The high-power handheld laser welding system combines the fundamental qualities of an ultra-portable device with uncompromising performance. Designed in new formats, the product’s overall volume is reduced dramatically resulting in an extremely productive and powerful system. This device is a perfect integration of SLTL Group’s Laser Welding Technology and reliable portable structure. The System is a fit for welding complex components as well as large and small components with unmatched strength.

Ever since incorporation, we have been making our own way through futuristic technology and ground-breaking innovations.

The supersonic Laser welding machine is designed to flexibly weld the diversified shapes and sizes of components with the highest strength and seamless joints.

Hertz is a power-packed system with a compact structure ready to move around your work floor. Specifically created to reach the complex parts or spaces of the components which can’t be taken to the machine. The flexible machine is designed in a portable framework to provide strong welding joints to different materials.

Hertz allows operation without any additives or consumables to the welding process. The high-quality welding seam with powerful weld joints can be aesthetically achieved without adding consumables to the laser welding applications.

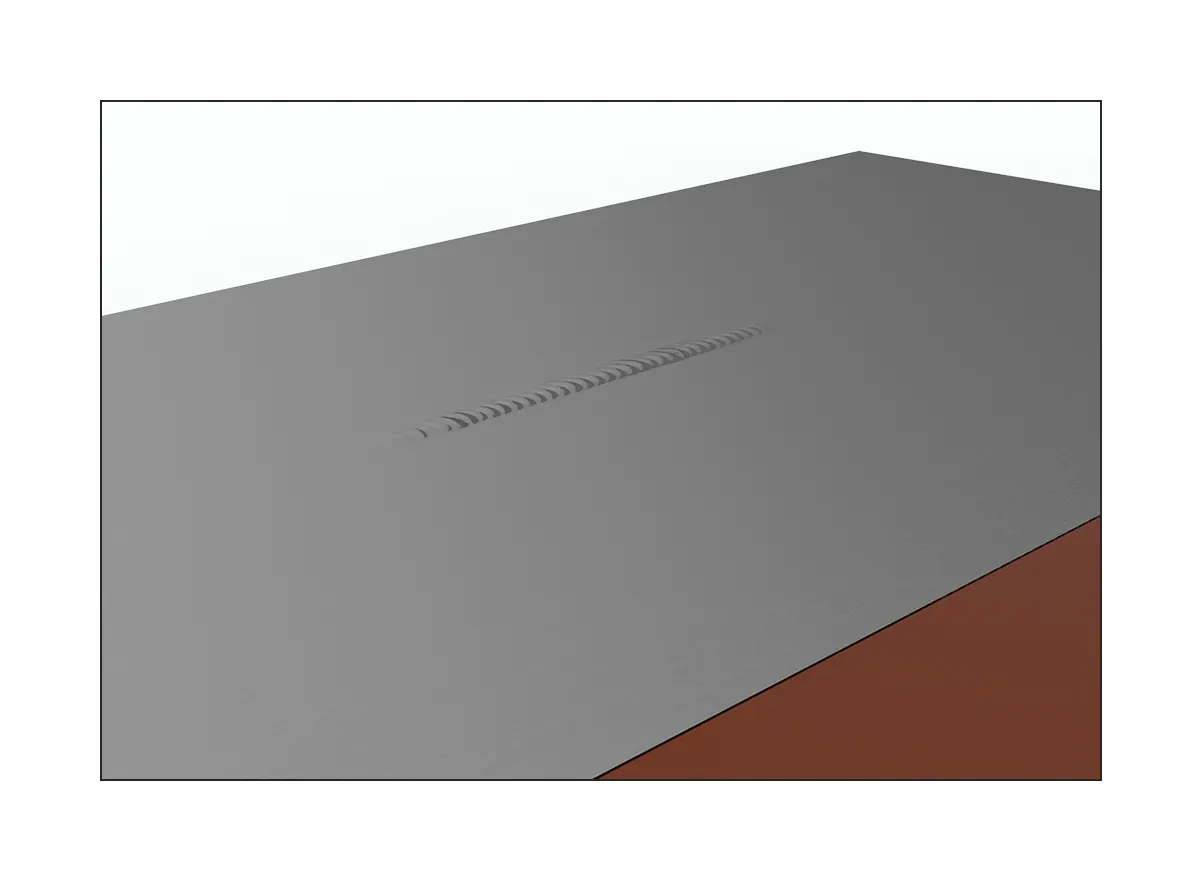

The welding seam is smooth, with negligible distortion allowing users to save time on polishing. A flexible welding machine supports different welding joint types which ensure the precise welding of different materials with the suitability to perform bi-metal welding, joining complex shapes and contours.

