The agricultural industry in India is currently experiencing rapid growth. An increasing amount of specialized, automated, and diverse agricultural machinery and equipment has offered intelligent solutions in response to the ongoing growth in the demand for agricultural machines. Using agricultural machinery and equipment can reduce the amount of physical labor required for high-intensity farming operations. To address the issue of a lack of agricultural output, boost agricultural development, and effectively increase agricultural production power, mechanized equipment replaces all aspects of farming and irrigation.

One of the best uses of laser cutting machine is in the manufacturing of Rotavator. Let’s know what rotavator is and how it is made.

What is a Rotavator?

A rotavator is a tractor-drawn tool that is primarily used for preparing seed beds in one or two passes. It can also be used to remove and mix leftovers from crops like sugarcane, wheat, and maize, among others. This improves soil health and also saves money, time, fuel, and energy.

It is a powered device that prevents and controls crop diseases and pest invasion by using rotating blades to prepare the land and provide the best possible soil conditions. A multifunctional farm tool like a rotavator, which mechanically pulverizes, cuts, mixes, and levels soil in a single pass, is needed for this soil manipulation and preparation.

This motorized device fulfills numerous uses and consequently performs numerous tasks. To comprehend the importance of rotary tillers, we must first delve into the nuances and comprehensive dissection of its different components and their corresponding proficiencies.

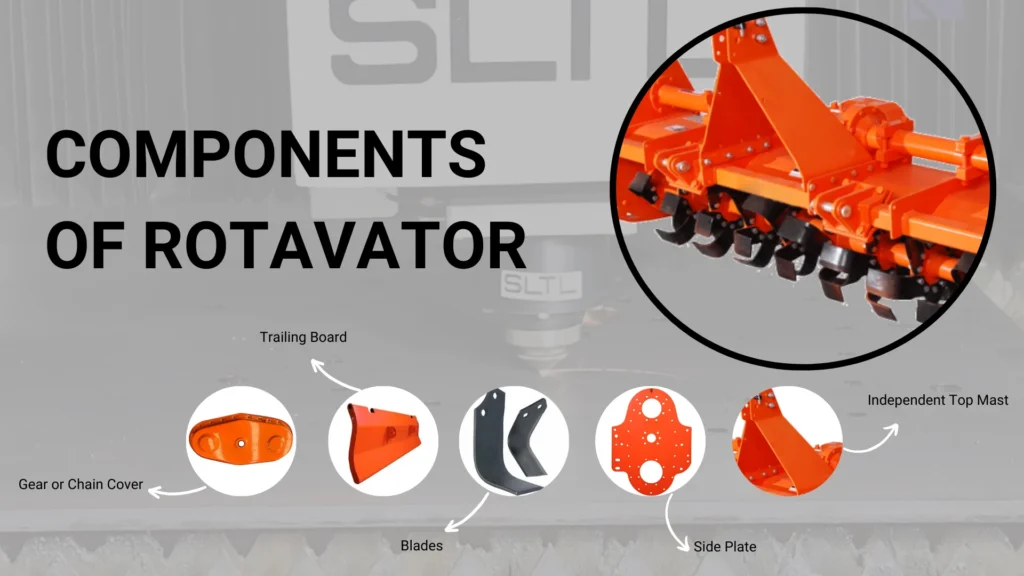

A rotavator is made up of various parts, including:

- Independent top mast

- Single or multispeed gear box

- Chain or gear cover part flange

- Rotary/rotating blades

- Cardan shaft

- Rotor shaft

- Trailing board

- Frame and cover

- Adjustable curved flats (skid)

- Offset adjustable frame

Let’s dive deep into the manufacturing process of each and every part of the rotavator.

Independent top mast

Imagine you have a tractor, and that tractor has a special power source called the Power Take-Off, or P.T.O. It’s like a power outlet on the back of the tractor.

Now, there’s a farming tool called a rotavator. This is a machine used for plowing and preparing the soil. It needs power to work. The tractor’s P.T.O is like the power supply for this tool.

The “independent top mast” is a part that helps transfer this power from the tractor’s P.T.O to the rotavator. It’s like a bridge that connects the tractor’s power to the rotavator so it can do its job.

Now, depending on where the power comes from, a rotavator can be either “engine-operated” or “tractor-drawn.” If it gets its power directly from the tractor, it’s tractor-drawn. If it has its own engine providing power, it’s engine-operated.

So, in simple terms, the independent top mast is like the link that makes sure the power from the tractor gets to the rotavator, allowing it to do the soil preparation work, and depending on the rotavator, it might either be pulled by the tractor or have its own engine.

