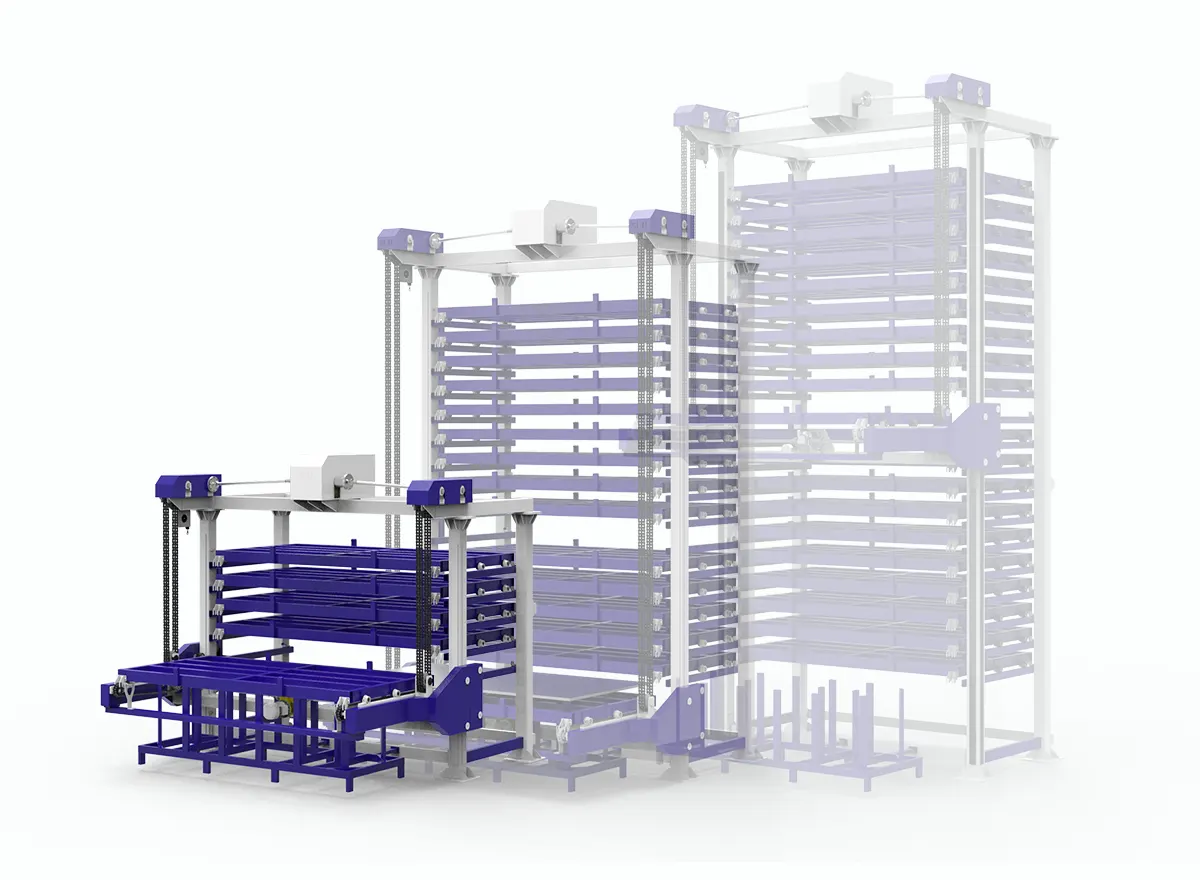

Opti – Store is an automated sheet metal storage system designed to securely exploit high roofs while executing a goods-to-operator in work process. By investing in Opti – Store, you can reduce your storage capacity impression by joining multiple sheet metal racks into a single tower that feeds your handling machines directly. Customized stocking options such as 10, 15, 20 floors make it really compatible regardless of the manufacturing facility, at huge warehouses and factories, it demonstrates remarkable space management. A sophisticated space management leads to the streamlined process and inventory management and ultimately saves humongous region cost. Elevator with double connected chain permits solid holds over the sheets while transportation.

Ever since incorporation, we have been making our own way through futuristic technology and ground-breaking innovations.

