STEELFAB 2026 Sharjah is where smart manufacturing meets real business needs. SLTL Group is engaging with manufacturers on laser cutting, automation, and smart factories. If you plan to improve productivity and cut costs, this is the place to connect now.

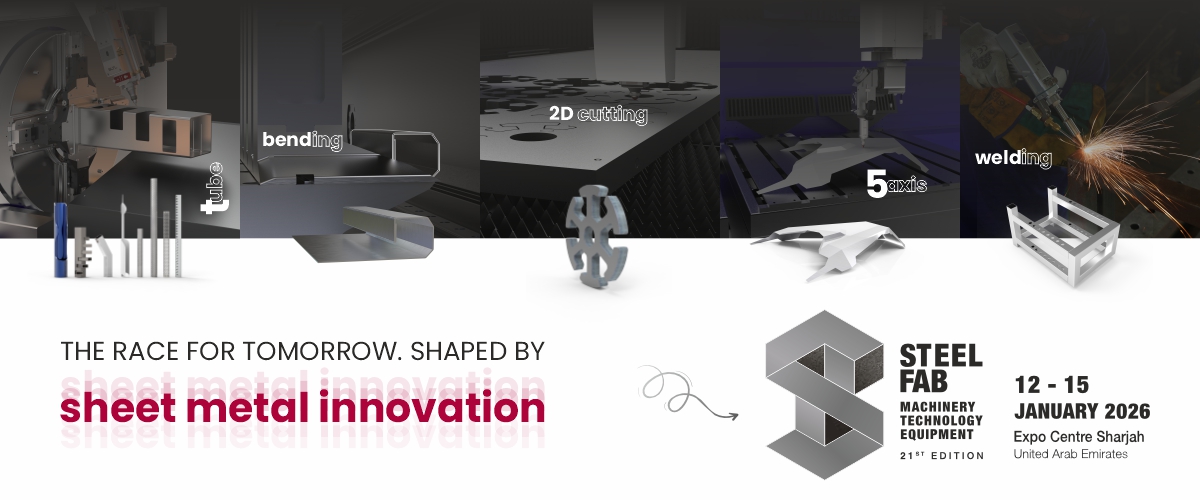

STEELFAB 2026 Sharjah, UAE has long been recognized as the Middle East’s most influential exhibition for metal fabrication, welding, cutting, and industrial manufacturing technologies. Every year, it brings together industry leaders, innovators, decision-makers, and solution providers from across the UAE and the wider GCC region. More than just an exhibition, STEELFAB 2026 Sharjah, UAE is a convergence point where ideas are exchanged, partnerships are formed, and the future of fabrication is actively discussed.

This year, the conversations at SteelFab are more focused than ever on smart manufacturing, automation, and laser-driven production—and that’s exactly where SLTL Group is deeply engaged.

Beyond Booths: Meaningful Conversations on the Show Floor

While SLTL Group is not stationed behind a traditional booth at STEELFAB 2026 Sharjah, UAE, our presence is very much active and purposeful. Our team is walking the show floor, meeting manufacturers, factory owners, and decision-makers, and engaging in discussions that matter.

From fabrication shop owners to large-scale industrial producers, we are connecting with professionals who are exploring how advanced laser technology can transform their operations—making them faster, cleaner, more precise, and more profitable.

SteelFab provides the perfect environment for these one-on-one conversations, where real challenges are discussed and practical, future-ready solutions are explored.

Laser Technology at the Core of Modern Fabrication

Across the UAE and GCC, industries such as metal fabrication, automotive, structural steel, HVAC, and heavy engineering are rapidly evolving. Rising demand for precision, shorter delivery timelines, and cost efficiency is pushing manufacturers to rethink traditional processes.

This is where laser-driven manufacturing plays a pivotal role.

At SteelFab 2026 Sharjah, our discussions revolve around how modern laser systems are redefining industrial production through:

Smart Laser Manufacturing

Laser systems are no longer standalone machines. Today’s manufacturing demands intelligent, connected solutions. Smart laser manufacturing integrates cutting, welding, bending, marking, and automation into a cohesive, data-driven workflow that improves productivity and consistency.

High-Power Fiber Laser Cutting

For thick metal plates and precision fabrication, high-power fiber laser cutting has become a game-changer. It delivers:

- Faster cutting speeds

- Superior edge quality

- Reduced material wastage

- Lower operating costs

These benefits are especially critical for fabrication units handling structural steel, heavy components, and high-volume industrial jobs.

Laser Welding, Marking, Bending & Automation

Modern fabrication demands flexibility, precision, and scalability. Laser welding delivers strong, clean joints with minimal heat distortion, ensuring superior structural integrity. Laser marking enables permanent traceability, compliance, and branding on a wide range of materials. CNC bending systems ensure accurate forming and repeatability for complex components. When these technologies are seamlessly integrated with automation, manufacturers can achieve higher throughput, consistent quality, reduced manual intervention, and scalable production—without compromising precision or reliability.

IoT-Enabled Smart Factories

Smart factories are no longer a future concept, they are becoming a necessity. IoT-enabled laser systems allow real-time monitoring, predictive maintenance, performance analytics, and remote diagnostics. This level of visibility helps manufacturers reduce downtime and optimize operations.

e-Tron Software: Intelligence Behind the Laser

A major focus of our conversations at SteelFab is e-Tron Software, SLTL Group’s proprietary platform designed to enhance accuracy, speed, and efficiency across laser operations.

e-Tron Software empowers manufacturers with:

- Optimized machine performance

- Intelligent job scheduling

- Data-backed decision-making

- Improved throughput and consistency

By combining advanced hardware with intelligent software, manufacturers can unlock the full potential of laser technology.

37+ Years of Laser Innovation Supporting Global Manufacturers

With over 37 years of experience in laser innovation, SLTL Group has been supporting manufacturers worldwide in their journey toward smarter and more sustainable production. Our solutions are designed to help businesses:

- Reduce material waste

- Increase production throughput

- Lower operational costs

- Achieve faster return on investment (ROI)

This global experience allows us to bring proven insights and best practices to manufacturers in the UAE and GCC region.

Let’s Meet at SteelFab Sharjah

If you’re attending SteelFab 2026 Sharjah and exploring ways to:

- Upgrade productivity

- Reduce operational costs

- Implement smart manufacturing

- Future-proof your fabrication setup

We’d be glad to connect.

Let’s meet on the show floor for a quick, focused discussion about how laser technology can support your manufacturing goals.

Reply to this email or write to mkt@sltl.com to schedule a meeting during the exhibition.

Chat with us on WhatsApp for quick coordination.

SteelFab 2026 Sharjah is all about progress, collaboration, and innovation—and we look forward to meaningful conversations and powerful collaborations in Sharjah.

Author Bio

Mayank Patel

R&D HeadMayank Patel is the Head of Research & Development at SLTL Group, bringing over 20+ years of hands-on experience in the field of laser technology. A forward-thinking innovator, he has played a pivotal role in developing advanced laser cutting, welding, and marking solutions tailored for diverse industries. Under his leadership, SLTL’s R&D division continues to push the boundaries of what laser systems can achieve in modern manufacturing.