Manjit Patel

Owner, Safal Industries

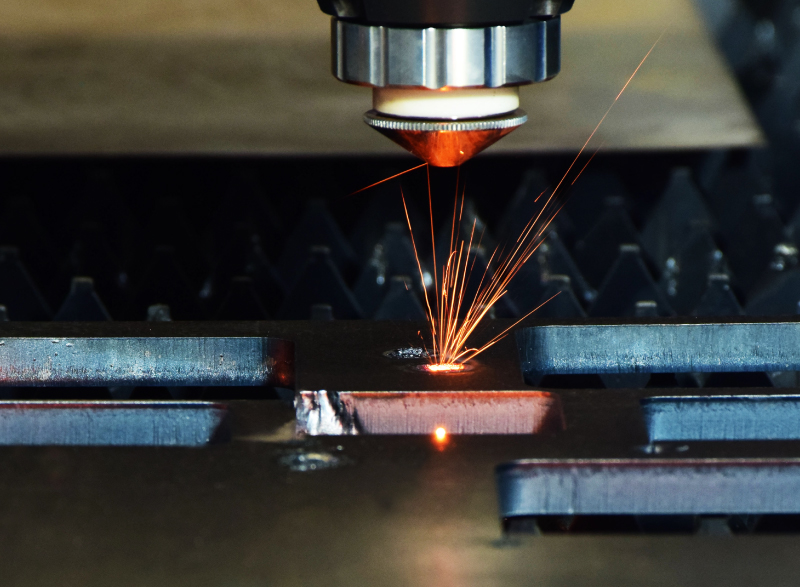

The innovation is in the foundation of the Group, as just after its establishment, SLTL invented the world’s First Fiber Laser Cutting system. A machine, which went on to become the game changer for the metal forming industry. Eventually, we emerged as the company that accounted for the laser revolution across the globe. It’s perfect for cutting a wide range of materials with precision, even highly reflective metals. Mild steel, stainless steel, aluminium, brass, copper, Inconel, speciality alloys, as well as coated and textured metal sheets, may all be cut spectacularly with this futuristic laser cutting machine.

SLTL introduced a new way to process Laser Cutting on tubes with SLTL’s Tube Cutting Series and probable automation of Bevel Cutting, Tube Slitting and Automatic Loading-Unloading system. Laser Experts re-imagined the whole traditional pipe cutting process and created a series of machines, which provides a comprehensive answer to complicated industrial demands. These machines can precisely process varied tube shapes like square, round, rectangular tubes, various angles and channels as well as some angle profiles.

These machines are well-known for their flexibility and innovative features, making them a must-have for the sheet metal industry. Feature-loaded 2d sheet metal laser cutting machines are part of the SLTL Group’s trademark Brahmastra Laser Cutting series. It is designed to help the modern-day manufacturer achieve optimum control of production, both qualitative and quantitative. The system is equipped with SLTL’s in-house developed software, making it the most robust machine in the market.

SLTL has created and developed 3D Fiber Laser Cutting Machine for a variety of applications to achieve higher quality output with less gas consumption. The advanced multiple axes integrated robotic automation system is equipped with intelligent capabilities for conveying various operations. It can execute increased and high-efficiency laser cutting of the most complicated 3D components in one go.

Interested In a Product?

Pricing, Technical Data & More

Testimonials

Explore our blogs for a resourceful insight into the infinite opportunities of the laser world.

Machine Hardware, Gas, Safety and Security etc....

Fiber Laser cutting is one of those diversified laser solutions that is highly prioritized by many of the industries.

Igniting Innovation and Redefining Welding Standards across Various Industrial Sectors

24*7 service support and technical assistance. You’re welcome to visit our office for other insights

E-30, Electronic Estate, G. I. D. C.,

Sector - 26, Gandhinagar - 382 028

Gujarat, India.