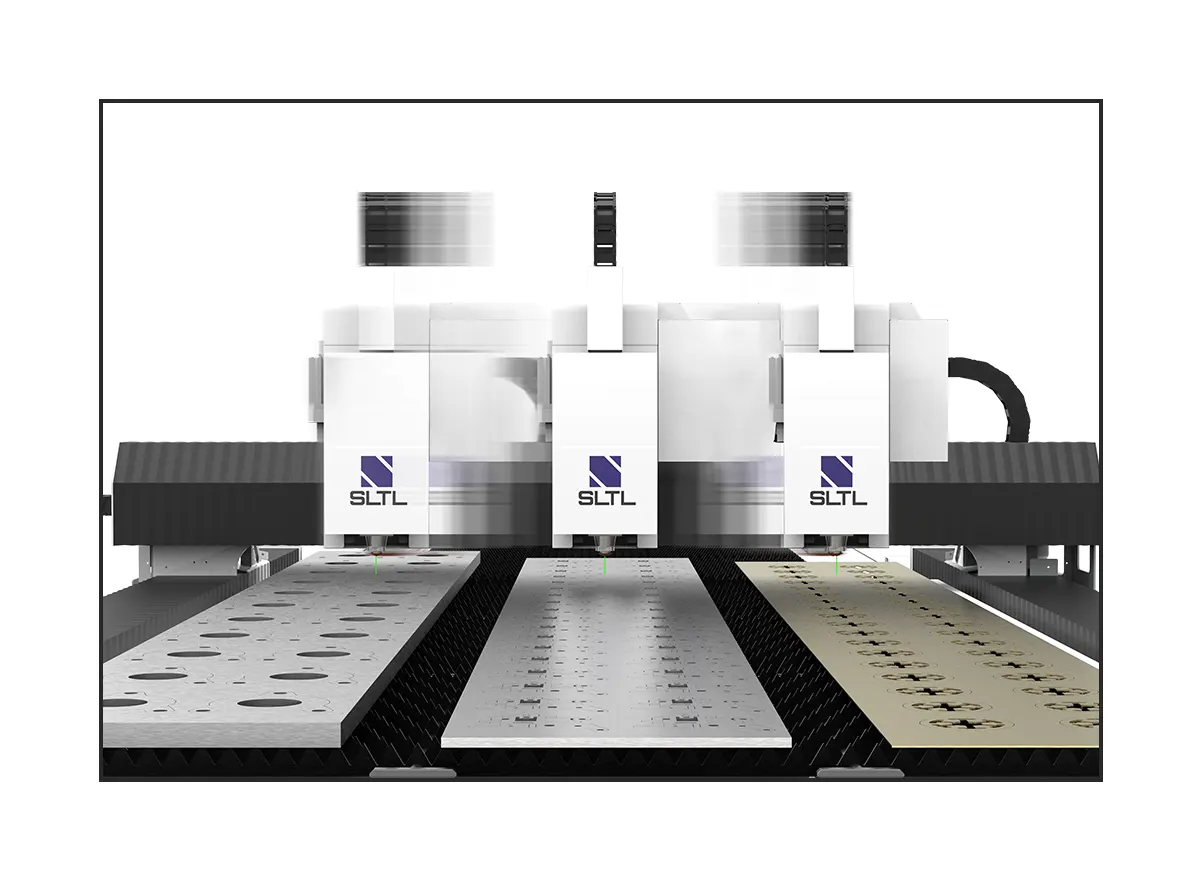

PRIME is a byproduct of the SLTL Group’s trademark Brahmastra Laser Cutting series. It is designed to help the modern-day manufacturer achieve optimum control of production, both qualitative and quantitative. The system is equipped with SLTL’s in-house developed software, making it the most robust machine in the market.

The intelligent hardware and software enable variable cutting at high rates without sacrificing cut quality or output. The system is designed for fabricators ready to start with the Laser Cutting Technology and expecting the highest results at an economical price. These machines are well-known for their flexibility and innovative features, making them a must-have for the sheet metal industry.

Ever since incorporation, we have been making our own way through futuristic technology and ground-breaking innovations.

Prime laser cutting machine is the industry standard, with excellent cutting quality and productivity.

