Why Today’s Metal Fabricators Cannot Afford Quality Fluctuations

In the metal fabrication and manufacturing industry, cutting quality is not just a technical detail – it is the foundation of your brand’s reputation. Whether you fabricate for automotive, machinery, construction, consumer goods, industrial equipment, or OEM supply chains, your customers judge you by one thing:

👉 “Do your parts meet the requirement consistently?”

Not once.

Not twice.

But every single time.

Yet for many fabrication shops, cutting inconsistency remains the biggest hidden threat to growth. It silently damages trust, increases costs, slows production, and eventually pushes customers toward other vendors.

We uncover how inconsistent cutting quality destroys your brand reputation, why it happens, and how modern manufacturers are solving it.

Inconsistent Cutting = Slow Delivery Time and Missed Deadlines

Your cutting quality directly impacts how fast you deliver finished parts. Here’s why:

When cuts are inaccurate:

- Assemblies don’t fit

- Holes need resizing

- Edges need grinding

- Sheets need rework

- Parts must be re-run

This instantly adds hours or days to your lead time.

Customer impact:

Late delivery → delayed assembly → production line stoppage → financial loss

Brand impact:

Customers lose trust and start thinking:

“This vendor cannot deliver on time.”

In an industry where supply chains are time-sensitive, even a single delayed shipment can move your customer to a competitor.

High Rejection Rate: The Silent Reputation Killer

Rejection rate is the most painful consequence of inconsistent cutting. Old machines, manual methods, and inaccurate processes often lead to:

- Burrs and rough edges

- Incorrect dimensions

- Wrong kerf width

- Distorted shapes

- Heat-damaged surfaces

- Out-of-tolerance cuts

Even a 3–5% rejection rate can severely hit your bottom line – but the bigger problem?

Customers notice every rejected part.

You may re-cut the sheet and meet the deadline, but the customer still remembers:

❌ “They delivered the wrong size last time.”

❌ “Their cutting is unreliable.”

❌ “We always have to double-check their work.”

Those memories shape your brand perception more than anything else.

Poor Accuracy & Finishing Makes Your Product Look Cheap

When your cutting quality is inconsistent, finishing becomes a nightmare:

- Additional grinding

- Manual deburring

- Filing

- Smoothing edges

- Cleaning discoloration or heat marks

These extra steps:

- Increase labor cost

- Increase cycle time

- Reduce uniformity

- Create inconsistent finishing across batches

This is especially harmful if your customers use the components in visible products (furniture, signage, enclosures, stainless steel items, consumer goods).

If your parts look inconsistent, customers assume your entire operation is low-quality – even when it’s only the cutting phase that is the culprit.

Too Much Rework Damages Efficiency & Morale

Rework is expensive.

When cuts are inconsistent, you end up:

- Re-running the part

- Using new sheets

- Scrapping material

- Assigning extra operators

- Slowing down the entire line

Every rework cycle increases cost and delays the next job. If your team constantly handles rework, morale drops:

“Why do we keep fixing the same issues?”

“We waste so much time on bad cuts.”

“Machines are old and unpredictable.”

This frustration affects productivity and leads to greater human errors – further damaging cutting consistency.

