Sheet cutting rejections rising? It’s not your team, it’s outdated tech hurting accuracy and costing you customers. This blog reveals the real reasons behind failures and how fiber lasers cut rejections by up to 95 percent. Don’t wait until your next batch fails.

Sheet metal fabrication is a business where accuracy, consistency, and finishing quality determine your productivity and your reputation. If your sheet cutting rejection rate is increasing month after month, it’s not just a production issue – it’s a business risk.

Rejected parts cost you:

- Material wastage

- Rework time

- Delay in delivery

- Lost customer trust

- Higher operating expenses

- Team frustration

- Poor brand reputation

Most fabrication owners think the issue is operator skill or material quality, but in reality, 80% of rejections originate from outdated cutting technology.

In this improved blog, we break down the 5 REAL reasons behind rising sheet cutting rejections and exactly how Fiber Laser Cutting solves each one with measurable improvements.

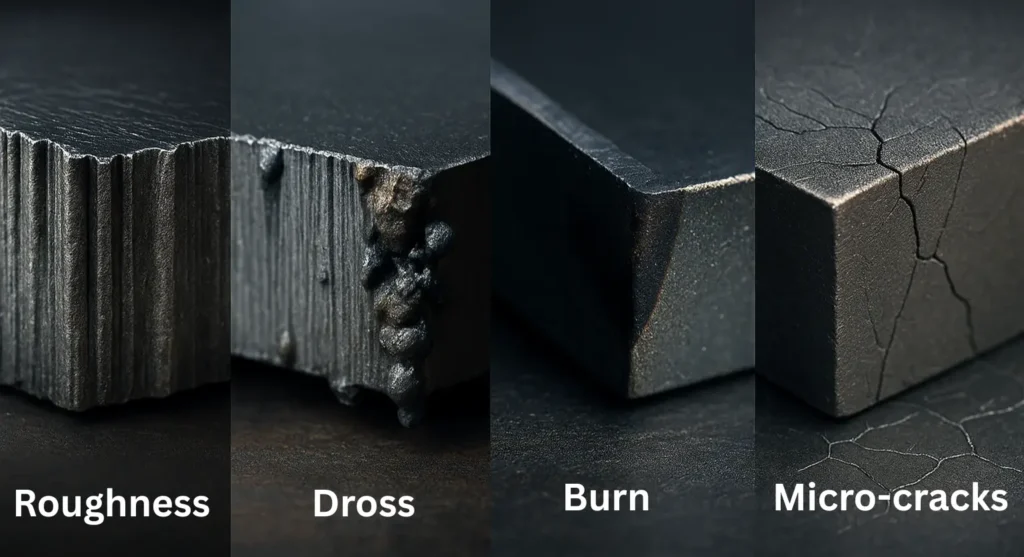

1. Poor Edge Quality – The #1 Reason for Customer Rejections

Why It Happens (Real Factory Scenario)

If your cut parts often look like this:

- Rough edges

- Sharp burrs

- Dross at bottom

- Burn marks

- Micro-cracks

…then your cutting method is failing.

This is common with:

- Plasma

- Oxy-fuel

- CO₂ lasers

- Mechanical shearing

Edge quality suffers because of:

- Excessive heat input

- Unstable flame

- Nozzle wear

- Vibration in mechanical systems

- Manual parameter adjustment

How Fiber Laser Cutting Solves Edge Problems

Fiber lasers deliver clean, burr-free, smooth edges because they use:

- Ultra-focused beam

- Consistent power density

- Extremely narrow kerf

- Low heat-affected zone

Benefits:

- No grinding or finishing

- Zero burr rejection

- High-quality final look

- Perfect assembly fit

2. Dimensional Inaccuracy – Parts Don’t Match Drawings

Why It Happens (Real Factory Scenario)

Fabricators face dimensional errors when:

- Torch height is not stable

- Manual measurement varies

- Kerf width changes during cutting

- Heat causes sheet expansion

- Nozzles wear out

- Older machines vibrate and shift

Industries like automotive, electrical enclosures, HVAC, and machinery reject parts for even 1–2 mm deviation.

