results.

The laser Cleaning System is a handheld device that allows it to operate on large and complex material surfaces with ease. The ultra-portable machine comes in handy when the area is not defined and it is built to outperform the cleaning of contamination throughout the components. It also allows for the removal of contaminants from hard-to-reach areas, such as the underside of a component.

The power output of laser cleaning machines can vary from low power to high power, which allows for the efficient removal of thick layers of contaminants from surfaces. The appropriate power level can be selected based on the level of contamination and the type of material being cleaned, ensuring effective cleaning results.

Laser Cleaning Systems comes with easy to use control panel allowing users to make necessary variations without hustling with the complexities of software. Not just this, but this robust system flexibly cleans the components of varied shapes and sizes.

The robust Laser cleaning solution is compatible to perform various operations like; cleaning rust, oil, paint, grease, cleaning tires, electronics, mold cleaning and much more. SLTL’s Laser cleaning machine offers a complete solution to clean material deformation and contaminations in a sustainable way.

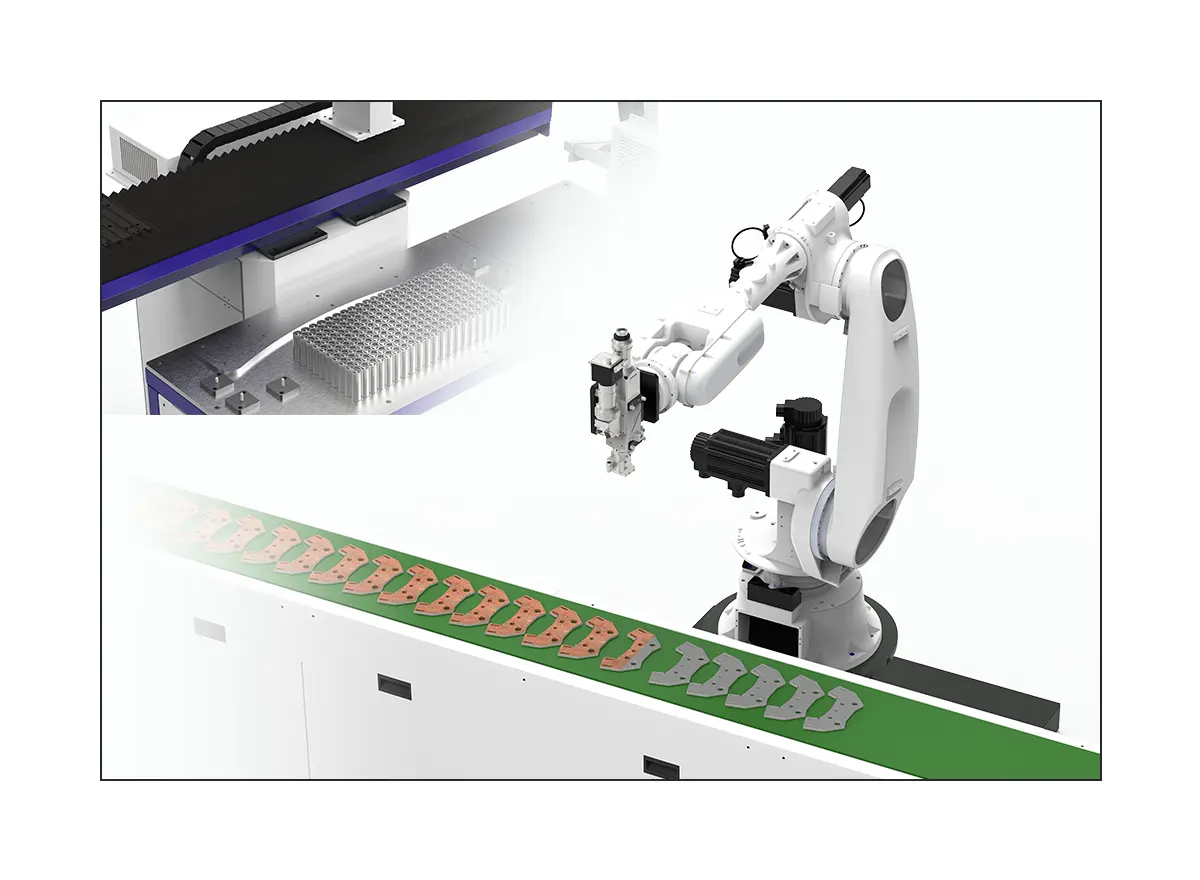

One of the key features of SLTL’s laser cleaning system is its ease of integration with automation. This allows the system to be seamlessly integrated with a wide range of automation systems, such as existing conveyor lines and indexing systems, to meet the specific needs of the application. Overall, the easy integration with automation allows for a more efficient and streamlined cleaning process for the system to be easily incorporated into a larger production line for maximum efficiency and precision.

[table id=”35″ /]

*TECHNICAL SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE

Interested In a Product?

Pricing, Technical Data & More

World’s best high-speed laser machines with precise and accurate processing for all your business requirements such as Laser cutting, welding, cleaning, marking and others.

Ever since incorporation, we have been making our own way through futuristic technology and ground-breaking innovations.

Explore our blogs for a resourceful insight into the infinite opportunities of the laser world.

SLTL Group is the company that has defined what is called a "Trailblazer".

The new era of technology is driven by innovative engineering solutions

Laser technology is revolutionizing and making the automotive sector more sustainable.

24*7 service support and technical assistance. You’re welcome to visit our office for other insights

E-30, Electronic Estate, G. I. D. C.,

Sector - 26, Gandhinagar - 382 028

Gujarat, India.