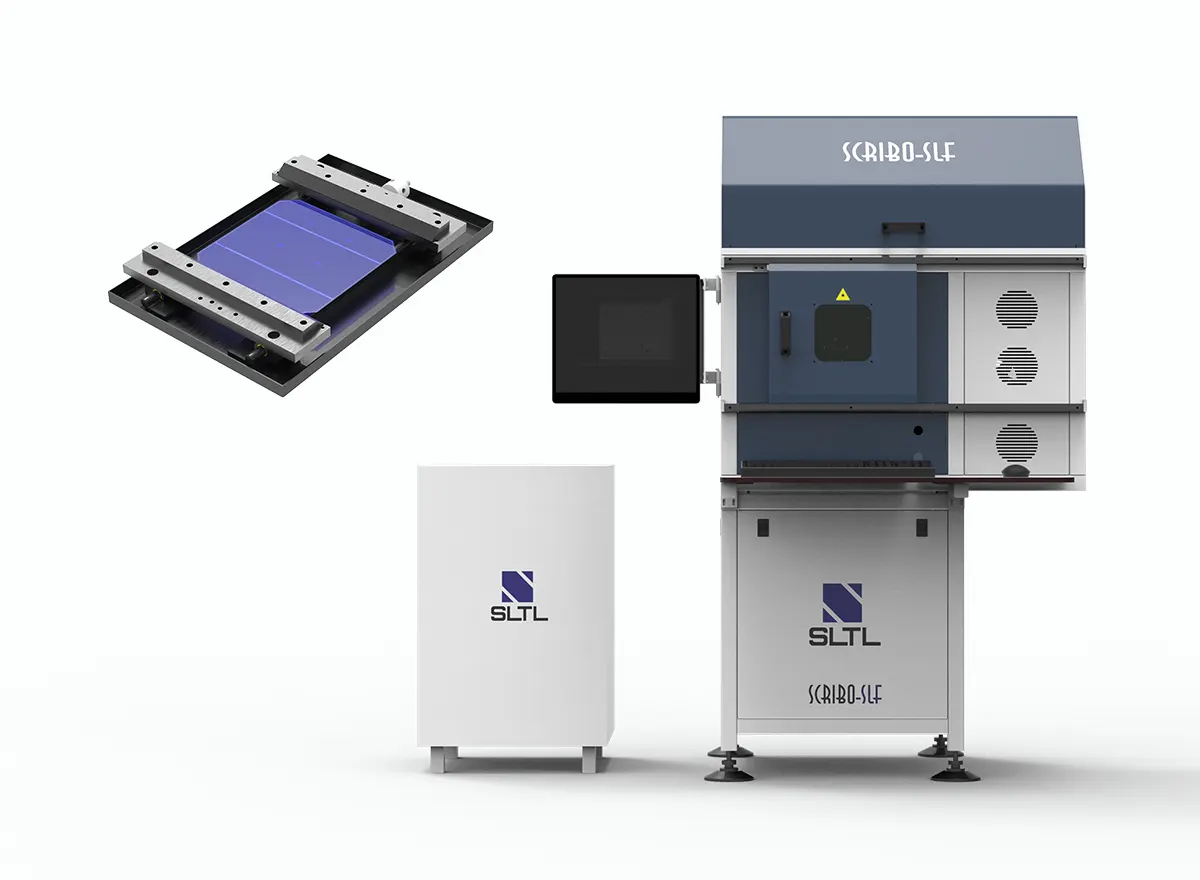

SLTL introduced a state of art laser solution for solar cell scribing & cutting with a more stable performance. The machine features the latest technology support so as to provide lasting work support by SLF for new generation High Power Laser Cutting machines, for precise solar cell metal cutting. The SCSS has two variations based on beam generation and transmission- Fiber Lasers and Diode Lasers. Further, these laser scribing-dicing machines find use in the photovoltaic industry where these are used for scribing polycrystalline and monocrystalline silicon wafers, and non-crystalline silicon solar cells. Its structural construction is rigid and heavy for vibration-free and high-accuracy scribing & cutting applications.

Ever since incorporation, we have been making our own way through futuristic technology and ground-breaking innovations.

The machine features the latest technology support so as to provide lasting work support by SLF for new generation High Power Laser Cutting machines, with high-precision solar cell metal cutting.

Automation in the Solar cell cutting machine has changed the scenario of the production industry. The machine is very stable, utilizes very low electricity, and automatically processes the solar cell metal chips which have made it possible to have an uninterrupted production flow.

The Solar Cell Cutting machine executes the operation in the fluidic way and allow the cells to get perfectly cut at exactly required measurements.

The structural construction of the machine is rigid and vibration-free and effective for cutting applications. The machine also includes vacuum plates, which do not have any potential for errors in solar cell breakdown.

