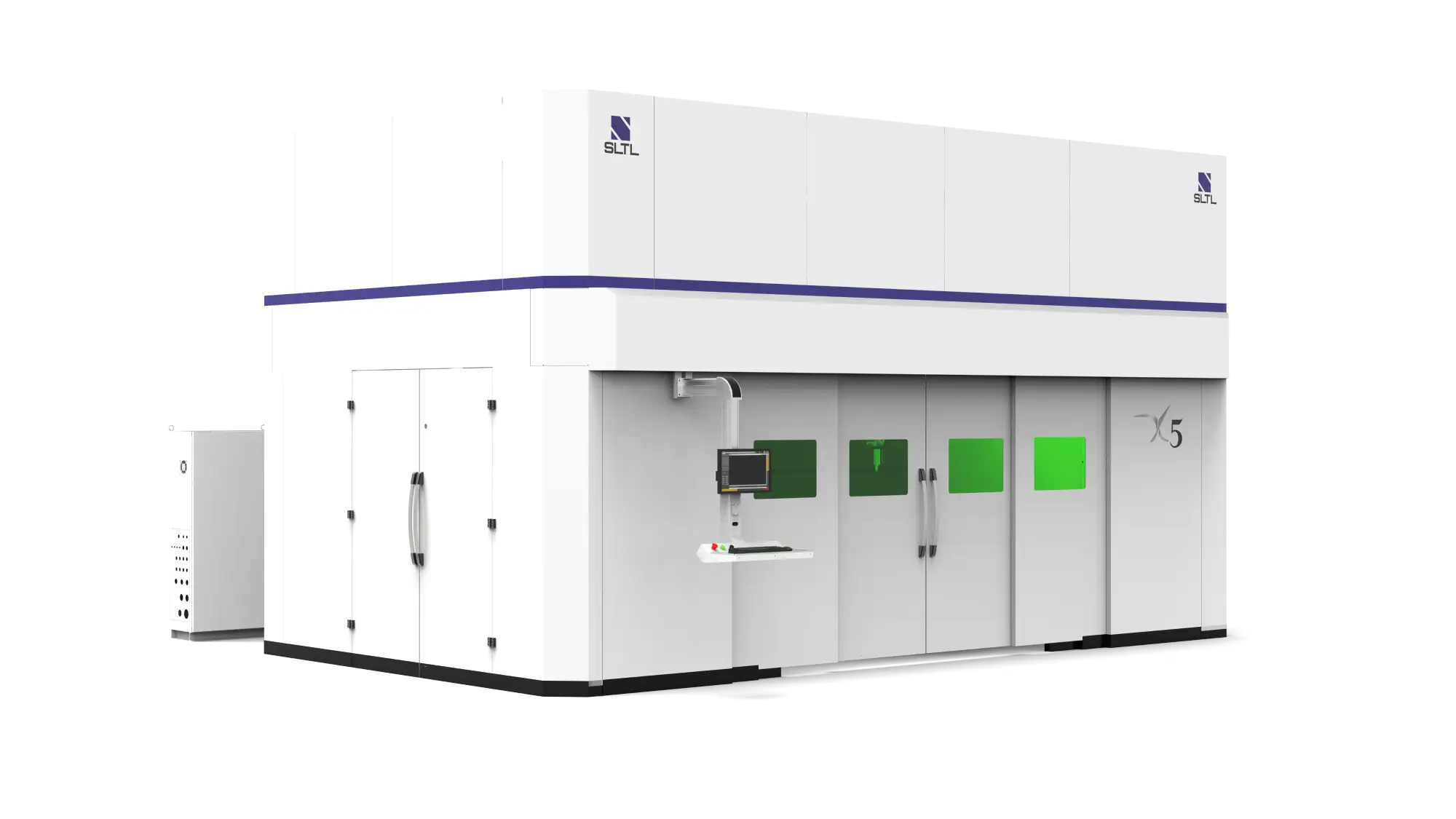

Still relying on outdated cutting methods? SLTL's X5 offers 5-axis precision, faster output, and no rework. Cut complex parts in one go, reduce waste, save labor, and stay ahead in today’s competitive market.

In today’s fast-evolving manufacturing landscape, time, accuracy, and adaptability are no longer luxuries — they’re non-negotiables. Every component you cut, every hour you spend, and every rupee you invest must serve the goal of precision, speed, and smart resource use. Yet, many companies continue to operate with outdated machinery, hoping traditional processes can keep pace with modern demands.

Here’s the reality: they can’t. And the longer you wait, the wider the gap becomes.

Enter the SLTL X5 — a cutting-edge, 5-axis fiber laser machine designed to address not just operational inefficiencies but the strategic future of manufacturing itself.

Are You Cutting With Confidence — or Just Cutting Time?

Think honestly for a moment:

- How often are your jobs delayed due to multiple setups or tooling errors?

- How much material have you scrapped this month due to inaccuracy or rework?

- Are your systems prepared to handle composite or high-performance materials?

- How easily can your setup shift from one complex shape to another — without breaking stride?

If these questions spark even a flicker of doubt, you’re likely operating with invisible losses. Every scrap, every extra operator, every missed deadline is quietly draining your bottom line — and opening the door for your competitors.

The SLTL X5 wasn’t built to compete with traditional machines. It was engineered to replace them. From zero-angle precision to high-speed multi-axis motion, it reinvents what’s possible in laser cutting — turning operational strain into industrial supremacy.