Opti-Store is an automated sheet metal storage system developed to safely exploit high rooftops while carrying out a goods-to-operator in work process. Workplace Safety, Efficient Material Storage and Flow, and Storage Footprint Reduction are all benefits of the optic sheet stacker.

Opti – Store assist you with utilizing most extreme space in your processing plant since it involves little space, it empowers floor space reserve savings of up to 80%. Space-saving storage of auxiliary pallets with storage cassettes Multiple-machine connection. With Opti – Store you can decrease your capacity footprint by consolidating numerous sheet metal racks into a single tower.

With Opti – Store you can store sheets up to 245 tons in huge format. This storage system comes up in three diverse models, with 10, 15 and 20 no. of palates, giving you loads of capacity with the goal that you can store every one of your sheets at one place.

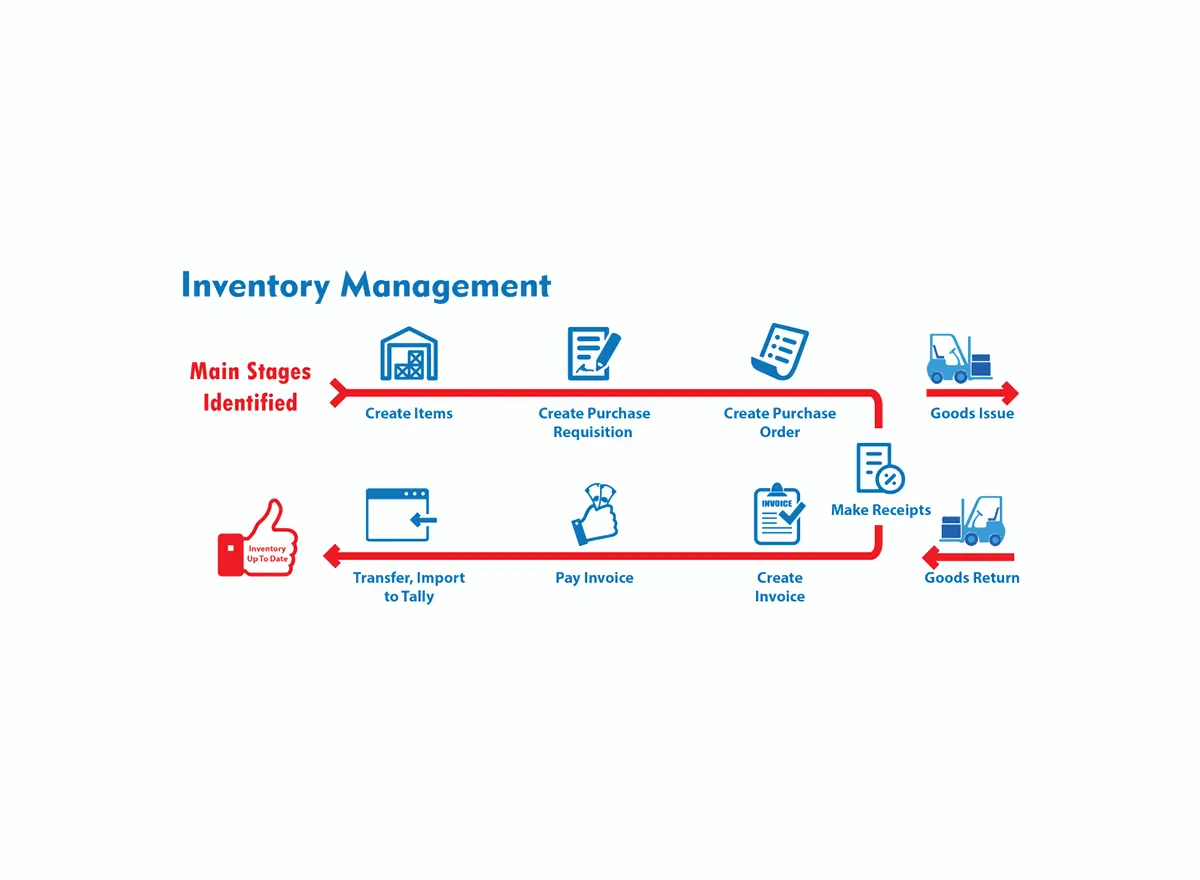

It enables you to store information about sheets stored in the Opti – Store. It store information in form of no. of sheets, sheet size , thickness, material etc. It keeps track on product movement, leading to overall efficiency in business. Whether it’s for manual stores, automatic unprocessed-material storage systems, or large-scale storage systems, the Opti Storage module enables you to control the entire material flow of your production and manage your inventories.

