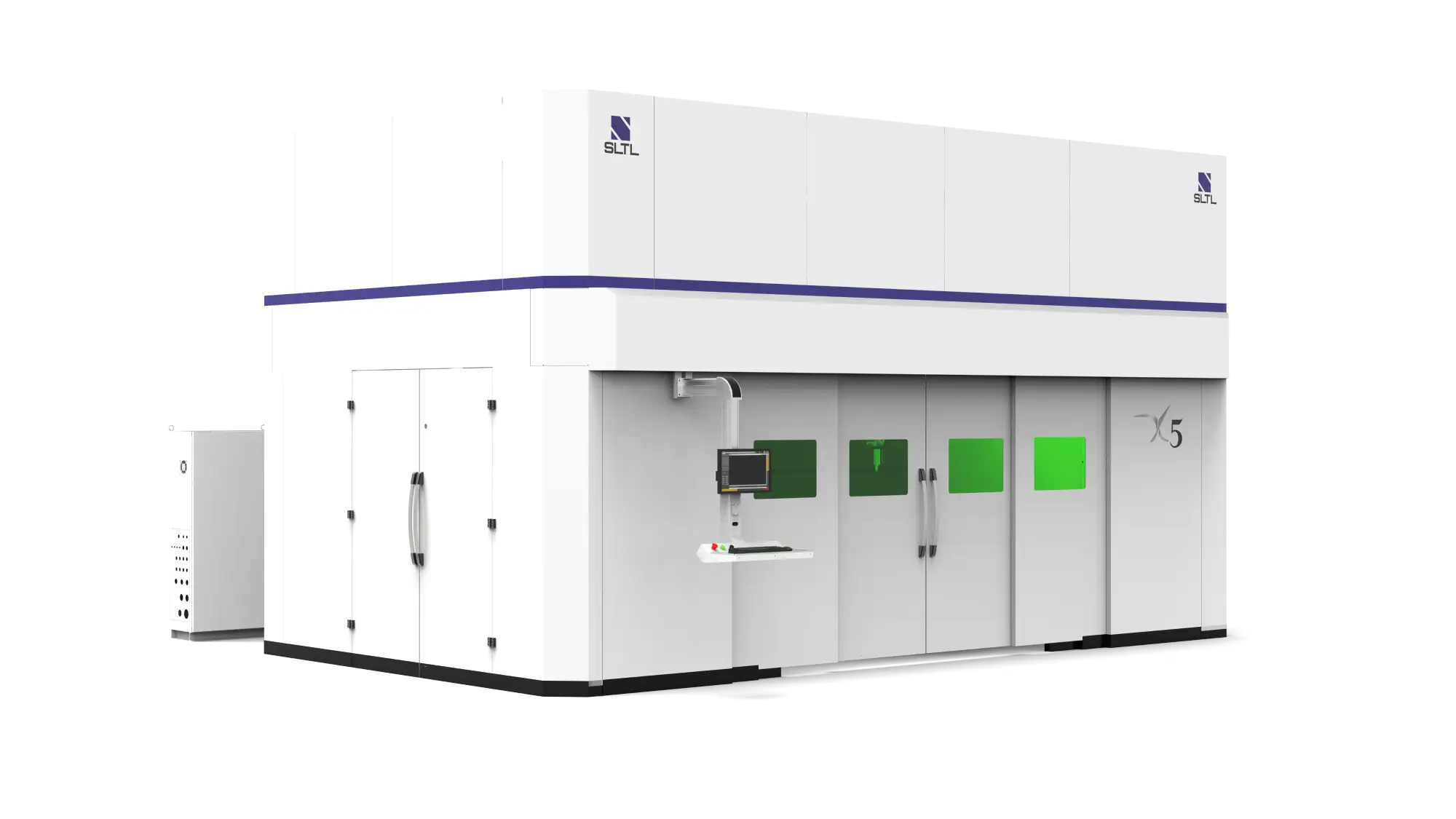

SLTL's X5 5-axis laser cutting machine is designed to cut complex parts quickly and accurately. It works well for industries like automotive and aerospace. It's a smart choice for modern factories.

In the dynamic world of industrial manufacturing, where precision, speed, and adaptability dictate success, SLTL Group has once again raised the bar with its revolutionary 5-axis 3D fiber laser cutting machine – the X5. Designed to address the evolving challenges of modern fabrication, the X5 goes beyond traditional cutting methods to offer a smarter, faster, and more flexible solution for complex components. From automotive sheet metal to aerospace fixtures, the X5 provides the versatility to process intricate geometries with unparalleled accuracy and consistency.

Empowered by True 5-Axis Technology

At the heart of the X5’s innovation lies its 5-axis motion system, which adds the A and C rotational axes to the conventional X, Y, and Z linear movements. This additional freedom of movement allows the machine to cut at virtually any angle, enabling it to reach challenging areas of a part without repositioning or re-clamping. The result is a laser system that can cut three-dimensional contours, inclined surfaces, and uniquely shaped profiles with ease, precision, and repeatability.