Manufacturing Demands Have Changed. Have You?

Industries like aerospace, defense, automotive, and heavy fabrication are evolving rapidly. Customers demand customization, components are getting more complex, and timelines are becoming tighter. Yet many fabricators still wrestle with:

- Repeated setups that increase lead times

- Dependency on dies, trimming presses, or manual finishing

- Safety issues in high-speed production environments

- Inability to work with advanced materials like FRP and GRP

- Space-consuming machines that reduce shopfloor flexibility

The X5 addresses every one of these challenges through a consolidated, software-driven architecture. One machine. One setup. Multiple operations. And zero compromise on quality.

X5 in Action: The Architecture of Smart Results

Let’s unpack why the SLTL X5 is becoming the backbone of next-gen fabrication shops.

1. Precision, Every Time

With 5-axis motion control (X, Y, Z, A, and C), the X5 brings unparalleled flexibility and accuracy to 3D cutting. Its Tool Center Point (TCP) management ensures consistent zero-angle accuracy — even in difficult contours or large assemblies. Whether it’s a beveled exhaust pipe, an armored panel, or a hydroformed bracket, you get clean, ready-to-assemble results — first time, every time.

2. Speed Without Sacrifice

Exceptional hardware-software synchronization enables brisk cutting without sacrificing precision. Faster piercing, quicker positioning, and intelligent axis control mean shorter cycle times — critical in today’s “need it yesterday” manufacturing world.

Compared to conventional cutting technologies, the X5 can slash production time by up to 30%. That means quicker deliveries, happier clients, and room to take on more business without expanding your workforce.

3. Reduced Labor and Rework

The automation potential of the X5 is transformative. With CNC-controlled consistency and minimal manual intervention, one operator can do the work of many. There’s no need for repeated setups, no need for constant supervision, and no surprise deviations. Fewer errors mean less rework — freeing your team to focus on growth, not corrections.

4. Cost Efficiency Where It Counts

From a financial perspective, the X5 delivers high ROI on multiple fronts:

- Reduced material waste through narrower kerf and optimized nesting

- Lower energy costs due to adaptive power modulation

- Minimal maintenance and no tool wear

- Elimination of dies, trimming presses, and fixture tooling

When you consolidate operations into a single smart setup, costs drop — and margins rise.

3D Laser Cutting Machine – X5

Power: 1 kW – 4 kW

Material: Mild steel, Stainless steel, Aluminum, Brass, Copper, Galvanized Iron, Coated Sheet, Others.

Why This Matters: A Strategic Lens Through PESTEL

The power of the X5 doesn’t just rest in specs — it aligns with broader global and industry shifts. Here’s how:

- Political: As government projects in defense and infrastructure grow, demand for high-grade, precision-cut components is rising. The X5 meets these standards with ease, becoming a go-to choice for mission-critical projects.

- Economic: Global pressures are making efficiency and ROI critical. With the X5, manufacturers cut labor dependence, reduce errors, and speed up production — giving you a cost edge in competitive markets.

- Social: Safety and operational ease matter. The X5’s non-contact cutting and intuitive control interface make it safer for operators and reduce training time.

- Technological: As Industry 4.0 and digital manufacturing become standard, the X5’s scalable software and digital flexibility prepare you for future tasks — without hardware overhauls and is equipped with SLTL Dynamix — Smart IOT platform.

- Environmental: With lower power usage and reduced scrap, the X5 supports sustainable practices, appealing to eco-conscious clients and international ESG standards.

- Legal: Designed with international safety, quality, and operational regulations in mind, the X5 helps future-proof your compliance.

The Machines Are Changing. So Are Your Competitors.

Let’s be blunt. Across India and beyond, smart manufacturers are already upgrading. They’ve seen the writing on the wall: leaner operations, fewer errors, cleaner outputs, and faster changeovers are no longer optional — they’re the price of staying in the game.

Those who’ve switched to the SLTL X5 are seeing:

- Quicker job turnarounds

- Reduced manpower needs

- Consistent, repeatable quality

- The ability to tackle more complex, high-value projects

In sectors like automotive, aerospace, construction, and even renewables, they’re landing bigger orders and outperforming rivals stuck in the old way of cutting.

What Happens If You Wait?

While your team repositions a part for the third time today, someone else is already done with theirs.

While you’re checking if the die has arrived, someone else is digitally loading tomorrow’s job.

While you’re calculating scrap losses, someone else is calculating expansion.

Delay isn’t neutral. It’s dangerous. Every day you hold back on automation, precision, and intelligent integration is a day your competitors get further ahead.

One Setup. Infinite Possibility.

At its core, the SLTL X5 is more than a machine — it’s a strategy. A bridge from outdated processes to future-ready performance. A tool that doesn’t just cut materials — it cuts through inefficiencies, costs, and complexity.

Imagine this:

- No dies. No presses. No delays.

- No guessing. No errors. No excess.

- Just clean, fast, consistent 2D and 3D laser cutting — backed by one of the industry’s most trusted laser pioneers.

Ready to See What You’re Missing?

Every manufacturing shift has its moment — the point where new technology becomes the new norm. For 3D laser cutting, that moment is now. And the machine setting that standard is the SLTL X5.

Don’t just keep up. Leap ahead.

Schedule your personalized X5 demo today and experience the future of cutting — for yourself.

📞 Call: +91 99250 36495

📧 Email: mkt@sltl.com

🔗 Visit: www.sltl.com/X5