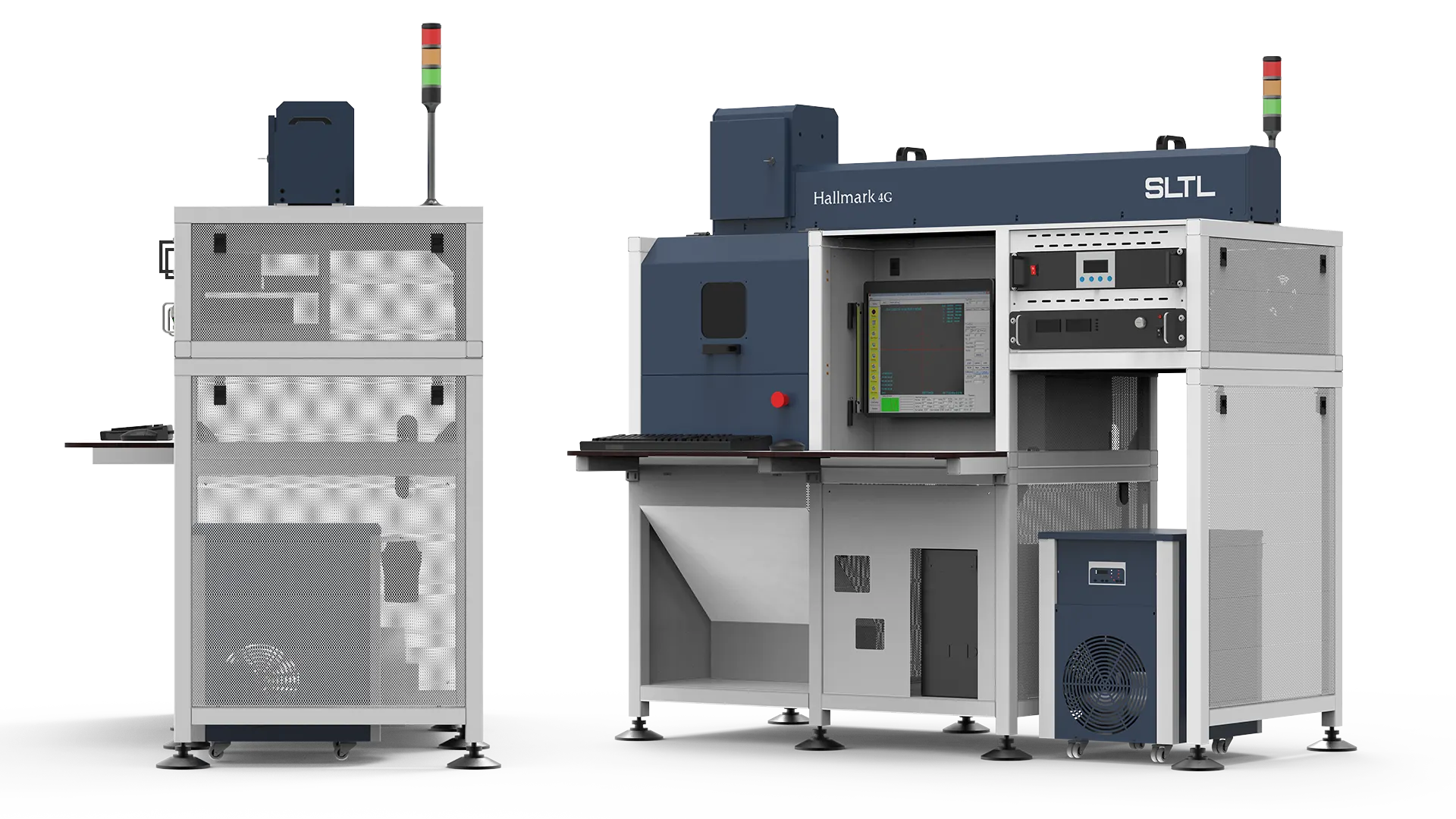

Hallmark 4G

SLTL’s Laser machines are bifurcated for the finest quality and precision to minimum weight loss while creating aesthetic diamonds in desired shape and size elegantly. From the cutting of table, crown, bruit, cone, diamond girdle and much more to create the diamonds at the same time, giving the feasibility of flexibility to process different shapes and sizes of the diamonds in just a single click. Giving a multi-dimensional advantage of an all-in-one machine, the Diamond Multi-Processing System performs excellent functions to transform rough into a perfectly edged diamond.

Manual processing of diamonds by skilled workers was costly and required almost 8 months to create one diamond. Not just this, the manual process involved immense wastage of the gemstone while processing.

We have always brought in needed innovation through technology to sustain the diamond industry. The advanced technology can process multiple diamonds at a time and has reduced the working time from months to a few days and diamond wastage is nullified.

Interested In a Product?

Pricing, Technical Data & More

Testimonials

Explore our blogs for a resourceful insight into the infinite opportunities of the laser world.

Spanning a legacy of more than 5000 years, Indian Jewellery is evident for the country’s aesthetic and the cultural history.

Diamond processing is the practice of changing a diamond from a rough stone into a faceted gem.

The terms ‘Lab-grown’, ‘CVD’ or ‘Synthetic’ Diamonds have rung over our ears for quite some time now.

24*7 service support and technical assistance. You’re welcome to visit our office for other insights

E-30, Electronic Estate, G. I. D. C.,

Sector - 26, Gandhinagar - 382 028

Gujarat, India.