3D Laser Cutting Machine – X5

Power: 1 kW – 4 kW

Material: Mild steel, Stainless steel, Aluminum, Brass, Copper, Galvanized Iron, Coated Sheet, Others.

Explore More – 3D Laser Cutting Machine

Engineered for Performance and Precision

The X5 is engineered to deliver exceptional performance across the board. With a maximum speed of 80 m/min on the X and Y axes and acceleration rates of 10 m/s², the machine combines rapid motion with high-level control. The positional accuracy of ±0.1 mm/m and repeatability of ±0.05 mm/m ensure consistent cutting quality, even in demanding applications. The rotational axes – A and C – boast a speed of 720° per second and an impressive ±135° swivel range on the A axis, making it one of the most dynamic laser cutting systems in its class.

Operator-Friendly with Ergonomic Control

One of the most striking features of the X5 is its flexible control panel, which can slide along the length of the machine. This ergonomic design enhances operator convenience, enabling control from either side of the system. This feature is especially useful in high-volume production environments where seamless workflow and minimal intervention are critical. The intuitive interface is complemented by smart automation capabilities, allowing for one-time programming that eliminates the need for manual adjustments during component processing.

Multiple Sizes and Power Configurations

The X5 is available in two formats – 3015 and 4020 – catering to varying workspace and material size requirements. It supports laser power options ranging from 2 kW to 4 kW and can handle a maximum sheet weight of up to 1100 kg. The work envelope extends up to 3550 x 1550 x 650 mm, providing ample space for large and complex components. Whether cutting flat sheets or three-dimensional assemblies, the X5 delivers maximum throughput with minimum downtime.

Smart Factory Ready – Built for Industry 4.0

Driven by the principles of Industry 4.0, the X5 integrates real-time monitoring and process optimization tools. Users gain valuable insights into gas consumption, energy usage, material flow, and machine status, all displayed through an intuitive dashboard. Alerts for maintenance and operational efficiency metrics allow manufacturers to make data-driven decisions, reduce production costs, and extend equipment lifespan. The system also supports multiple assist gases, including Nitrogen, Oxygen, and Air, enabling a broad range of material processing applications.

Optimized for Sustainable and Efficient Cutting

Beyond its technical specifications, the X5 is built for sustainability and energy efficiency. With predefined prime parameters and smart piercing mechanisms, it minimizes gas and power consumption without compromising on quality. The system’s advanced software-hardware synergy facilitates high-speed cutting while ensuring accurate interpolation of all five axes. This makes the X5 ideal for complex jobs that demand precision across varied material thicknesses and contours.

The Ultimate Machine for Complex, Large-Scale Jobs

SLTL’s X5 is more than a cutting machine – it is a strategic investment into the future of manufacturing. Its ability to process oversized parts, intricate profiles, and elevated fixtures makes it a standout choice for industries such as automotive, aerospace, railways, HVAC, and general fabrication. The extended Z-axis reach allows for processing at extreme angles and heights, ensuring that even the most complex jobs can be completed efficiently.

Driven by a Legacy of Innovation and Trust

Supporting this cutting-edge technology is SLTL’s proven commitment to customer satisfaction and service excellence. With over 25,000 installations in 48+ countries, 31+ patents, and 36+ years of industry experience, SLTL Group is recognized globally as an innovation leader in laser technology. Their customer-first approach is reflected in their 98.7% satisfaction rate, rapid <6 hour service response times, and a dedicated support system designed to keep operations running at full capacity.

The X5 – A Future-Ready Investment in Laser Cutting

SLTL’s strong foundation includes six manufacturing plants, a state-of-the-art R&D center, and ISO 9001:2015 certification – all contributing to its reputation for delivering reliable, robust, and technologically advanced systems. The X5 is a testament to this legacy – a machine that brings together engineering brilliance, operational intelligence, and unmatched versatility in one integrated platform.

Conclusion

In conclusion, the SLTL X5 5-Axis 3D Fiber Laser Cutting Machine is a benchmark in advanced laser cutting solutions. It offers limitless flexibility in terms of format, power, and design, enabling manufacturers to meet the ever-increasing demands of precision fabrication. With its cutting-edge features, real-time optimization, and intuitive user experience, the X5 empowers businesses to maximize productivity, reduce operational costs, and achieve superior cutting results across all materials and complexities.

For those looking to future-proof their fabrication capabilities, the X5 is not just a machine – it’s a transformation.

Join our live webinar on 4th July from 3:30 to 4:30 PM GMT+5:30.

Register now: http://sltl.in/web-webinar

Get in Touch – Transform Your Production with SLTL X5

📞 +91-99250 36495

📧 mkt@sltl.com

🌐 www.sltl.com

Sahajanand Laser Technology Ltd. (SLTL Group)

E-30, Electronic Estate, G.I.D.C., Sector-26, Gandhinagar – 382028, Gujarat, India