SLTL Group, a renowned name in laser cutting technology, is a top manufacturer of laser cutting machines in Bangalore. We offer a diverse range of laser cutting solutions, including 2D, 3D, and specialized machines for pipe and tube cutting, catering to various industrial needs. Our machines are designed to deliver precision and efficiency, capable of handling a wide array of materials like brass, aluminum, copper, mild steel, stainless steel, and more.

Our laser cutting machines feature a broad power range from 1 kW to 30 kW, allowing for versatile applications from fine, detailed work to heavy-duty cutting tasks. Each machine is built with advanced technology to ensure superior performance, reliability, and minimal downtime, backed by our 24/7 customer support service.

Ever since incorporation, we have been making our way through futuristic technology and ground-breaking innovations.

At SLTL Group, we are leaders in laser cutting technology, offering advanced fiber laser cutting machines designed to meet the diverse needs of industries. If you are looking for a laser cutting machine in Bangalore, we provide high-performance solutions tailored for precision and efficiency. Based in Bangalore, we take pride in being one of the top laser cutting machine manufacturers in India, delivering high precision, efficiency, and quality in metal cutting. Our machines are widely used in various industries, from automotive and aerospace to fabrication and construction, helping businesses achieve faster and more accurate cutting solutions.

Our laser cutters are built to handle all types of metal cutting tasks with ease. Whether it’s stainless steel, aluminum, copper, or other materials, our machines ensure high-speed and precise cutting with minimal waste.

SLTL Group offers a variety of laser cutting machines to cater to different industries. Whether you need a compact fiber laser cutter for small businesses or a high-power laser cutting system for heavy-duty applications, we have the right solution.

SLTL Group is proud to serve businesses across Bangalore, providing laser cutting machines that help industries improve efficiency and reduce production time. Bangalore, known for its industrial hubs and manufacturing sectors, is home to leading fabrication units and metal processing companies that rely on high-quality cutting machines for metal. Our machines are trusted by businesses in Peenya Industrial Area, one of India’s largest industrial zones.

Contact us today to explore the best laser cutter for your business and enhance your production capabilities.