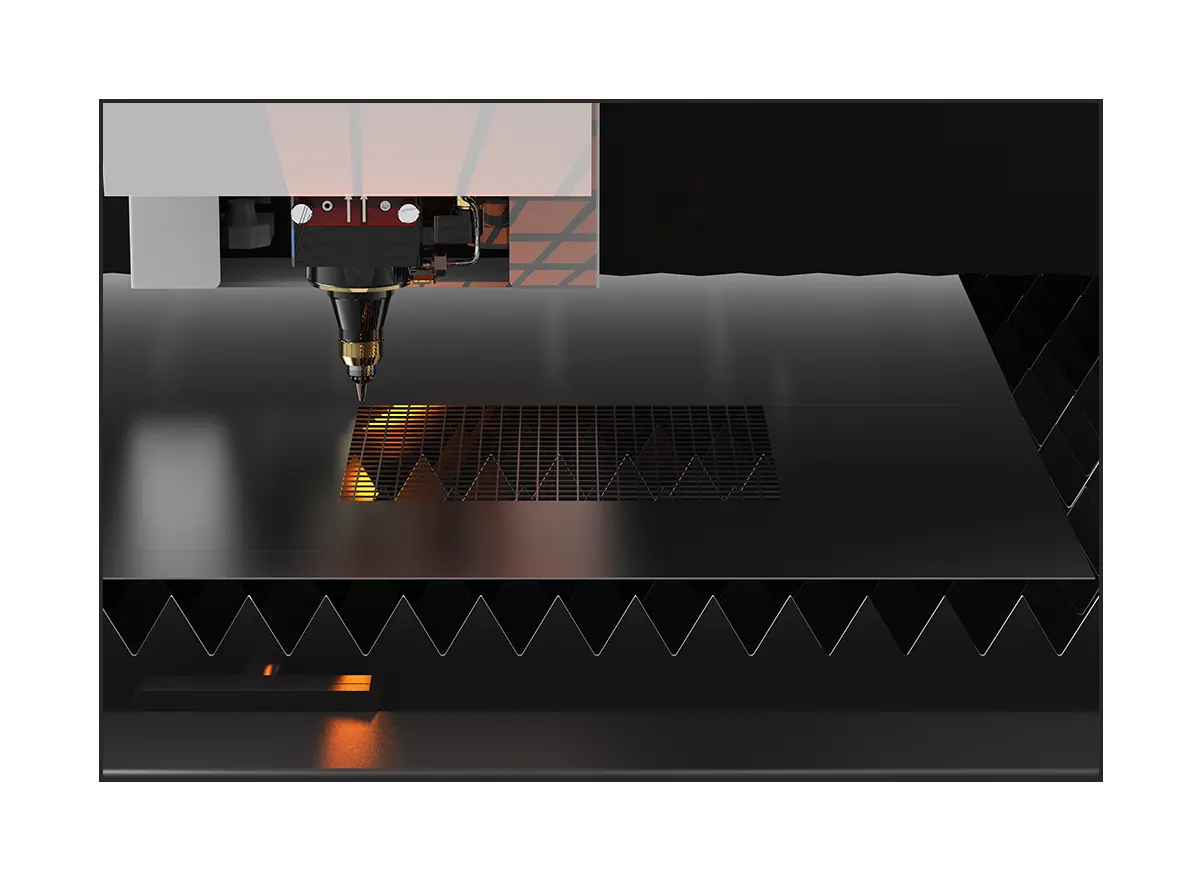

One of the key features to process high-speed cutting applications in Fiber laser cutting machines, FLYCUT performs the continuous cutting of the desired shape without lifting up the laser head giving a boost to the processing speed by reducing the head travel movements.

