Step into the era of Industry 4.0 with AI- and IoT-powered laser cutting machines that redefine precision and productivity. Smart, connected, and efficient, these systems cut costs, save time, and future-proof your manufacturing operations.

Introduction: The Rise of Smart Manufacturing

The manufacturing industry is undergoing a revolution, commonly referred to as Industry 4.0 – the era of smart factories and intelligent production. Traditional manufacturing processes are being replaced with connected, data-driven, and automated solutions that make production faster, more efficient, and more sustainable.

At the heart of this transformation are laser cutting machines. These machines are no longer just tools for cutting metal; they are now integrated with AI (Artificial Intelligence) and IoT (Internet of Things) technologies that turn them into smart, connected systems. By leveraging these innovations, businesses can not only produce better-quality products but also achieve more efficient and cost-effective operations.

- Industry 4.0 adoption is driving the demand for smarter machines.

- Laser cutting machines play a key role in digital manufacturing ecosystems.

- AI and IoT make laser systems more predictive, productive, and reliable.

2. Why Choose a Laser Cutting Machine for Smart Manufacturing

When it comes to precision metal fabrication, laser cutting machines stand out as the preferred choice for modern manufacturers. Unlike mechanical cutting methods, laser cutting is contactless, meaning there is minimal wear and tear, ensuring long-term efficiency.

Precision and Efficiency Benefits

Laser cutting provides unmatched accuracy, delivering clean, burr-free edges even in complex geometries. For industries like automotive, aerospace, electronics, and sheet metal fabrication, precision is everything – and lasers deliver just that.

- High-quality cuts with no secondary finishing required.

- Faster cutting speed compared to plasma or mechanical cutting.

- Ability to cut intricate shapes and designs with minimal material waste.

Sheet Metal and Metal Laser Cutting Machines

Today’s factories rely heavily on sheet metal laser cutting machines for producing everything from enclosures to machine parts. Metal laser cutting machines can handle a wide variety of materials including mild steel, stainless steel, aluminum, and brass, making them versatile for multiple applications.

- Sheet metal laser cutting machines are ideal for flat components.

- 3D metal laser cutting machines handle tubes, pipes, and profiles.

- Automated systems reduce manual intervention and increase productivity.

Automation Saves Time and Reduces Costs

Modern laser machines come with automated loading/unloading systems, nesting software for material optimization, and integrated fume extraction. This means manufacturers save time, reduce material wastage, and improve operator safety.

- Automation improves machine uptime and production output.

- Lower labor dependency leads to reduced operational costs.

- Smart nesting algorithms reduce scrap and increase ROI.

3. IoT in Laser Cutting Machines

The Internet of Things (IoT) has completely changed how we interact with machines. In the case of laser cutting machines, IoT enables connectivity between the machine, operator, and management systems. This allows for real-time monitoring, remote diagnostics, and performance analytics.

Real-Time Monitoring & Predictive Maintenance

IoT sensors continuously collect data on machine performance, temperature, laser source health, and power usage. This data helps predict when maintenance is required, preventing unexpected breakdowns and reducing downtime.

- Monitor productivity KPIs in real time.

- Get alerts when components need servicing.

- Minimize costly unplanned shutdowns.

Remote Operation & Connectivity

IoT-enabled machines allow supervisors and operators to monitor production remotely via mobile apps or dashboards. This is especially beneficial for multi-factory operations where managers need visibility across multiple sites.

- Remote diagnostics reduce service response time.

- Operators can adjust parameters without being on-site.

- Cloud data storage enables long-term performance tracking.

Benefits of IoT in Laser Cutting

- Reduced downtime through predictive analytics.

- Better machine health via continuous monitoring.

- Optimized production with data-driven insights.

4. AI in Laser Cutting Machines

Artificial Intelligence is the next big leap in manufacturing, and AI-powered laser cutting machines are becoming the new standard.

AI-Driven Cutting Optimization

AI algorithms automatically select the best cutting path, speed, and power settings for each job, reducing cycle time and increasing efficiency.

- AI reduces trial-and-error during machine setup.

- Optimal paths lead to faster cutting and lower energy usage.

- Improved consistency in cut quality across batches.

Reducing Human Error

By automating parameter selection, AI minimizes the risk of incorrect settings that can lead to scrap or rework. This not only saves costs but also ensures a higher first-pass yield.

- Less operator dependency improves consistency.

- AI-assisted controls make machines easier to use.

Data Analytics and Continuous Improvement

AI-driven analytics help manufacturers identify bottlenecks, analyze machine performance, and plan capacity more effectively.

- Historical data supports better decision-making.

- Quality issues can be traced and prevented in future production.

5. How to Choose the Right Laser Cutting Machine

Selecting the right laser cutting machine is crucial for achieving production goals and maximizing ROI.

Factors Affecting Laser Cutting Machine Price

When researching laser cutting machine price, consider these key factors:

- Laser power – Higher wattage machines cut thicker materials but cost more.

- Work area size – Large-format machines handle bigger sheets but require more floor space.

- Automation level – Machines with auto-loading and IoT/AI features are more expensive but boost efficiency.

- Brand reputation – Established brands may cost more but offer better reliability and service.

2D vs. 3D Laser Cutting Machines

- 2D Sheet Metal Laser Cutting Machines: Perfect for flat metal sheets, enclosures, panels, and brackets.

- 3D Metal Laser Cutting Machines: Best for complex structures, pipes, tubes, and custom components.