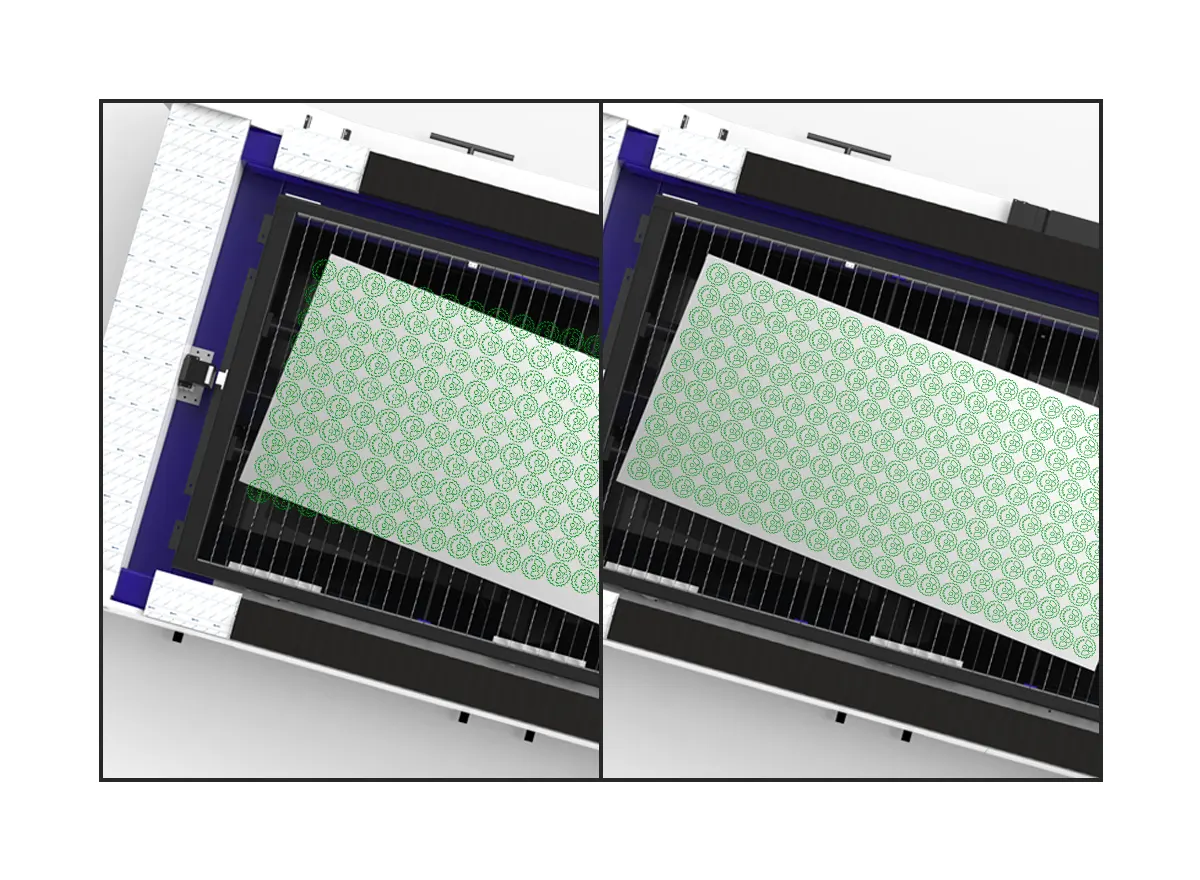

Speed up the cutting process by eliminating the manual alignment of the sheet for each cutting operation. Auto-sheet orientation feature enables automatic orienting of the program to that angle in which the sheet has been kept which ultimately eliminates the non-productive time of rearranging the sheet.

