Are you looking for the newest cutting-edge technology in the market for cutting metal sheets? Then you are at the correct place where ultra-high power fiber laser cutting machines are the answer.

The cutting market has quickly embraced ultra-high power (UHP) fiber lasers in recent years, with powers having different ranges. It is anticipated that the maximum laser power for cutting applications will continue to rise.

Ultra-high power fiber laser cutting machines have the capability to accomplish thick plate cutting quickly and with excellent quality. These lasers also have a number of advantages over other cutting techniques.

This ultra-high power laser machines have significance in many different kinds of industries. All the industries, from automotive, appliances, electronics, to energy, no one lacks in using sheet metals. No matter what you look at, you will realize that sheet metal is the most important part of almost all the products that we use in our day to day life.

One of the most developing industry is Sheet metal fabrication in which it involves cutting, welding, and assembling metal sheets.

This is considered as a multi-stage process where there is a necessity of advanced technology and machine driven expertise in order to handle the growing workload of the industry.

Based on the kind of requirement, various kinds of machines are used in order to carry out the task.

Here we will showcase the importance of ultra-high power fiber laser cutting machines in many different industries.

Applications of Ultra-High Power Fiber Laser Cutting Machines in Sheet Metal Fabrication

Several applications await your exploration, listed below:

Automotive Industry.

Ultra High Power laser cutting machines have a wide range of applications in the automotive industry. A variety of metal components for automobiles are cut with the help of ultra-high power laser cutting machines. In the automotive industry, the kind of material to be cut, the volume of production, and the required degree of accuracy and precision are some of the factors that affect the choice of laser cutter to be used.

Aerospace Industry

The fact that the laser welding and fiber laser cutting equipment are frequently utilized in the modern aerospace industry and greatly facilitate production and manufacturing is all that is necessary to realize. In actuality, laser cutting machines are also widely used in the aerospace industry, particularly in the modern aerospace industry.

This thermodynamic machine is extremely precise and sophisticated, and it is the most advanced of aerospace engines today. Every product of the aerospace industry that is manufactured is extremely complex and requires a variety of materials. High-temperature internal components are designed to withstand both extreme heat and high temperatures. The aircraft’s complete loss can be directly be the reason of the high air pressure and even the smallest error.

In addition to having a unique shape, the turbine blade’s interior has a high temperature tolerance. When advanced manufacturing techniques are applied, the system becomes complex and it can be challenging to meet procedure specifications. One example of this is when the newest high-tech techniques are used, such as laser cutting technology.

The use of industrial laser technology in the aerospace sector has expanded due to advancements in current laser technology, ongoing technological maturation, and the expansion of related industries. Laser cutting technology is a widely used technical method for laser applications in the aerospace industry.

Laser cutting is used in many areas of aero engine development, from exhaust nozzles to the intake of modern aero engines, because of its high precision, quick processing times, low thermal impact, and lack of mechanical effects. Many difficult problems have been resolved by current laser cutting technology, including processing of special surface parts, which is highly encouraged by current aeronautical vehicles, high-efficiency machining of large, thin-walled group-hole sections, high-precision cutting of part-leaf holes, and cutting difficult-to-process aero-engine components. Developments in the areas of high efficiency, low cost, short cycle, light weight, long life, and so forth have given the aviation sector a significant boost.

Construction Industry

Construction has found immense value in the application of laser technology. The laser cutting machines are being used by contractors for a variety of business projects. A laser cutter is very useful when working with plates of a particular thickness. The cutting apparatus guarantees the proper diameter size. With our laser cutters, labor productivity will increase. Moreover, the laser cutting machine produces an accurate result.

Second, sheet metal components are very helpful in the building sector. Since there are numerous work pieces with irregular shapes, the laser cutter is the best option. Our state-of-the-art machinery is very effective at shaping metal sheets into the correct shapes. You can also use our laser cutter to make samples of various work pieces.

Laser cutting machines are able to process because the heat generated is concentrated during the material cutting process.

Ship building Industry

The ship building industry has seen a rapid development in laser cutting technology in recent years. The primary material used in shipbuilding is steel sheets, and laser cutting can significantly reduce production time and costs by replacing some die cutting techniques that require complicated large molds.

Laser cutting offers many benefits over other techniques. Processing quality varies because trimming margin is manually performed and assembly space is ensured when unloading rib sheets using plasma. The ultra-high fiber laser cutting machine’s cut quality relies on metal attributes, surface properties, and operational conditions. Thicker metals may show lower-edge striation. The high-power laser source excels in cutting Mild Steel, Stainless Steel, Aluminium, Brass, Copper, and Galvanized Iron with specified assist gases.

Which metals can be cut with the help of fiber laser cutting machine?

Thanks to technological advancements, construction companies can now work with any kind of metal using laser cutters. For example, you can cut different thicknesses of steel. Both big and small batches are handled by the machine. Additionally, the laser cutters are made to handle intricate parts.

Materials that are controlled by laser cutting machines range in varying thicknesses. The mild steel and stainless steel required to build buildings are primarily used in the construction industry. However, non-ferrous metals like copper, brass, and aluminum can also be expertly cut with fiber laser cutters.

Why to choose Fiber Laser Cutting Machines?