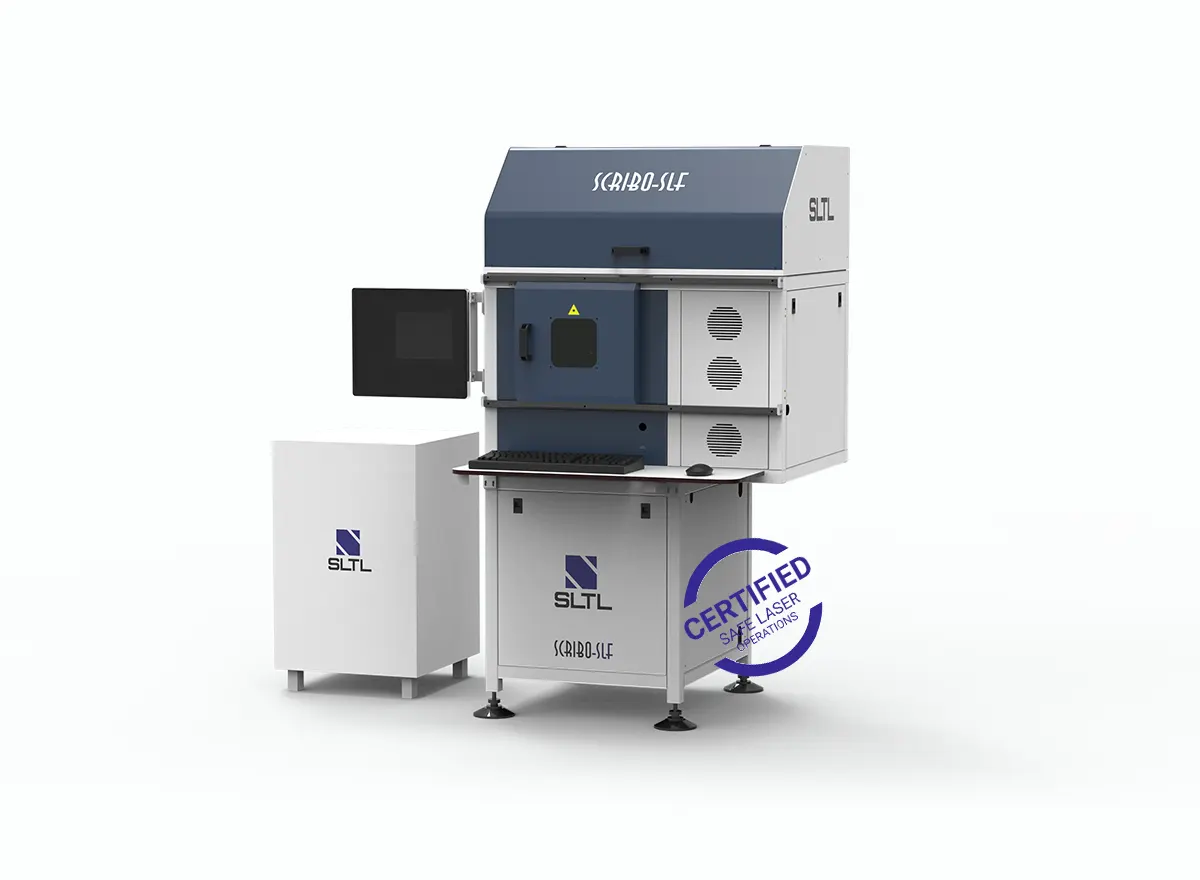

Extreme safety standards are considered while making this machine to eliminate hazardous situations at facilities and keep the machine operators as safe and secure as possible.

With the proficient machine, it has also the most user-friendly operating system designed for laser scribing machines, a real-time display to write paths in an in-built camera.

| Model | SCRIBO-SLF |

|---|---|

| Laser | Fiber Laser |

| Frame Design | Compact |

| Laser Wavelength | 1064nm |

| Transverse Mode | TEMoo |

| Beam Quality | M² < 1.8 |

| Average Power | 20 W / 30 W / 50 W |

| Resolution | 1 micron |

| Line width | < 30 micron |

| Repeatability | ≤3 micron |

| Max. Scribing Speed | 200* mm / sec |

| Laser Repetition Freq. | 20 KHz to 80 KHz |

| Axis | 175 x 175 mm / 312 x 312 mm |

| Controller | PC Based |

| Cooling | Air Cooled |

| Dimension | 1300 x 1125 x 1450 mm |

| Connected Lode | 230 V / 50 Hz, 0.46 kW |

| Camera | In-Built |

| Z Axis | Manual |

| Software | Dedicated software for solar cell cutting application |

Support

Online Service Response 100%

Physical Response

Delighted Customers

Interested In a Product?

Pricing, Technical Data & More

World’s best high-speed fiber laser forming machines with precise and accurate processing for all your business requirements such as metal sheet cutting, welding, cleaning, marking etc.

Ever since incorporation, we have been making our own way through futuristic technology and ground-breaking innovations.

Explore our blogs for a resourceful insight into the infinite opportunities of the laser world.

With the intervention of technology SLTL Group has led the way through futuristic solutions and taken the National legacy to foreign land

We've got the vision to deliver continuous innovation, working in the future.

As technology improves and changes are done at a quick pace, the industry is reaching new heights.

24*7 service support and technical assistance. You’re welcome to visit our office for other insights

E-30, Electronic Estate, G. I. D. C.,

Sector - 26, Gandhinagar - 382 028

Gujarat, India.