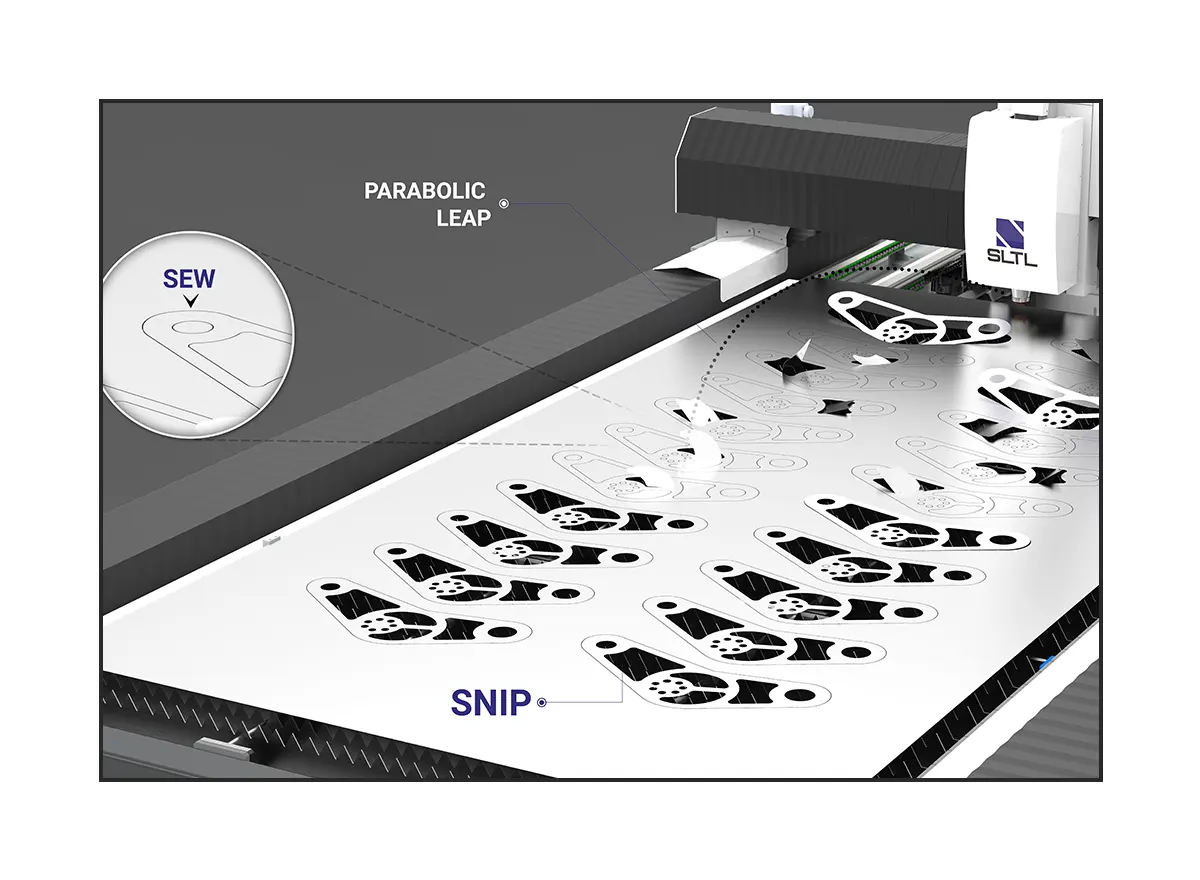

Equipped with a powerful mechanical structure the Infinity F1 is designed with an anti-collision system. This smart feature allows you to use methods like snipping, sewing, and parabolic leaping to restrict the movement of the sheet when cutting, for uninterrupted material processing. The anti-collision mechanism minimizes non-productive times which can happen due to parts tipping over when cutting thin sheet metal and makes your machine permanently productive.

One of the key features to process high-speed cutting applications in Fiber laser cutting machines, FLYCUT performs the continuous cutting of the desired shape without lifting up the laser head giving a boost to the processing speed by reducing the head travel movements.