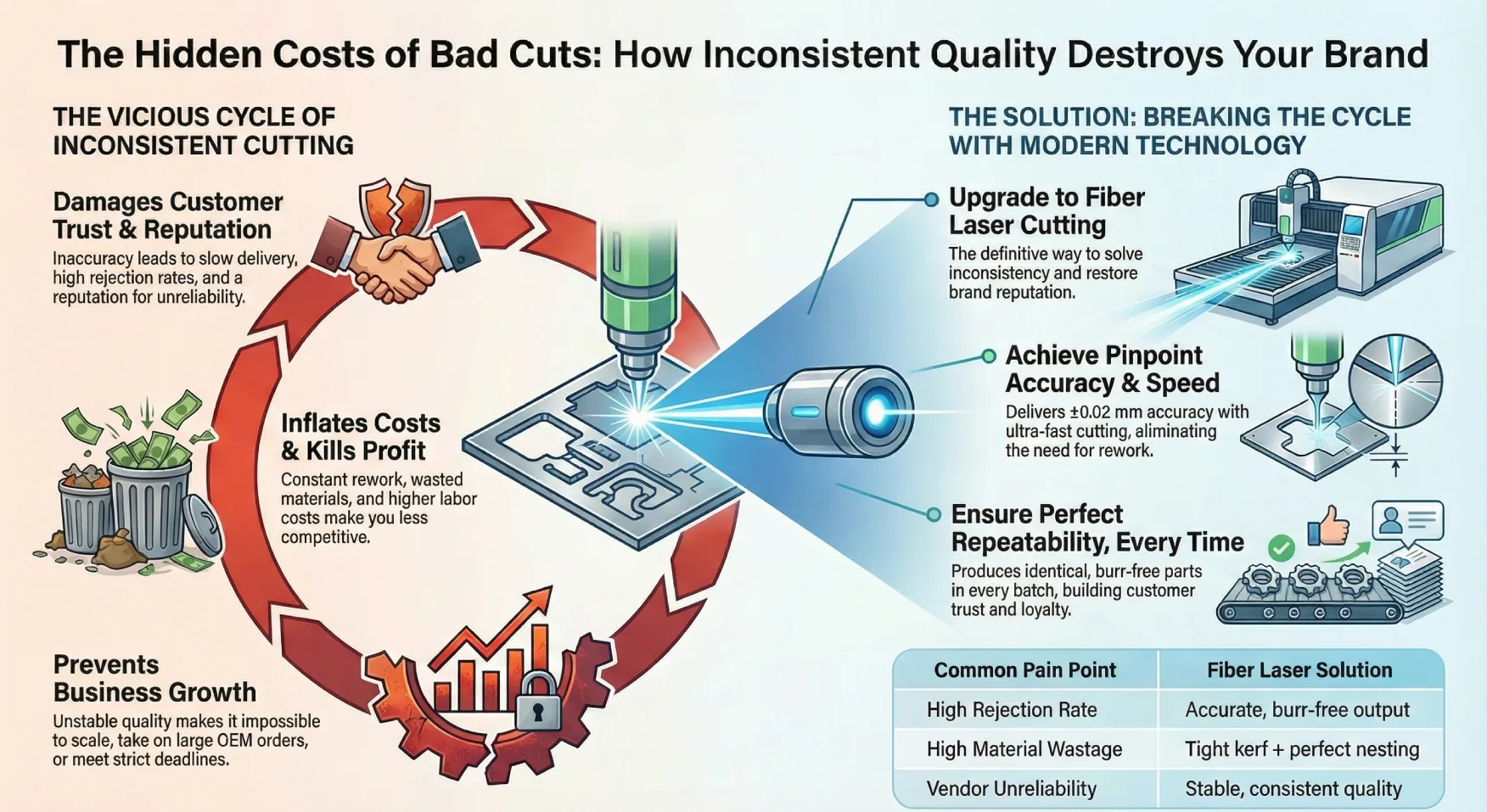

Unpredictable Quality Pushes Customers to Competitors

One batch is good.

Next batch is bad.

Next batch is okay.

This inconsistency forces your customers to constantly inspect your work, sometimes 100% inspection, which increases their internal cost.

Eventually they say:

“We need a stable vendor.”

Unpredictable quality is why many metal fabricators lose long-term contracts – even if their price is competitive.

Your reputation becomes:

❌ Cheap vendor

❌ Time-consuming vendor

❌ High-risk vendor

❌ Not consistent

A brand built over years can collapse over repeated quality fluctuations.

Material Wastage Eats Profit – and Customers Notice It

Material wastage due to poor cutting quality is extremely expensive, especially with high-cost metals:

- Stainless steel

- Aluminium

- Copper

- Brass

- High-tensile steel

When cutting quality is inconsistent, you waste material through:

- Wrong dimensions

- Misalignment

- Excess kerf

- Burning

- Warping

- Rework repetition

Customers eventually notice:

🔹 Higher quotes

🔹 Higher lead times

🔹 Difficulty meeting volume

This gives competitors an advantage because:

Better cutting = lower cost = better pricing.

If your costs rise due to wastage, you cannot price competitively.

Your brand becomes known for “expensive but low accuracy.”