On the off chance that your sheets are spread over the floor in your industrial facility, initially it will possess bunches of room in your processing plant and besides it might make harms your products and it might likewise cause accidents at your work place. You can connect multiple machines to the Opti as required, either directly or indirectly. So with Opti – Store you can put all your products at one place so it may not make any harm your goods and avoid work accidents too. The reliable and efficient Opti store compact store makes material handling easier for you. No goods damage, no work accidents.

Through Opti storage you will find time reduction as well as increasing of material flow. The Opti storage can be integrated seamlessly into your automated sheet metal production. With this storage solution you can have record of everything which is there in the storage as this storage system records all the information about the goods in terms of no. of sheet, material type, size, thickness etc. helping you to reduce time of handling the goods and increase material flow.

Reduces the cost of storage handling. Opti – Store is a onetime investment and life time advantage of solution to your work place. With this storage system you don’t have to spend additional money on material handling as Opti – Store is an ultimate solution as far sheet storage is concern.

The extensive range of Opti software supports you throughout the entire production process. Control your operational work process in a simple and targeted manner, from managing your customer orders and purchasing processes to delivery of the produced parts. The software enables communication between the storage system and machine. Through the direct coupling with the machine control, you can keep a constant eye on the status of your orders. The machine acknowledges the information from you and monitors sheets stored in it. The machine records information as far as thickness of sheets and material.

| Manual | ||

|---|---|---|

| No of pallet | Nos | 5 |

| Pallet size | mm | 3100 x 1598 |

| Max weight carrying capacity per pallet | Kgs | 2000 |

| Sheet size per pallet | mm | 3000 x 1500/2500 x 1250 |

| Max height per pallet | mm | 100 |

| System height | mm | 3100 |

| Automatic | ||

|---|---|---|

| No of pallet | Nos | 10 |

| Pallet size | mm | 3100 x 1598 |

| Linear Lifting speed | mpm | 5.5 |

| Max weight carrying capacity per pallet | Kgs | 3000 |

| Sheet size per pallet | mm | 3000 x 1500/2500 x 1250 |

| Max height per pallet | mm | 125 |

| System height | mm | 4400 |

| Automatic | ||

|---|---|---|

| No of pallet | Nos | 15 |

| Pallet size | mm | 3100 x 1598 |

| Linear Lifting speed | mpm | 3- 5 |

| Max weight carrying capacity per pallet | Kgs | 3000 |

| Sheet size per pallet | mm | 3000 x 1500/2500 x 1250 |

| Max height per pallet | mm | 125 |

| System height | mm | 5600 |

| Automatic | ||

|---|---|---|

| No of pallet | Nos | 20 |

| Pallet size | mm | 3100 x 1598 |

| Linear Lifting speed | mpm | 3- 5 |

| Max weight carrying capacity per pallet | Kgs | 3000 |

| Sheet size per pallet | mm | 3000 x 1500/2500 x 1250 |

| Max height per pallet | mm | 125 |

| System height | mm | 6100 |

Interested In a Product?

Pricing, Technical Data & More

Explore our blogs for a resourceful insight into the infinite opportunities of the laser world.

We've got the vision to deliver continuous innovation, working in the future.

Have you ever pondered about the laser technology that everybody seems to be talking about? Actually, you would be surprised to know that Laser is just an acronym for Light Amplification by Stimulated Emission of Radiation.

The new era of technology is driven by innovative engineering solutions

24*7 service support and technical assistance. You’re welcome to visit our office for other insights

E-30, Electronic Estate, G. I. D. C.,

Sector - 26, Gandhinagar - 382 028

Gujarat, India.