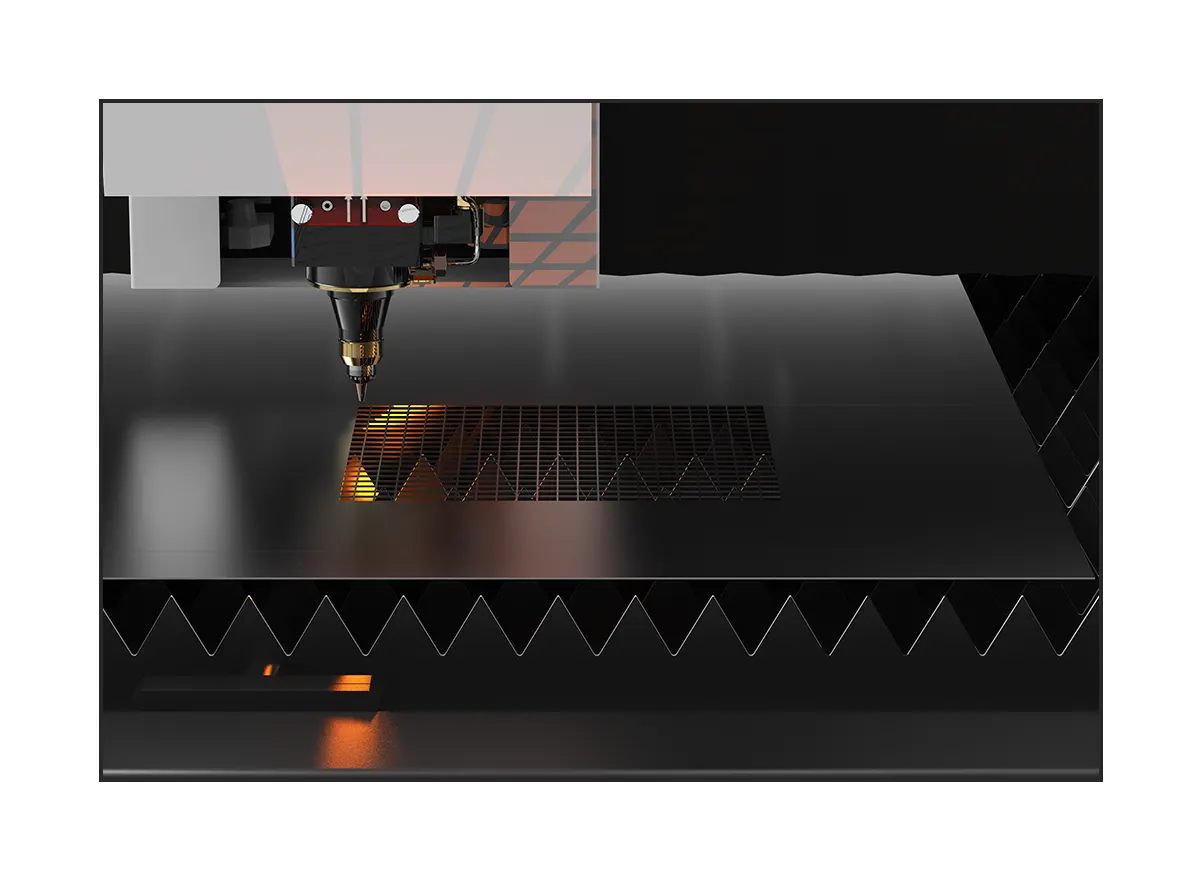

Infinity F1 Fiber Laser Cutting Machines from SLTL include a dynamic fume extraction technology that opens the fume collecting vault of the machine base precisely where the application is being conducted. These fume ducts collect the fumes and send them to the dust collection unit in order to prevent the toxic fumes produced during the metal processing from being released into the environment.

The laser head maintains a consistent gap with the material. If in case of varying material properties, through the online software, the laser head could be adjusted, during operation to get the proper cut quality with precision & accuracy.

| Unit | Working Range 2D | |||||||

|---|---|---|---|---|---|---|---|---|

| 1515 | 3015 | 4020 | 6520 | 6525 | 8025 | |||

| Maximum Working Range | X Axis | mm | 1525 (60.03″) | 1525 (60.03″) | 2100 (82.6*) | 2100 (82.6″) | 2550 (100.3″) | 2550 (100.3″) |

| Y Axis | mm | 1525 (60.03″) | 3100 (122*) | 4100 (161.4″) | 6600 (259.8*) | 6600 (259.8″) | 8050 (316.9″) | |

| Z Axis | mm | 150 (5.9″) | 299 (11.8″) | 300 (11.8″) | 301 (11.8″) | 302 (11.8″) | 450 (17.7″) | |

| Z Axis (UHP) | mm | 150 (5.9″) | 300 (11.8″) | 300 (11.8″) | 301 (11.8″) | 450 (17.7″) | 451 (17.7″) | |

| Maximum Workpiece Weight*** | kgs | 220 | 900 | 1650 | 2650 | 3100 | 7800 | |

| (UHP) | kgs | 220 | 1100 | 3150 | 5100 | 6350 | 7800 | |

| Positioning Precision | mm/m | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 | |

| Repeatability | mm/m | ±0.02 | ±0.02 | ±0.02 | ±0.02 | ±0.02 | ±0.02 | |

| Maximum Rapid | Simultaneous | m/min | 120 | 170 | 125 | 125 | 125 | 125 |

| Maximum Acceleration | m/s2 | 20 | 20 | 15 | 15 | 15 | 15 | |

| Laser Power | 3 kW | 4 kW | 6 kW | 8 kW | 10 kW | 12 kW | 15 kW | 20 kW | 30 kW |

|---|---|---|---|---|---|---|---|---|---|

| Cutting Thickness on Metals mm (inch) | |||||||||

| Mild Steel (MS) (02) | 20 (3/4″) | 22 (7/8″) | 25 (1″)* | 28 (9/8″)* | 30 (19/16″)* | 40 (25/16″)* | 45 (7/4″)* | 50 (31/16″)* | 60 (19/8″)* |

| Mild Steel (MS) (N2 / Air) | 6 (1/4″) | 6 (1/4″) | 8 (5/16″) | 10 (3/8″) | 12 (1/2″) | 12 (1/2″) | 16 (5/8″) | 20 (13/16″) | 25 (1″)* |

| Stainless Steel (SS) (02) | 10 (3/8″) | 10 (3/8″) | 10 (3/8″) | 10 (3/8″) | 10 (3/8″)* | 10 (3/8″) | 10 (3/8″) | 10 (3/8″) | 10 (3/8″) |