How Fiber Laser Cutting Fixes Dimensional Accuracy

Fiber Laser Cutting provides:

- ±0.02 mm precision

- High-speed CNC motion control

- Auto-focus

- Zero vibration

- Stable kerf width

- High repeatability

Outcome:

- Perfect hole sizes

- Precise contours

- No need for resizing

- Same accuracy in every batch

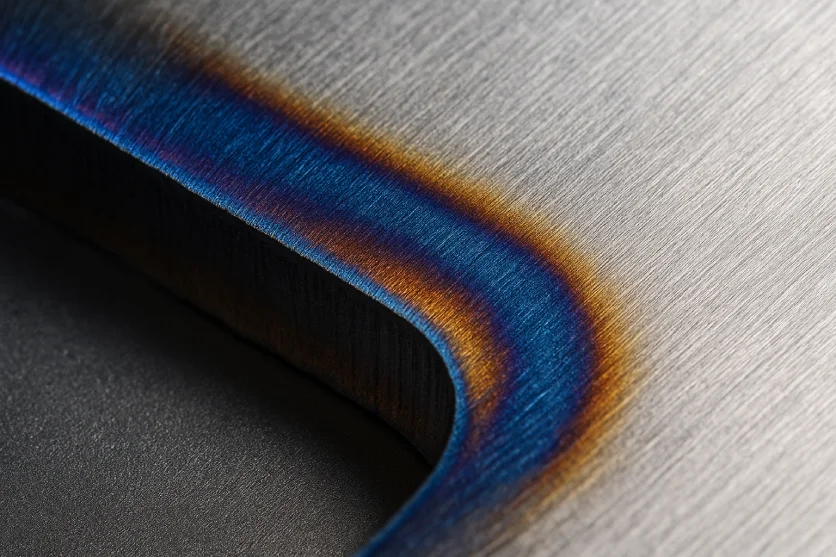

3. Heat Distortion & Warping – A Serious Production Killer

Why It Happens (Real Factory Scenario)

Older cutting systems generate huge heat zones, causing:

- Sheet bending

- Corner deformation

- Color distortion

- Warped edges

- Loss of structural integrity

Materials most affected:

- Stainless steel

- Aluminium

- Thin mild steel

- GI sheets

Warped sheets fail assembly and are instantly rejected.

How Fiber Laser Cutting Prevents Heat Damage

Fiber Laser has:

- Ultra-low heat input

- Minimal heat-affected zone (HAZ)

- Faster cutting that reduces thermal spread

Benefits:

- No warping

- Flat, accurate sheets

- No bending corrections

- No hardness loss

Fiber laser keeps sheets dimensionally stable throughout the process.

4. Inconsistent Output Due to Skilled Labor Dependency

Why It Happens (Real Factory Scenario)

Traditional cutting depends heavily on operator skills:

- Incorrect settings

- Wrong focus

- Variations between shifts

- Human error

- Fatigue

This causes:

- Unpredictable quality

- Random rejections

- Inconsistent finishing

How Fiber Laser Cutting Eliminates Human Dependency

Fiber lasers are designed for automation and repeatability:

- Pre-programmed parameter library

- Auto focus

- Automated piercing

- IoT-based monitoring

- Digital process control

Benefits:

- Same quality every day

- Any operator can run it

- Zero manual adjustments

- Reliable production with minimal skill dependency

5. Material Wastage Due to Poor Nesting + Large Kerf Width

Why It Happens (Real Factory Scenario)

Older cutting methods have:

- Wide kerf

- Poor accuracy

- Inability to cut small shapes

- Bad nesting output

This leads to:

- High scrap

- More sheets consumption

- Frequent re-cuts

- Higher job cost

With rising material prices, wastage directly impacts profitability.

