Introducing the Hallmark Evoq, the ultimate diamond machine for precision coring and slicing of lab-grown diamonds. With its cutting-edge technology and advanced features, the Hallmark Evoq offers unparalleled accuracy and efficiency in the production process.

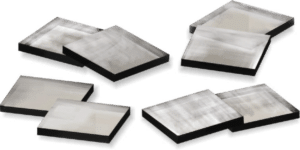

Designed to meet the demands of the diamond industry, the Hallmark Evoq boasts a parallel and extremely narrow laser beam kerf, ensuring smooth and precise slices with excellent surface smoothness. This precision technology guarantees maximum production of slices, enhancing the value of each stone by maximizing the number of possible slices. This technology guarantees accuracy at its best, allowing for consistent and high-quality results with minimal human intervention.

With the integration of in-house software and updated technology, the Hallmark Evoq offers maximum productivity and efficiency. For those in the diamond industry seeking a state-of-the-art solution for coring and slicing lab-grown diamonds, the Hallmark Evoq is the epitome of excellence.