Bangalore has evolved beyond its title as India’s technology hub; today it stands as one of the most influential manufacturing and engineering ecosystems in the country.

Across Karnataka, industries ranging from heavy fabrication and automotive component production to precision sheet-metal job work and high-value aerospace machining are adopting advanced laser-based solutions at an accelerated pace.

As manufacturers navigate competitive global supply chains, the emphasis has shifted decisively toward technologies that can deliver precision, repeatability, speed, and automation readiness.

With IMTEX approaching, decision-makers across the region are evaluating the next generation of laser systems that not only enhance their operational capacity but also align with long-term digital manufacturing goals.

SLTL Group’s portfolio of fiber laser cutting, 5-axis laser systems, tube processing solutions and marking technologies is recognized as a benchmark in this evolution, offering a combination of technological sophistication and reliability backed by strong regional service support.

Industrial Landscape of Bangalore & Karnataka

Karnataka’s industrial development is marked by a strong presence of large-scale OEMs, MSMEs, and specialized fabrication clusters. Bangalore stands at the core of this growth, supported by well-defined industrial regions that cater to different verticals and production requirements. The state’s manufacturing ecosystem has evolved into a combination of high-volume production units and precision-driven fabrication setups, enabling both local and global supply chains.

Major Industrial Regions of Bangalore

Peenya Industrial Area

- Known as one of Asia’s largest industrial hubs.

- Acts as the backbone of sheet-metal fabrication and job-work activities.

- Home to thousands of MSMEs and large enterprises.

- Key activities include:

- Components manufacturing

- Metal enclosure development

- Structural fabrication

- Custom equipment building

Description: Peenya continues to drive core manufacturing needs with affordable, skilled labor and a wide subcontracting network that supports fast turnaround production.

Bommasandra & Jigani

- Rapidly growing precision fabrication clusters.

- Serve high-demand sectors such as:

- Elevator and escalator manufacturing

- Electrical control panel fabrication

- Commercial kitchen equipment

- Stainless-steel product manufacturing

Description: These regions attract businesses that require clean finishing, precision tolerances, and customized stainless-steel fabrication, making them hotspots for modern cutting solutions.

Whitefield & Electronic City

- Emerging zones fueled by EV, automation, and aerospace industries.

- High need for tight accuracy standards and complex component cutting.

- Growing demand driven by:

- Electronic enclosures

- Aerospace tooling

- Robotic & automation assemblies

Description: Companies in these sectors prioritize precision, consistency, and smarter production technologies, encouraging adoption of advanced laser cutting systems.

Bidadi & Mysore Road

- Preferred location for heavy engineering and automotive suppliers.

- Dominated by thick material processing and multi-shift production lines.

- Reliability and endurance shape purchasing decisions.

Description: Enterprises in these regions need machines capable of long-duty cycles, minimal downtime, and stable performance for demanding applications.

Industrial Growth Beyond Bangalore

- Hubli – Agricultural machinery and farm equipment fabrication.

- Mysore – Growing sheet-metal processing base with small-to-mid workshops.

- Belgaum – Known for steel furniture, machining, and fabrication.

- Mangalore – Focused on port-related manufacturing and marine fabrication.Description: These regions contribute to decentralized growth, enabling Karnataka to build a diverse manufacturing footprint beyond the state capital.

Emerging Trend Across Karnataka

Manufacturers across the state are now viewing fiber laser cutting machines not only as production equipment but as a strategic investment. The shift is driven by:

- Faster delivery capabilities

- Higher precision and repeatability

- Capacity to diversify into premium product segmentsConclusion: Laser cutting solutions are enabling businesses to enhance productivity, reduce lead times, and pursue new market opportunities that were previously out of reach.