A laser cutting machine can be used to cut materials, including the components of an independent top mast. A computer numerical control (CNC) program is typically used to guide the laser in creating the desired shapes and patterns. The laser beam is focused on the material, and it cuts through by melting, burning, or vaporizing it.

Chain or gear cover part flange

A laser cutting machine can be used to cut chain or gear cover part flanges. Chain or gear cover part flanges, often made of metal, can be accurately cut using a laser cutting machine.

Laser cutting offers several advantages:

Precision: Laser cutting provides high precision and accuracy, allowing for intricate and detailed cuts. This is crucial for parts like flanges where precise measurements are important.

Versatility: Laser cutting machines can handle a variety of materials, including different types of metals. This makes them suitable for cutting chain or gear cover part flanges made of materials like steel or aluminum.

Clean Cuts: Laser cutting produces clean and smooth cuts, minimizing the need for additional finishing processes. This is important for maintaining the integrity and functionality of the parts being cut.

Automation: Many laser cutting machines are computer-controlled and can be programmed to cut specific shapes and patterns automatically. This improves efficiency and reduces the likelihood of errors.

However, it’s essential to consider the specific requirements of the material and the design of the part. Additionally, safety measures must be followed when working with laser cutting machines, as they involve the use of high-powered lasers.

Rotary/rotating blades

Rotavator Blades are used in Rotary tillers, in order to deeply dig the soil and taking out the roots, by rotating the blades. Laser cutting machines can be particularly useful for cutting rotary or rotating blades. Here are several ways in which laser cutting machines assist in this process:

Precision Cutting:

Laser cutting provides high levels of precision, allowing for intricate and accurate cuts. This is crucial when dealing with rotary blades, where even small deviations can affect the performance and balance of the blades.

Complex Geometries:

Rotary blades often have complex shapes and intricate geometries. Laser cutting machines can easily handle these complexities, producing clean and sharp edges for blades with intricate designs.

Customization:

Laser cutting is a versatile process that allows for easy customization. Manufacturers can quickly adapt the cutting patterns and designs to meet specific requirements, whether it’s for different blade sizes, shapes, or features.

Automation:

Laser cutting machines can be integrated into automated production lines. This helps in mass production of rotary blades with consistent quality, reducing human error and increasing overall efficiency.

Reduced Material Waste:

Laser cutting is a non-contact process, which means there is minimal material wastage compared to traditional cutting methods. This is especially important when working with expensive materials or when precision is paramount.

Minimal Heat Affected Zone:

Laser cutting produces a very small heat-affected zone, minimizing the risk of thermal distortion in the material being cut. This is crucial for maintaining the structural integrity of the blades, as excessive heat can alter the properties of the material.

Versatility of Materials:

Laser cutting machines can work with a wide range of materials, including metals, plastics, and composites. This versatility allows manufacturers to choose the most suitable material for the specific application of the rotary blades.

Fast Processing Speed:

Laser cutting is a high-speed process, enabling manufacturers to produce rotary blades quickly and efficiently. This is especially beneficial for meeting tight production schedules and demands.

Clean Cut Edges:

Laser cutting produces clean and burr-free edges, which is crucial for rotary blades where any imperfections could affect performance. The smooth edges also reduce the need for additional finishing processes.

Minimal Mechanical Stress:

Laser cutting exerts minimal mechanical stress on the material, contributing to the longevity and durability of the rotary blades.

Trailing board

Laser cutting machines can be used to cut the trailing board of a rotavator. The trailing board, also known as a tailboard or rear board, is a component located at the back of the rotavator and plays a role in soil and residue management. The specific part that is cut using a metal laser cutting machine could include various features or patterns on the trailing board.

Rotavator Side Plate

Laser cutting ensures unparalleled precision, allowing for the creation of side plates with intricate designs and exact measurements, enhancing the overall quality of the rotavator. The laser cutting process produces clean and smooth edges, eliminating the need for additional finishing processes. This results in a polished final product with a professional appearance. Laser cutting machines can be integrated into automated production lines, further streamlining the manufacturing process and reducing manual labor, resulting in increased efficiency and cost-effectiveness.

Conclusion

Thus the use of a fiber laser cutting machine in the production of a rotavator offers several advantages. Fiber laser technology enables precise and efficient cutting of materials, enhancing the overall quality and accuracy of the components. This method also allows for intricate designs and customization, contributing to the versatility of rotavator manufacturing. Additionally, the speed and cost-effectiveness of fiber laser cutting make it a preferred choice for producing high-quality rotavators in a streamlined and economical manner.