Skilled Labor Shortage Makes Consistency Even Harder

Old cutting technologies rely heavily on operator skill:

- Plasma cutting

- Oxy-fuel

- Shearing

- CO₂ laser cutting

- Manual processes

Each operator works differently, so the output varies batch to batch.

Inconsistent human skill = inconsistent cutting.

With the current skilled labor shortage in India and globally, depending on manual skill is no longer sustainable.

Customers don’t care who the operator is – they want consistent parts, always.

If your team can’t provide this, they switch vendors.

Outdated Cutting Technology Cannot Meet Modern Needs

Most inconsistency comes from outdated systems:

- CO₂ laser

- Plasma

- Oxy-fuel

- Mechanical shearing

- Press brake punching

- Manual cutting tools

These machines cause:

- Burnt edges

- Large kerf width

- Poor tolerance

- Warping

- Slow speeds

- Frequent maintenance

- Heat-affected zones

- Rough finishing

Your customer compares your output to competitors using automation + fiber laser cutting, and they instantly notice the difference.

Your brand starts to look outdated.

High Operating Cost Due to Inconsistent Output

When your cutting quality is unstable, your operating cost increases:

- Higher electricity consumption

- More consumables

- More gas usage

- More manpower

- More maintenance

- More scrap

- More rework

- More downtime

Eventually, your pricing becomes high and less competitive.

Customer perception:

“They charge more but don’t provide consistent quality.”

This is the most dangerous combination for a brand.

Trouble Scaling Production Because of Unstable Cutting

If your cutting quality fluctuates, scaling becomes impossible:

- You cannot take bigger orders

- You cannot commit to strict deadlines

- You cannot match OEM standards

- You cannot supply to export markets

- You cannot handle high-volume jobs

Customers see your limitations and hesitate to give you:

- Yearly contracts

- Large production runs

- Critical assemblies

- Precision components

A reputation for being “small-scale” or “unable to scale” can permanently limit your growth.

Vendor Unreliability: The Biggest Complaint Among Customers

Customers stick with vendors they trust.

When your cutting quality is inconsistent, you become:

- Less reliable

- Less predictable

- More difficult to work with

Customers fear:

- Failed audits

- Failed assembly

- Damaged products

- Shipment delays

- Production downtime

Even if you explain the problem, customers only remember:

❌ “Their parts gave us trouble.”

❌ “We cannot depend on them.”

Trust once broken is hard to rebuild.

Poor Documentation & QC Makes Every Problem Worse

Many fabrication shops don’t have:

- Proper QC checklist

- Parameter settings documentation

- Version control

- Inspection system

- Cutting logs

- Technical reports

- Calibration records

Even if you fix the cutting inconsistency, you cannot prove it without documentation.

Big customers (OEMs, enterprises, exporters) require documentation.

If you fail audits, your brand gets immediately disqualified.