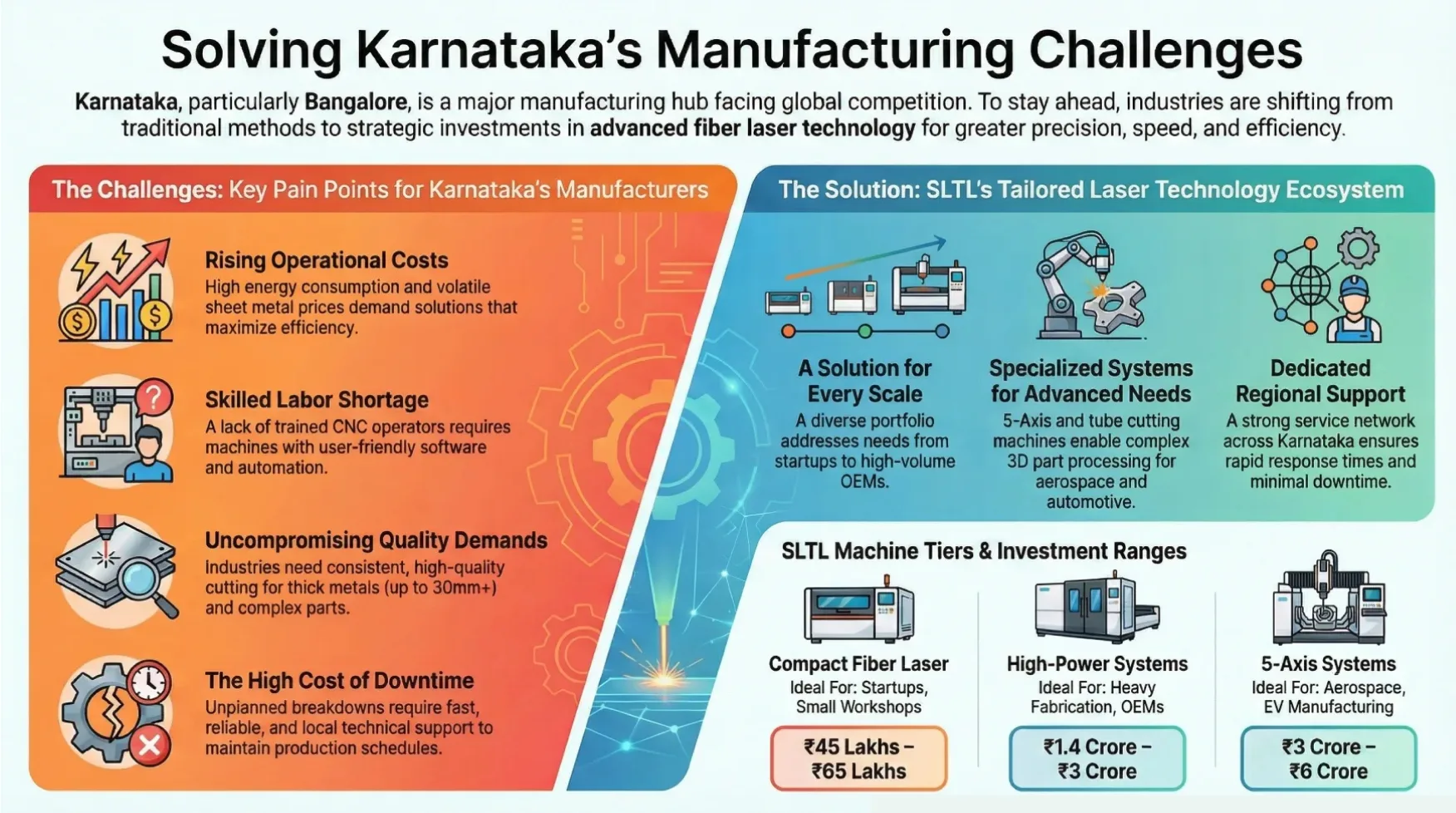

Region-Specific Pain Points Influencing Technology Adoption

- Skilled Labor Challenges

- Shortage of trained operators, especially in Bangalore.

- CNC-trained professionals are expensive and difficult to retain.

- High attrition is a concern for factories running multiple shifts.

- Industries now prefer machines with:

- Automated operations

- Easy-to-use software

- Reduced manual intervention

- High & Unstable Energy Costs

- Factories experience fluctuating electrical loads.

- Old industrial areas lack upgraded power infrastructure.

- Fiber lasers are preferred over CO₂ due to lower power consumption.

- Rising & Volatile Sheet Metal Prices

- Frequent price changes for CRCA, HR, SS304, SS316 materials.

- Manufacturers want solutions that reduce wastage.

- Features increasing demand:

- Intelligent nesting

- Common-line cutting

- Bridge cutting

- Multi-sheet batching

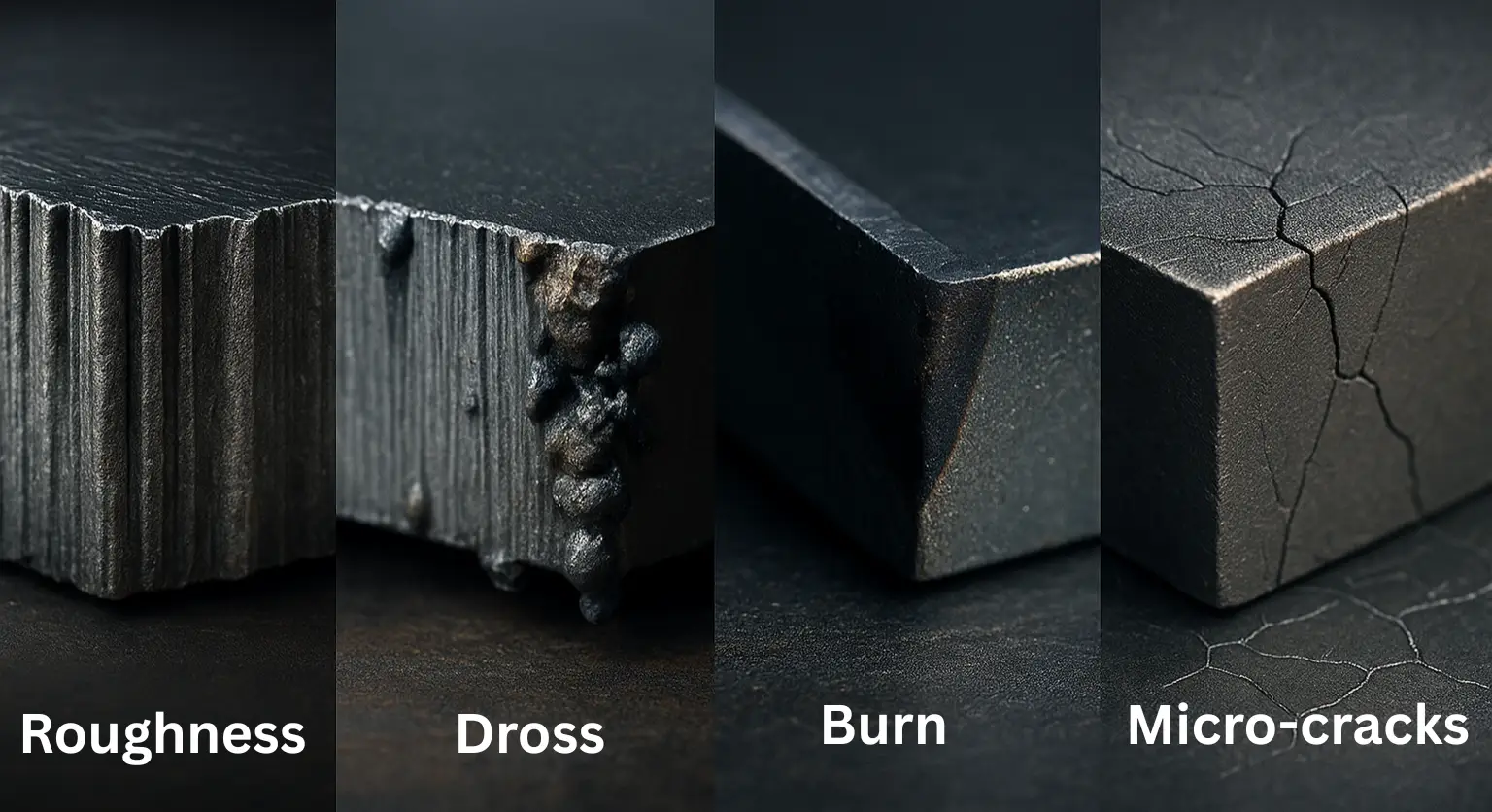

- High Cutting Quality Demand for Thick Metals

- Heavy fabrication in Bangalore needs consistent quality cutting:

- 25-30 mm Mild Steel

- 12-20 mm Stainless Steel

- Traditional methods fail in continuous production.

- Required technology: Fiber lasers with advanced stability and edge control.

- Fast & Reliable Service Support

- Unplanned breakdowns cause direct financial losses.

- Manufacturing clusters like Peenya and Bommasandra demand quick service.

- Preference for companies with:

- Local service engineers

- Quick response teams

- Readily available spare parts

- SLTL has built a strong service network in Karnataka to address this.

Industry-Wise Adoption Trends for Laser Systems in Karnataka

Each industrial sector in Karnataka exhibits unique specifications, tolerances, and material requirements, influencing the type of laser system best suited for their production workflows.

Elevator, Lift & Escalator Manufacturing

This sector relies heavily on consistent accuracy for components such as cabins, landing doors, brackets, and reinforcement structures. Manufacturers in Peenya, Jigani, and Bommasandra require systems capable of processing thin to medium-thick SS sheets with high edge quality. Machines like SLTL IntegreX have become popular due to their compact footprint, rapid cutting speeds, and suitability for moderate production volumes.