Laser Welding provides stronger weld joint strength than traditional welding methods. The portability of Hertz allows the machine to flexibly create strong welding joints on components of different shapes and sizes.

With hertz forget the deformation of the components, as the HAZ area (Heat-affected zone) is very small to keep the physical structure of the materials intact. Not just this, this robust machine is best suited for consistent weld quality for a longer period of time.

The welding can be done in a quicker time, compared to all the conventional welding methods which ultimately increases the production on a mass level in a lesser time.

The HAZ (heat-affected zone) with fiber laser welding is too less compared to all the available welding solutions in the market now.

| Specification | Units | |||

|---|---|---|---|---|

| Power | Watts | 1500 | 2000 | |

| Wave length | nm | 1080 ± 10 | 1080 ± 10 | |

| Mode of operation | Continuos Wave (CW) | Continuos Wave (CW) | ||

| Output Power Tunability | % | 10 – 100 | 10 – 100 | |

| Modulation Frequency | 0 – 5000 Hz | 0 – 5000 Hz | ||

| Power supply | 230 ± 5% VAC, 3 Ø, 50/60 Hz | 230 ± 5% VAC, 3 Ø, 50/60 Hz | ||

| Overall Size (L × B × H) (Approx) | mm | 1300 × 685 × 1200 | 1300 × 685 × 1200 | |

| Weight (Approx) | kg | 150 | 150 | |

| Maximum Power Consumption | kW | 5.5 | 5.5 | |

| Position indication | Red Light | Red Light | ||

| Welding Nozzle Wire Length | mtr | 10 mtr | 10 mtr | |

| Operation Temperature | °C | 10 to 50 | 10 to 50 | |

| *Welding Thickness | mm | Mild Steel: 4 | Stainless Steel: 4 | Aluminum: 2 | Aluminum Alloy: 2 | Galvanized Iron: 2 | ||

| Specification | Units | 1 |

|---|---|---|

| Power | Watts | 2000 |

| Wave length | nm | 1070 ± 10 |

| Mode of operation | Continuos / modulation | |

| Output Power Tunability | % | 10 – 100 |

| Modulation Frequency | 0 – 5000 Hz | |

| Power supply | 230 ± 5% VAC, 3 Ø, 50/60 Hz | |

| Overall Size (L × B × H) (Approx) | mm | 650 × 300 × 621 |

| Weight (Approx) | kg | 70 |

| Maximum Power Consumption | kW | 6.5 |

| Position indication | Red Light | |

| Welding Nozzle Wire Length | mtr | 10 |

| Operation Temperature | °C | 10 to 50 |

| *Welding Thickness | mm | Mild Steel: 4 | Stainless Steel: 4 | Aluminum: 2 | Aluminum Alloy: 2 | Galvanized Iron: 2 |

*The table above indicastes a thickness with a maximum penetration capacity of 2000 Watts

Support

Online Service Response 100%

Physical Response

Delighted Customers

Interested In a Product?

Pricing, Technical Data & More

World’s best high speed fiber laser forming machines with precise and accurate processing for all your business requirements such as metal sheet cutting, welding, cleaning, marking etc.

Ever since incorporation, we have been making our own way through futuristic technology and ground-breaking innovations.

Explore our blogs for a resourceful insight into the infinite opportunities of the laser world.

SLTL Group is the company that has defined what is called a "Trailblazer".

We may be fascinated by the importance of laser today as we are surrounded by things which are a by-product of laser application.

One of the important laser system designed to perform specialized tasks for TOOLTECH industry is SLTL Group’s NOVA. It is capable for welding very small parts and fine structures to larger ones. Achieving strong, visually flawless seams is increasingly important in all production processes.

24*7 service support and technical assistance. You’re welcome to visit our office for other insights

E-30, Electronic Estate, G. I. D. C.,

Sector - 26, Gandhinagar - 382 028

Gujarat, India.