Fiber laser cutting machines are like super-precise tools for cutting metal, and they’re becoming really popular. These machines are great because they have a special area where they do all the cutting, and the best part is, you can move the laser around easily to cut exactly where you need it. So, even if you’re dealing with a really complicated shape or part, the machine can handle it like a pro.

And here’s the cool part – these machines are like the ultimate workers because they’re super automated. This means they can do their job really efficiently, making sure you get the most amount of work done in the least amount of time with accurate precision.

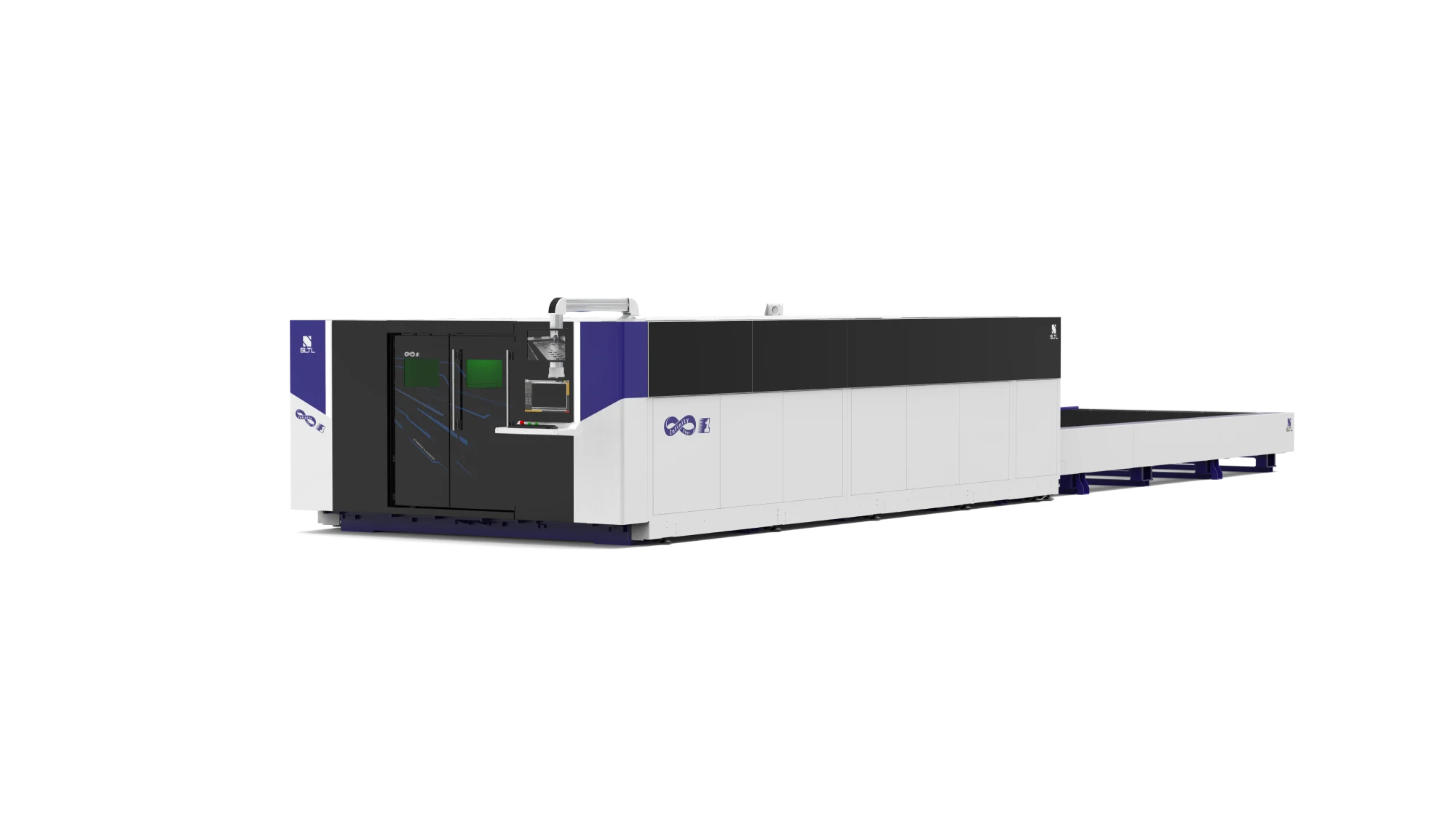

Ultra High Power Laser Cutting Machine – Infinity F1

Power: 12 kW to 30 kW

Material: Mild steel, Stainless steel, Aluminum, Brass, Copper, Galvanized Iron, Coated Sheet, Others

Conclusion

In conclusion, the arrival of ultra-high power laser cutting machines marks a transformative leap in various industries, particularly manufacturing, shipbuilding, aerospace, and automotive sectors. The remarkable capabilities of these cutting-edge fiber laser machines, characterized by their exceptionally high power, enable swift and precise metal cutting across a wide range of materials. This technological advancement not only enhances efficiency and productivity but also opens up new possibilities for intricate designs and complex manufacturing processes.

As these machines continue to redefine the standards of precision and speed in metal cutting, their impact on industrial applications is poised to be substantial, driving innovation and pushing the boundaries of what is achievable in the world of fabrication and manufacturing.