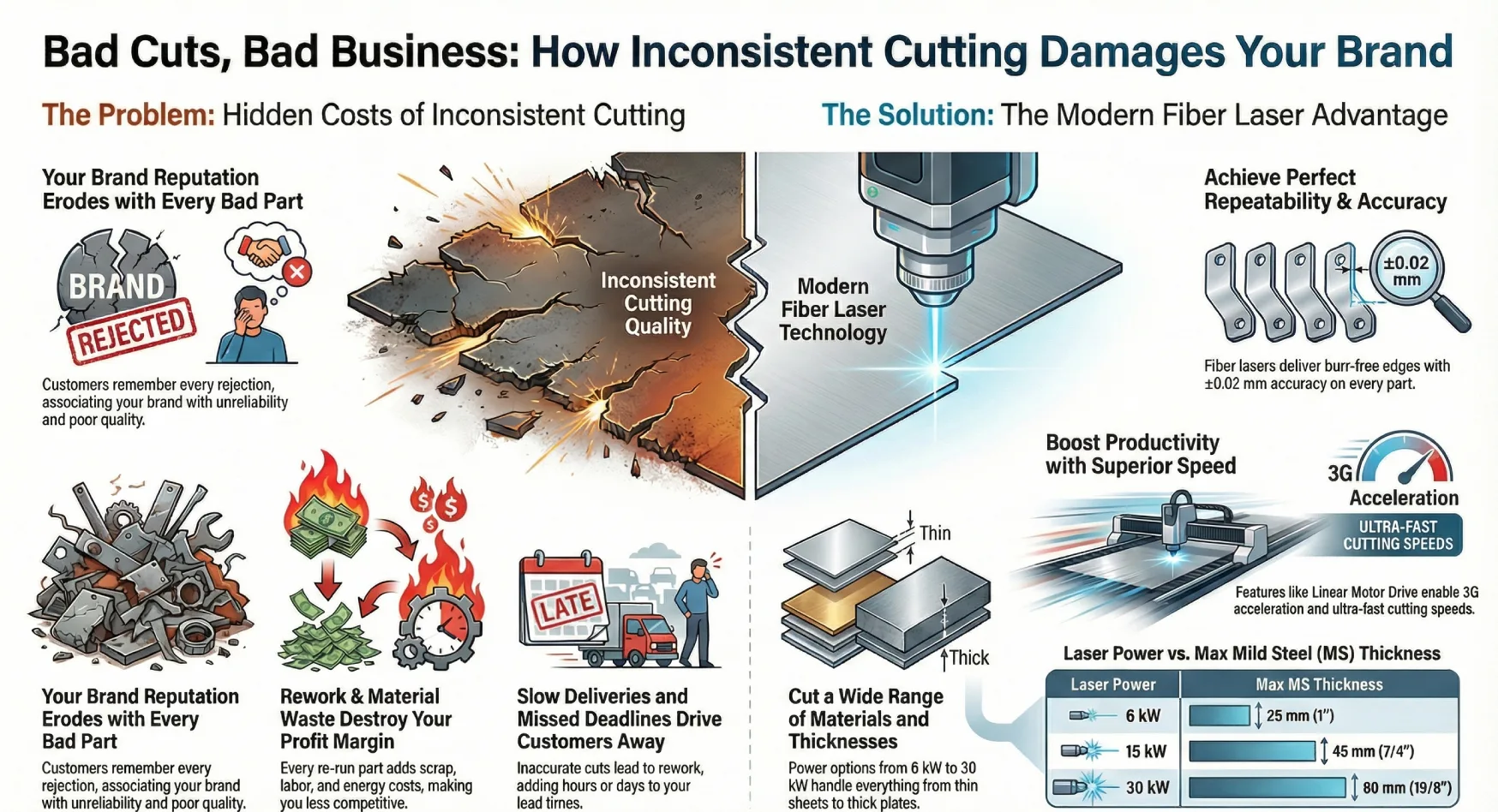

So How Do Leading Fabrication Brands Maintain Consistent Cutting Quality?

The most successful metal fabrication companies today have one thing in common:

They upgraded to modern cutting technology – especially Fiber Laser Cutting.

Fiber laser systems deliver:

- ±0.02 mm accuracy

- Clean burr-free edges

- Ultra-fast cutting speeds

- Low heat input (no warping)

- Zero manual intervention

- Perfect repeatability

- Low operating cost

- Automation compatibility

- Digital presets

- IoT monitoring

This directly solves all customer pain points.

Let’s map the problems to fiber laser solutions:

| Pain Point | Fiber Laser Solution |

| Slow delivery time | Faster cutting + automation |

| High rejection rate | Accurate, burr-free output |

| Poor accuracy | ±0.02 mm repeatability |

| Too much rework | Clean edges, no finishing needed |

| Unpredictable quality | Same result every batch |

| High material wastage | Tight kerf + perfect nesting |

| Labor shortage | Easy operation, auto-focus |

| Old machines | Modern, future-ready tech |

| High cost | Lower electricity + consumables |

| Trouble scaling | Handles high-volume jobs |

| Vendor unreliability | Stable, consistent quality |

| Poor QC | IoT + digital tracking |

Reputation is Everything in Fabrication – Consistency Builds Trust

In the fabrication world, your brand reputation is built on only three things:

- Consistency

- Speed

- Accuracy

If cutting quality is inconsistent, you fail on all three.

Customers won’t tell you this directly, but here is the truth:

💬 “A fabrication vendor is only as good as their cutting machine.”

Upgrading your cutting technology is not just a production decision –

it is a brand decision, a customer trust decision, and a future growth decision.