General Job-Work & Contract Fabrication

Job-work facilities across Bangalore, Hubli, Mysore, and Belgaum handle diverse materials and thicknesses on a daily basis. Flexibility, ease of programming, and low operational cost are paramount. SLTL’s Prime Series has earned widespread adoption because of its reliability across different sheet types, stable power delivery, and optimized gas consumption.

Heavy Fabrication & Machinery Components

Bidadi-based companies supplying automotive and construction equipment often handle thicker MS plates in continuous shifts. These operations require powerful, highly stable laser systems with precision edge quality and consistent throughput. Machines like Infinity F1 and Vector-designed for high power, structural rigidity, and intelligent thermal control-are favored for such demanding workloads.

Automotive, EV & Aerospace Vendors

These industries require extremely tight tolerances and complex geometries for components such as battery trays, lightweight brackets, heat shields, chassis elements, and precision sheet assemblies. SLTL’s X5 5-Axis Cutting System and high-accuracy 2D systems are particularly suited for these applications due to their advanced motion control, multi-axis flexibility, and 3D part processing capabilities.

Furniture, Interior Fabrication & Architectural Design

Companies dealing with decorative metal panels, facades, modular furniture, and designer installations prefer systems that provide clean cuts and the ability to execute intricate patterns. IntegreX and Prime systems-with high-speed contouring capabilities-deliver precise results for both SS and MS, as well as decorative metals.

Electronics, Control Panels & Electrical Enclosures

Thin-gauge CRCA sheet fabrication requires cutting systems optimized for speed, minimal dross, and repeatability. The Prime series meets these requirements effectively, especially for manufacturers in Electronic City and Whitefield.

Branding, Jewellery & Component Marking

The demand for laser marking in Karnataka has risen sharply due to traceability norms across automotive, electrical, aerospace, and medical sectors. SLTL’s NEO Marking Series offers micron-level detail, making it suitable for intricate engraving, serial numbering, barcoding, and logo marking across various materials.

Laser Cutting & Marking Machine Portfolio – Application-Specific Recommendations

A well-diversified portfolio of laser systems enables manufacturers-ranging from early-stage fabricators to high-capacity OEMs-to select technology that aligns with their cutting volume, material thickness, automation requirements, and long-term capital strategy.

Compact Fiber Laser Cutting Machines

Ideal for: Startups, small fabrication workshops, elevator parts, stainless-steel product manufacturers

These compact systems are engineered for operations working with thin to moderate sheet thicknesses (approx. 0.8-8 mm). Their lightweight motion architecture ensures fast cutting, while simplified controls reduce operator dependency-supporting workshops where labor availability and training are challenges. Energy-efficient components help keep running costs low, making them suitable for businesses operating with tight margins.

Indicative Investment Range: ₹45-65 Lakhs* (varies by power & configuration)

Versatile Mid-Segment Fiber Laser Cutting Machines

Ideal for: Electrical panel manufacturers, job-work units, modular furniture producers, medium-scale fabricators

This segment is preferred by businesses requiring continuous production with flexible material mixes. A reinforced frame and intelligent cutting software ensure consistent cut quality while maximizing sheet utilization. These platforms handle thin to medium-thick materials efficiently, making them a strong fit for companies scaling production without moving to heavy industrial systems.

Indicative Investment Range: ₹65 Lakhs – ₹1.1 Crore*

High-Power Fiber Laser Cutting Systems-Heavy-Duty Production

Ideal for: OEMs, automotive body manufacturers, heavy fabrication clusters, industrial equipment producers

Built for demanding environments, these machines feature rigid structures capable of handling high-power lasers (10-20 kW+) with precision. They excel in thick MS and SS plate cutting (up to and beyond 40 mm), maintaining edge quality even during long cycles. Suitable for manufacturers planning to expand into heavy components or reduce reliance on outsourced thick plate cutting.

Indicative Investment Range: ₹1.4 Crore – ₹3 Crore*

Stability-Driven High-Throughput Cutting Platforms

Ideal for: Multi-shift production lines, automotive sub-assembly, OEM component suppliers

Designed for high-speed volume output, these systems prioritize dimensional stability, thermal control, and automation readiness. Their structure supports future upgrades like automated loading, unloading, and sorting-reducing manual handling and increasing throughput for factories adopting Industry 4.0 practices.

Indicative Investment Range: ₹1.8 Crore – ₹3.5 Crore+*

Tube and Pipe Fiber Laser Cutting Machines

Ideal for: Automotive structures, gym equipment, industrial furniture, architectural metalwork, fabrication clusters

These platforms deliver precision processing for square, round, and rectangular tubes. With stabilized chucking mechanisms and edge control systems, they reduce vibration and post-process grinding needs-improving productivity for businesses manufacturing tubular frames, chassis, and design-driven products.

