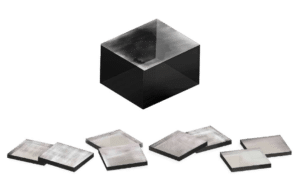

Introducing SLTL’s Hallmark Green Edge, the ultimate diamond slicing solution that exceeds all expectations. With a focus on mechanical stability, this cutting-edge machine delivers exceptional results while providing user-friendly software for enhanced productivity.

The Green Edge stands out with its green laser source, producing a finely tuned beam for unmatched diamond processing capabilities. It has become the go-to instrument for diamond manufacturers who prioritize superior quality.

Designed with the consumer in mind, the Hallmark Green Edge is a powerful machine that swiftly completes tasks. Its green laser ensures precise and waste-free processing, while our advanced Hi-Tech software enables seamless automation for an untroubled experience. With advanced consistent perfection in cuts and angles, this machine guarantees flawless results. Combined with intuitive software, it offers a seamless and effortless user experience.