| Stainless Steel (SS) (N2 / Air) | 8 (5/16″) | 10 (3/8″) | 16 (5/8″)* | 20 (13/16″) | 25 (1″)* | 30 (19/16″)* | 32 (5/4″)* | 35 (11/8″)* | 40 (25/16″)* |

| Aluminum (AL) (N2) | 8 (5/16″) | 10 (3/8″) | 16 (5/8″)* | 20 (13/16″) | 25 (1″)* | 30 (19/16″)* | 32 (5/4″)* | 35 (11/8″)* | 40 (25/16″)* |

| Brass (Br) (N2) | 6 (1/4″) | 8 (5/16″) | 12 (1/2″) | 16 (5/8″) | 20 (13/16″) | 25 (1″)* | 30 (19/16″)* | 32 (5/4″)* | 35 (11/8″)* |

| Copper (Cu) (02) | 5 (3/16″) | 6 (1/4″) | 8 (5/16″) | 10 (3/8″) | 12 (1/2″) | 16 (5/8″) | 18 (11/16″) | 20 (13/16″) | 22 (7/8″) |

| Galvanized Iron (GI) (N2 / Air)# | 3 (1/8″) | 3 (1/8″) | 3 (1/8″) | 3 (1/8″) | 3 (1/8″) | 3 (1/8″) | 3 (1/8″) | 3 (1/8″) | 3 (1/8″) |

| Power Consumption** | 20 kW | 24 kW | 32 kW | 40 kW | 48 kW | 56kW | 68kW | 85kW | 120kW |

| Type | Working Area (2D) | |||||

|---|---|---|---|---|---|---|

| 1515 | 3015 | 4020 | 6520 | 6525 | 8025 | |

| Machine Width | 2820 | 2280 | 3400 | 3300 | 3900 | 3900 |

| Machine Height | 2300 | 2190 | 2200 | 2200 | 2200 | 2350 |

| CNC Gantry | 4700 | 6000 | 6700 | 9300 | 9300 | 10900 |

| Dual Pallet | NA | 3300 | 4400 | 6900 | 6900 | 8500 |

| Total Machine Length | 6700 | 9300 | 11100 | 16200 | 16200 | 19400 |

| Space Required for Accessories | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 |

| Total Machine Width with Accessories | 3300 | 4280 | 5900 | 5900 | 6500 | 6500 |

| Width of Operating Panel | 600 | 600 | 600 | 600 | 600 | 600 |

| Length of Operating Panel | 430 | 430 | 430 | 430 | 430 | 430 |

* The quality of the cut depends upon the attributes of metal, its surface properties and the conditions in which cutting operations are done. Metals with high thickness tend to have striation at lower edges.

** The power consumption indicated in the table is measured on the machine’s peak performance. It includes the connected load of the laser source, controller, fume extractor and chiller.

***Maximum thickness of full-size sheet is limited by weight capacity of respective variant.

#Galvanized Iron (GI) only comes up to 3mm thickness in market.

• Light Curtain

• Nozzle Cleaning

• Filter Dust Collector

• Countersink

• Calibration | Vision Check

• Pneumatic Laser Safety Doon

• Smart Camera

• Auto Nozzle Changer, Centering

• QR Code / Barcode Scanner

Support

Online Service Response 100%

Physical Response

Delighted Customers

Interested In a Product?

Pricing, Technical Data & More

Explore our blogs for a resourceful insight into the infinite opportunities of the laser world.

You might have witnessed in your regular day at shop floor that the metal sheets of cut parts are offloaded by an operator.

SLTL Group is the company that has defined what is called a "Trailblazer".

Have you ever pondered about the laser technology that everybody seems to be talking about? Actually, you would be surprised to know that Laser is just an acronym for Light Amplification by Stimulated Emission of Radiation.

24*7 service support and technical assistance. You’re welcome to visit our office for other insights

E-30, Electronic Estate, G. I. D. C.,

Sector - 26, Gandhinagar - 382 028

Gujarat, India.