How Fiber Laser Cutting Maximizes Material Utilization

Fiber Laser Cutting provides:

- Ultra-narrow kerf

- Intelligent CNC nesting software

- Precise path control

- Ability to cut complex shapes

Benefits:

- Up to 15–20% raw material savings

- Better sheet utilization

- Fewer reworks

- Less scrap

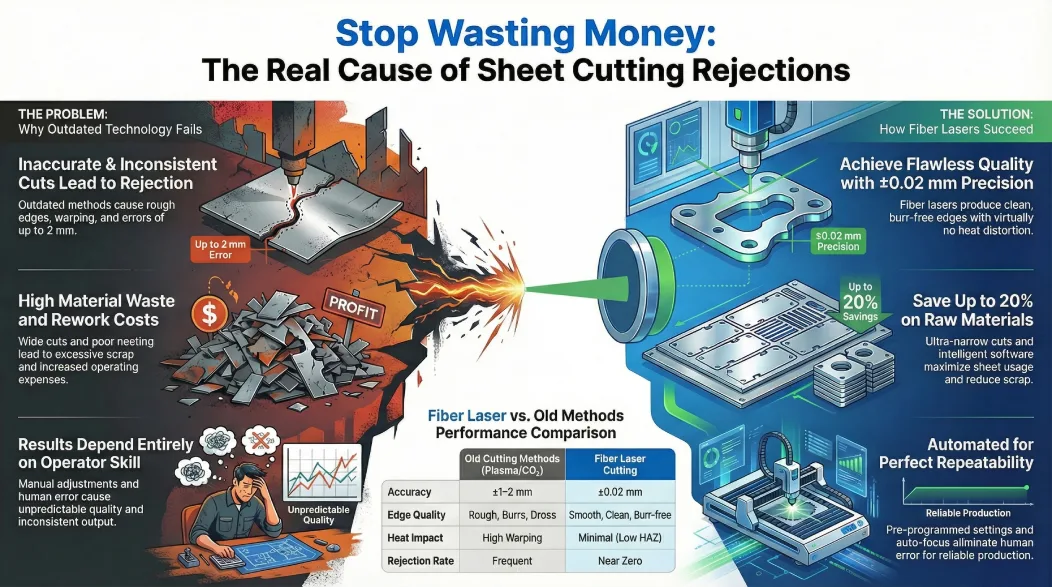

Comparison: Old Cutting Methods vs Fiber Laser Cutting

| Factor | Old Cutting (Plasma/Shearing/CO₂) | Fiber Laser Cutting |

|---|---|---|

| Edge Quality | Burrs, dross, rough | Burr-free, smooth, clean |

| Accuracy | ±1–2 mm | ±0.02 mm |

| Heat Impact | High warping | Very low HAZ |

| Operator Skill | High dependency | Very low |

| Kerf Width | Wide | Ultra-narrow |

| Speed | Slow–medium | 3x–6x faster |

| Scrap | High | Low |

| Rejection Rate | Frequent | Near zero |

| Operating Cost | High gas + consumables | Low operating cost |

| Repeatability | Unstable | Perfect repeatability |

Summary: How Fiber Laser Cutting Dramatically Reduces Rejection Rates

Fiber Laser Advantages at a Glance

- ✔ ±0.02 mm accuracy

- ✔ Clean, burr-free edges

- ✔ Small heat-affected zone

- ✔ 3–6X faster cutting

- ✔ Auto-focus for consistency

- ✔ Zero vibration

- ✔ Low consumable cost

- ✔ Reduced material wastage

- ✔ Excellent repeatability

- ✔ Automation-ready

Direct Impact on Rejection Reduction

- 80–95% fewer burr-related rejections

- 60–90% fewer dimensional rejections

- 50–70% scrap reduction

- Zero warping on thin materials

- Zero operator-related inconsistency

Fiber laser makes your entire production accurate, predictable, and profitable.

Final Thoughts: Rejection Rate Is a Symptom – Technology Is the Real Cause

If your sheet cutting rejection rate is increasing every month, it’s not because:

- your workers lack skill

- your material is bad

- your QC team is weak

The real problem is that outdated cutting technology cannot keep up with modern accuracy standards.

Fiber Laser Cutting is not just a machine upgrade –

it is a productivity transformation, a quality guarantee, and a profitability booster.

Want to Know How Much You Can Reduce Your Rejection Rate?

Send us photos/videos of your rejected parts on WhatsApp : +91 9925036495

We will analyze your cutting issue and share a FREE improvement report (no obligation).

Plus, get a FREE demo pass for our live fiber laser cutting showcase.