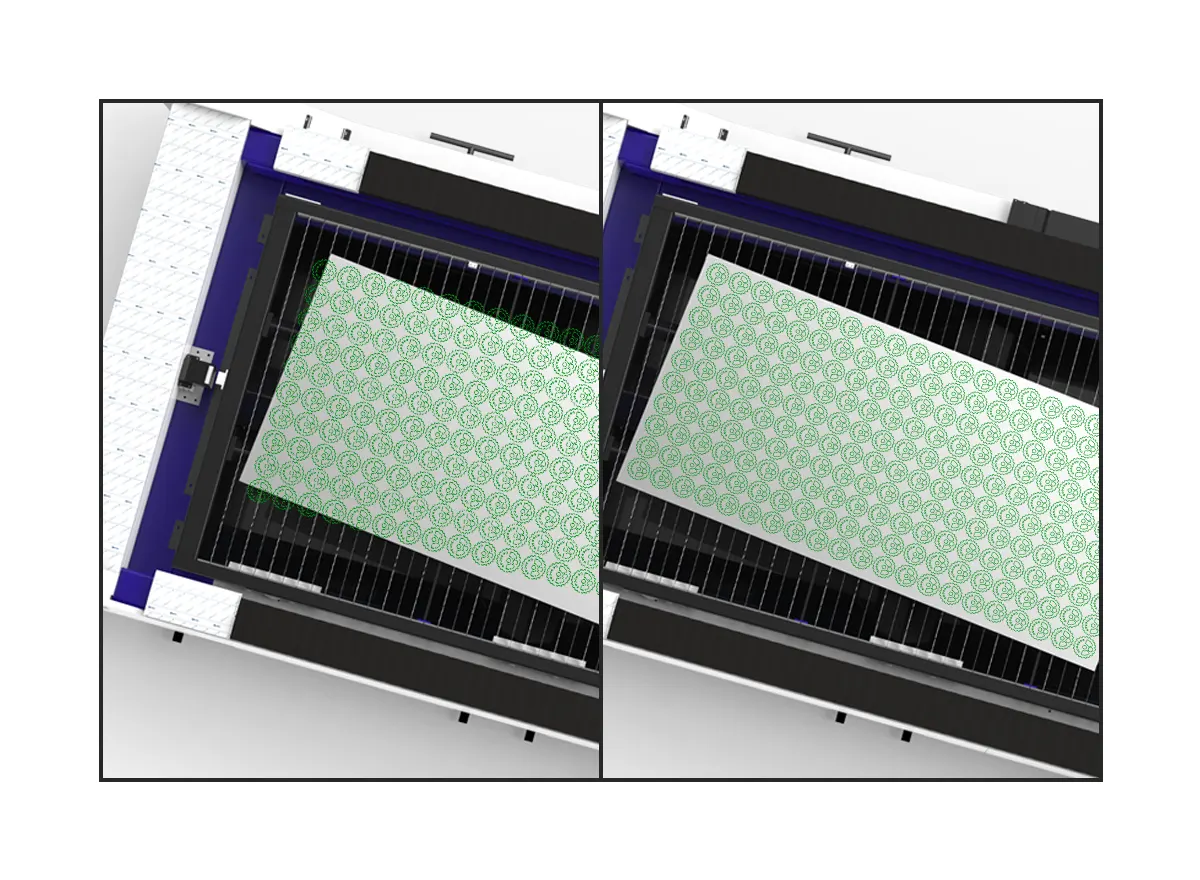

Speed up the cutting process by eliminating the manual alignment of the sheet for each cutting operation. Auto-sheet orientation feature enables automatic orienting of the program to that angle in which the sheet has been kept which ultimately eliminates the non-productive time of arranging the sheet.

Futuristic laser machine- Prime is integrated with Smart software that having a capability to draw and edit the basic all shapes in the software itself only. It is a user-friendly software that is easy to run the machine with all the foremost functionality available on the dashboard.