Indicative Investment Range: ₹1.1 Crore – ₹2.8 Crore*

5-Axis Laser Cutting Systems for Formed & 3D Parts

Ideal for: Automotive, aerospace, EV manufacturing, high-value component producers

These systems offer multi-dimensional trimming, slotting, and profile shaping for complex formed parts that flatbed systems cannot process. Their ability to reduce cycle time and achieve repeatability makes them valuable for precision-driven industries with evolving product designs and tooling limitations.

Indicative Investment Range: ₹3 Crore – ₹6 Crore*

Laser Marking & Traceability Systems

Ideal for: Startups to large scale industries across engineering, consumer products, medical devices, electronic components / branding, serialization, QR codes

Compact, fast, and capable of marking metals and non-metals, these marking units support product identification, traceability, compliance coding, and micro-branding.

Indicative Investment Range: ₹2.5 – ₹8 Lakhs*

Next-Generation Innovations Featured at IMTEX

SLTL’s latest innovations, including Infinity F1, Vector, and NEO Marking, represent significant advancements in precision, speed, and process automation. These systems incorporate intelligent algorithms for beam shaping, dynamic piercing, and quality control, enabling industries to meet increasingly stringent global standards. IMTEX visitors will experience real-time demonstrations that highlight advancements in thermal management, gas optimization, user-interface design, and multi-material processing.

Why Karnataka Manufacturers Prefer SLTL

Manufacturers across Karnataka consistently choose SLTL because the company offers a comprehensive ecosystem-research-backed technology, robust machine design, and dependable regional support. SLTL’s solutions are tailored for Indian industrial conditions, factoring in power fluctuations, multi-shift workloads, and diverse material types. The company’s service structure ensures rapid response times, with experienced engineers positioned across Bangalore, Mysore, Hubli, Belgaum, and Mangalore. This proximity minimizes downtime and ensures that production schedules remain uninterrupted.

Moreover, SLTL’s long-term commitment to innovation provides manufacturers confidence that their investment will remain relevant as technology and application requirements evolve. Integrated automation readiness, upgradeable laser power, and modular machine design offer enterprises the scalability necessary for future expansion.

Why Customers in Karnataka Trust Us

Local Service & Technical Support Infrastructure

SLTL maintains a comprehensive service ecosystem across Karnataka, equipped to provide rapid on-site support, preventive maintenance, operator training, calibration, and software assistance. The company’s strategic presence in Bangalore ensures that industrial zones such as Peenya, Bommasandra, Bidadi, Jigani, and Whitefield receive timely technical intervention. Additional support centers in Mysore, Hubli, Belgaum, and Mangalore enhance coverage for the wider region.

SLTL’s service approach prioritizes minimizing downtime. Engineers are trained to diagnose and resolve issues efficiently, with access to stocked spare parts and remote diagnostics tools. This level of support is a crucial differentiator for enterprises running high-volume production lines where sustained machine availability is essential.

Experience SLTL at IMTEX 2026

IMTEX offers manufacturers a unique opportunity to witness SLTL’s advanced laser cutting, welding, marking, and automation ecosystems in a live, interactive setting. Enterprises attending the exhibition can evaluate cutting-edge technologies firsthand, consult with SLTL’s engineering experts, and understand how each system can be integrated into their existing manufacturing workflows.

Register now to schedule your personalized demonstration at IMTEX 2026 and explore the technologies shaping the future of precision fabrication.

FAQs – Bangalore & Karnataka Manufacturers

- Which machine is suitable for startups in Bangalore?

IntegreX is ideal due to its compact design, cost-effectiveness, and ability to handle diverse cutting requirements with low operational complexity. - Which machine is most suitable for job work in Peenya?

The Prime Series (3-6 kW) is preferred for its versatility, stable performance, and capability to manage varied workloads efficiently. - What is the best solution for thick MS plate cutting?

Infinity F1 and Vector systems are engineered for high-power applications and deliver superior results in thick material processing. - What is the price of a 3 kW fiber laser cutting system in Karnataka?

Prices typically range between ₹45-70 Lakhs depending on configuration and features. - Does SLTL offer operator training in Bangalore?

Yes, SLTL provides on-site training and comprehensive skill-building programs for new operators and technicians. - What is the typical service response time?

Due to SLTL’s service presence across Karnataka, most service requests are addressed within the same day or the next working day. - Are SLTL machines suitable for multi-shift production?

Yes. Systems such as Prime, Infinity F1, and Vector are built with industrial-grade components optimized for continuous, multi-shift environments.