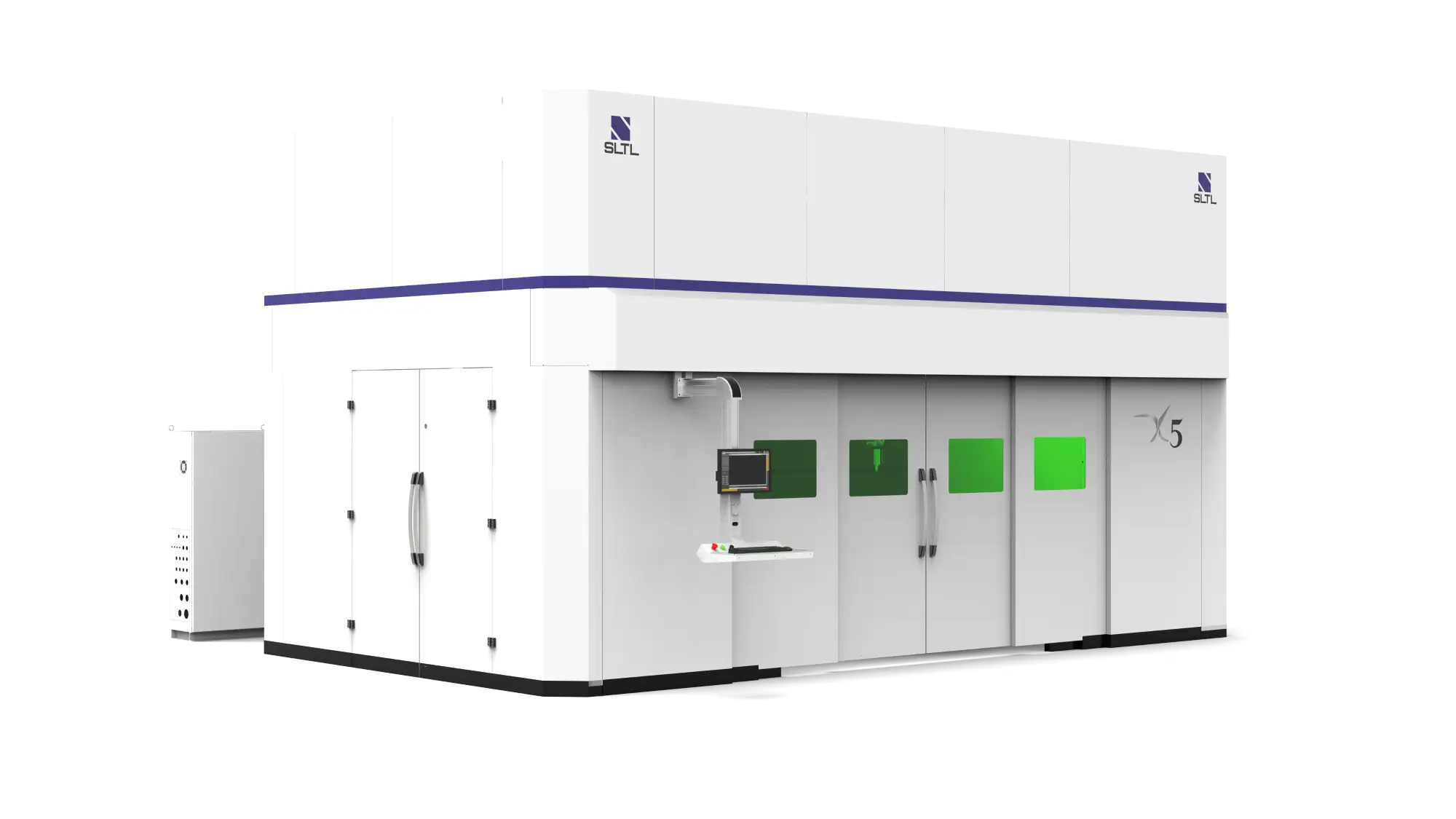

3D Laser Cutting Machine – X5

Power: 1 kW – 4 kW

Material: Mild steel, Stainless steel, Aluminum, Brass, Copper, Galvanized Iron, Coated Sheet, Others.

Explore More – 3D Laser Cutting Machine

Importance of a Trusted Supplier

Buying from a reputable supplier ensures you get a machine that matches your production needs, along with reliable after-sales service and spare parts availability.

- Look for a supplier that offers installation, training, and technical support.

- Ensure they provide IoT-enabled and AI-ready systems for future scalability.

- Check customer reviews and case studies before making a purchase.

6. Where to Buy Laser Cutting Machines

Purchasing a laser cutting machine is a long-term investment, so choosing the right vendor is crucial.

Look for suppliers who:

- Offer a full range of metal laser cutting machines with various power configurations.

- Provide transparent pricing and help you understand laser cutting machine price based on your needs.

- Support customization, automation integration, and smart manufacturing upgrades.

- Deliver training and onboarding to help your team get up to speed quickly.

- Have a strong after-sales service network with quick response time.

Pro Tip: Buy laser cutting machine from a trusted brand that offers installation, operator training, and round-the-clock technical support. This ensures maximum uptime and efficiency for your operations.

7. Conclusion

Smart manufacturing is not a distant dream anymore – it’s here, and it’s transforming industries across the globe. Laser cutting machines with AI and IoT integration are enabling manufacturers to work smarter, cut costs, and deliver precision-engineered products at scale.

If you are looking to stay ahead in the competitive manufacturing landscape, it’s time to buy laser cutting machine that is designed for Industry 4.0. By investing in the right technology, you can future-proof your production, improve efficiency, and meet your customers’ demands with confidence.

- Embrace AI and IoT to unlock higher productivity.

- Choose the right machine based on power, size, and automation needs.

- Partner with a trusted supplier to ensure smooth installation, training, and service.

✅ Ready to make the shift to smart manufacturing? Explore high-performance sheet metal laser cutting machines today and take your production to the next level.