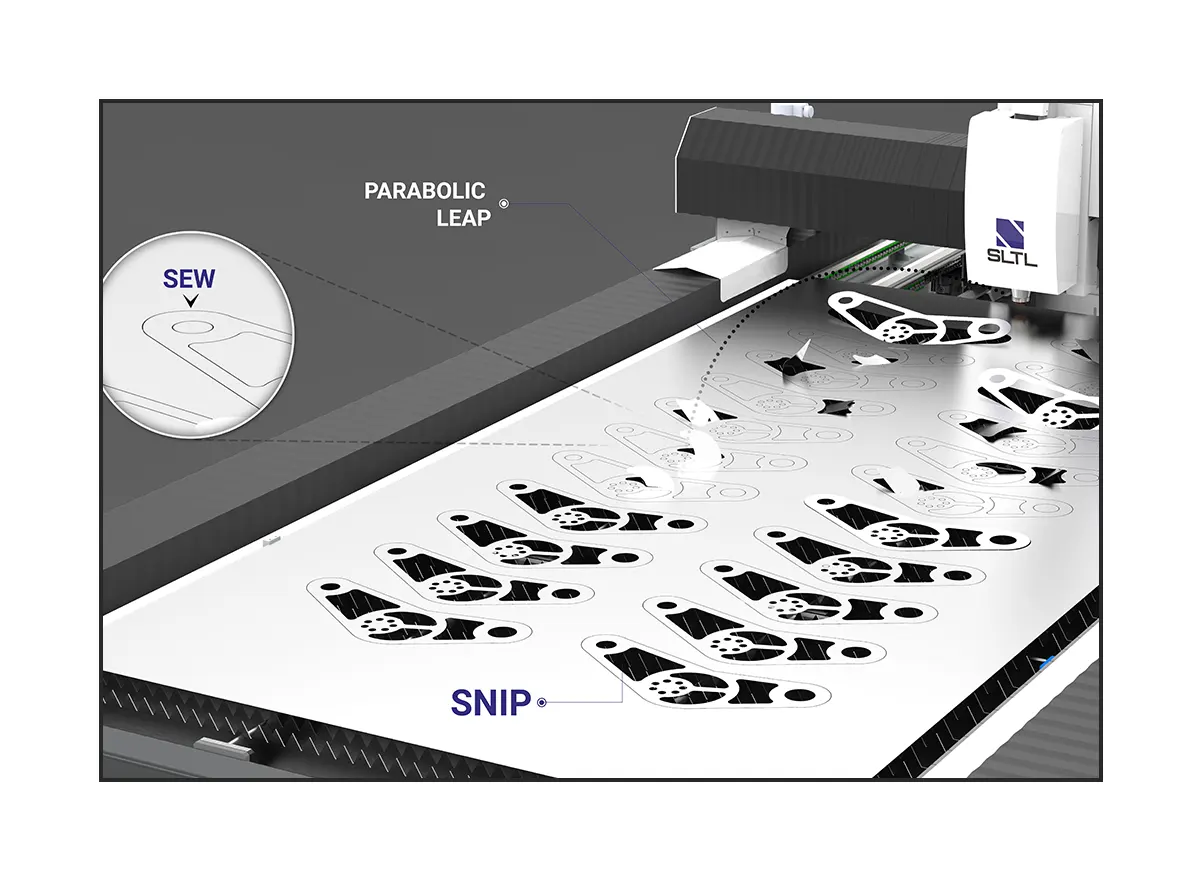

The anti-collision mechanism consists of snip, sew and parabolic leaps, this minimizes non-productive times which can happen due to parts tipping over when cutting thin sheet metal, and ensures that the sheet cut-out pieces do not collide with the laser head while processing and makes your machine permanently productive.

Prime is equipped with ball support sheet loading/unloading mechanism which helps to load and unload the sheet effortlessly, ultimately eliminating the non-productivity time.

With a dynamic motorized lens function, Prime can automatically adjust the focus to the most suitable position when processing different materials and thicknesses. It automatically changes the focus of the lens as per the object & the application. This will significantly improve the efficiency of the laser cutting machine and reduce the piercing time of thick sheets significantly with a high level of productivity.

| Unit | 1515 | 3015 | 4020 | 6520 | 6525 | ||

|---|---|---|---|---|---|---|---|

| Maximum Working Range | X Axis | mm (inch) | 1525 (60″) | 1525 (60″) | 2100 (82.6″) | 2100 (82.6″) | 2550 (100.3″) |

| Maximum Working Range | Y Axis | mm (inch) | 1525 (60″) | 3100 (122″) | 4100 (161.4″) | 6600 (259.8″) | 6600 (259.8″) |

| Maximum Working Range | Z Axis | mm (inch) | 150 (5.9″) | 300 (11.8″) | 300 (11.8″) | 300 (11.8″) | 300 (11.8″) |

| Maximum Workpiece Weight | kgs | 220 | 900 | 1650 | 2650 | 3100 | |

| Positioning Precision | mm/meter | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 | |

| Repeatability | mm/meter | ±0.02 | ±0.02 | ±0.02 | ±0.02 | ±0.02 | |

| Maximum Rapid | Simultaneous | m/min | 120 | 120 | 120 | 120 | 120 |

| Maximum Acceleration | m/s2 | 15 | 15 | 15 | 15 | 15 |

| Laser Power | 1 kW | 1.5 kW | 2 kW | 3 kW | 4 kW | 6 kW |

|---|---|---|---|---|---|---|

| Mild Steel (MS) (O2) | 10 (3/8”) | 12 (1/2”) | 16 (5/8”) | 20 (3/4”) | 22 (7/8”) | 25 (1”)* |

