Intelligent Machine Management

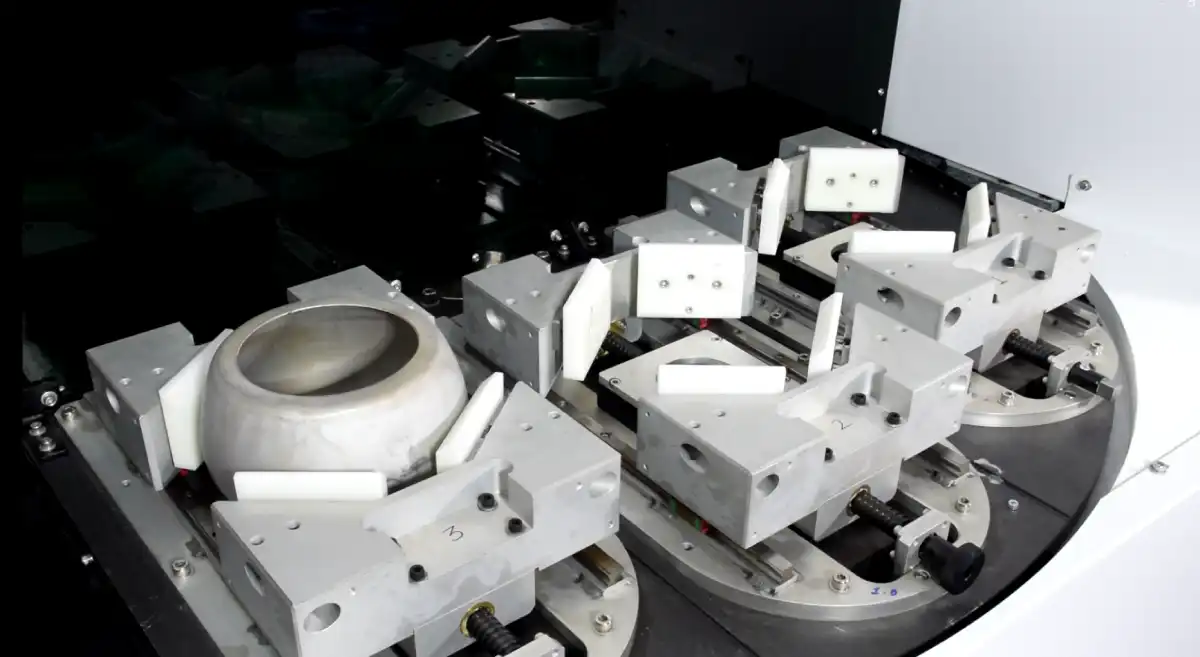

Intelligent Machine Management in IoT plays a big role in how SLTL’s laser cutting machines operate. With IoT-enabled systems, every SLTL machine can be monitored in real time, giving operators detailed insights into performance, workload, and maintenance needs. For example, sensors inside the cutting machines continuously track temperature, power usage, cutting speed, and material quality. This information is sent to a central platform where it can be analyzed instantly. If there’s an issue, like overheating, unusual vibrations, or a drop in accuracy; the system can send immediate alerts, allowing technicians to take preventive action before downtime occurs. This ensures that the machines remain reliable, productive, and cost-efficient, even in demanding industrial environments.

Beyond monitoring, IoT brings automation into play by adjusting machine settings on its own for better efficiency. For instance, SLTL’s cutting machines can automatically optimize cutting paths, control energy usage, and adjust beam focus to deliver high precision without human intervention. Intelligent management also supports predictive maintenance, meaning the system can forecast when a part is likely to fail and suggest replacement before it interrupts production. This saves both time and money while extending the machine’s life. By turning laser cutting machines into “smart” machines, IoT gives SLTL customers the power to run smoother operations, cut down waste, and achieve consistent quality in every cut.