| Mild Steel (MS) (N2 / Air) | 3 (1/8”) | 4 (3/16”) | 5 (3/16”) | 6 (1/4”) | 6 (1/4”) | 8 (5/16”) |

| Stainless Steel (SS) (O2) | 6 (1/4”) | 6 (1/4”) | 10 (3/8”) | 10 (3/8”) | 10 (3/8”) | 10 (3/8”) |

| Stainless Steel (SS) (N2) | 3 (1/8”) | 4 (3/16”) | 5 (3/16”) | 8 (5/16”) | 10 (3/8”) | 16 (5/8”)* |

| Aluminum (Al) (N2) | 2 (1/16”)** | 3 (1/8”) | 5 (3/16”) | 8 (5/16”) | 10 (3/8”) | 16 (5/8”)* |

| Brass (Br) (N2) | 3 (1/8″)** | 3 (1/8”) | 5 (3/16”) | 6 (1/4”) | 8 (5/16”) | 12 (1/2”) |

| Copper (Cu) (O2) | 2 (1/16”)** | 2 (1/16”) | 3 (1/8”) | 5 (3/16”) | 6 (1/4”) | 8 (5/16”) |

| Galvanized Iron (Gl) (N2 / Air) # | 3 (1/8″)* | 3 (1/8″)* | 3 (1/8″)* | 3 (1/8”) | 3 (1/8”) | 3 (1/8”) |

| Power Consumption*** | 10 kW | 12 kW | 17 kW | 20 kW | 24 kW | 32 kW |

* The quality of the cut depends upon the attributes of metal, its surface properties and the conditions in which cutting operations is done. Metals with high thickness tend to have striation at lower edges

** Not advisable to process, requires special grade material

*** The power consumption indicated in the table is measured on the machine’s peak performance. It includes the connected load of laser source, controller, fume extractor and chiller.

# Galvanized Iron (GI) only comes up to 3mm thickness in market

| Dimension (mm) | |||||

|---|---|---|---|---|---|

| Type | 1515 | 3015 | 4020 | 6520 | 6525 |

| Machine Width | 2280 | 2280 | 3400 | 3300 | 3900 |

| Machine Height | 2200 | 2190 | 2200 | 2200 | 2200 |

| CNC Gantry | 4700 | 6000 | 6700 | 9300 | 9300 |

| Dual Pallet | NA | 3300 | 4400 | 6900 | 6900 |

| Total Machine Length | 6800 | 9300 | 11100 | 16200 | 16200 |

| Space Required for Accessories | 2000 | 2000 | 2000 | 2000 | 2000 |

| Total Machine Width with Accessories | 2300 | 4280 | 5900 | 5900 | 6500 |

| Width of Operating Panel | 600 | 600 | 600 | 600 | 600 |

| Length of Operating Panel | 430 | 430 | 430 | 430 | 430 |

* All the above Figures are in mm (Millimeter).

* Sahajanand Laser Technology Ltd. reserves the right to make changes without any prior intimation or notice.

Support

Online Service Response 100%

Physical Response

Delighted Customers

Interested In a Product?

Pricing, Technical Data & More

World’s best high-speed fiber laser forming machines with precise and accurate processing for all your business requirements such as metal sheet cutting, welding, cleaning, marking etc.

Ever since incorporation, we have been making our own way through futuristic technology and ground-breaking innovations.

Explore our blogs for a resourceful insight into the infinite opportunities of the laser world.

Fiber Laser cutting is one of those diversified laser solutions that is highly prioritized by many of the industries.

Speaking of mighty production machines, Laser cutting machines are one of the major metal processing machines used across the globe.

To triumph the challenges SLTL Group took an initiative for a railway bogie manufacturer. The team learned the flaws in the existing manufacturing process and understood the limitations of the conventional methods of operation.

24*7 service support and technical assistance. You’re welcome to visit our office for other insights

E-30, Electronic Estate, G. I. D. C.,

Sector - 26, Gandhinagar - 382 028

Gujarat, India.