High-power fiber lasers are replacing plasma and oxyfuel at record speed. Faster cuts, cleaner edges, and massive cost savings are pushing manufacturers to upgrade now. With SLTL leading the shift, staying with old tech means falling behind.

The metal fabrication industry is undergoing a major transformation. For decades, plasma cutting and oxyfuel cutting were the preferred methods for cutting thick metals in heavy engineering, construction, and fabrication sectors. But today, high-power fiber laser cutting is rapidly reshaping global manufacturing standards.

From speed and precision to energy savings and return on investment, fiber lasers are proving to be a superior cutting solution. Companies like SLTL Group have been at the forefront of accelerating this shift by offering advanced high-power laser cutting systems designed for modern industry needs.

This blog explores why fiber lasers are replacing traditional technologies and how SLTL is leading innovation in this field.

Why Manufacturers Are Moving Away from Plasma & Oxyfuel

1.1 Limitations of Plasma Cutting

Plasma cutting is widely used for medium- to thick-material cutting, but it has significant drawbacks:

- High heat input causes wider kerf and more distortion

- Requires extensive post-processing (grinding, cleaning)

- Consumable costs are high

- Lower accuracy for intricate designs

- Higher electricity usage

Limitations of Oxyfuel Cutting

Oxyfuel is useful for extremely thick materials, but it comes with challenges:

- Very slow cutting speed

- Only suitable for carbon steel

- Requires pre-heating

- Produces rough edges, scaling, and slag

- High gas consumption

As industries move toward precision, automation, and energy efficiency, these limitations create bottlenecks in production.

Advantages High-Power Fiber Laser Cutting

Over the last decade, fiber laser technology has advanced dramatically – especially in the 10kW to 40kW power range. This has unlocked new possibilities for cutting thicker metals with exceptional speed and quality.

Unmatched Cutting Speed

High-power fiber lasers cut significantly faster than plasma and oxyfuel.

Example Comparisons:

- A 12kW fiber laser can cut 12mm mild steel 3–5 times faster than plasma.

- A 20kW laser cuts 20–25mm mild steel at speeds oxyfuel cannot approach.

- Piercing time is reduced by up to 80%, boosting production cycles.

This enables manufacturers to complete more jobs in less time, increasing throughput without investing in more manpower.

Industry-Leading Precision

Fiber lasers produce extremely fine beams with micron-level accuracy.

Benefits include:

✔ Ultra-smooth edges

✔ Minimal heat-affected zone (HAZ)

✔ Tight tolerances for complex shapes

✔ No need for secondary finishing

This precision is essential for industries such as automotive, EV, aerospace, furniture, construction, and fabrication.

Massive Energy Savings

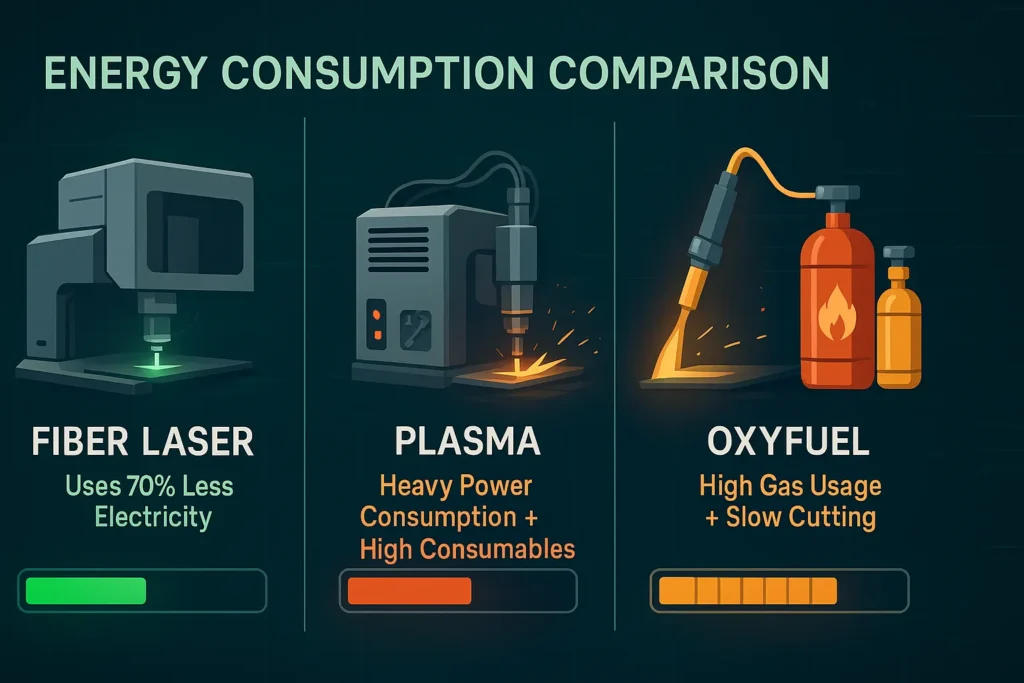

Compared to plasma and oxyfuel, fiber lasers are much more energy efficient.

Energy Consumption Comparison:

- Fiber Laser: Uses 70% less electricity

- Plasma: Heavy power consumption + frequent consumables

- Oxyfuel: High gas usage + slow cutting time

By reducing operating costs, manufacturers improve profit margins while supporting sustainability goals.

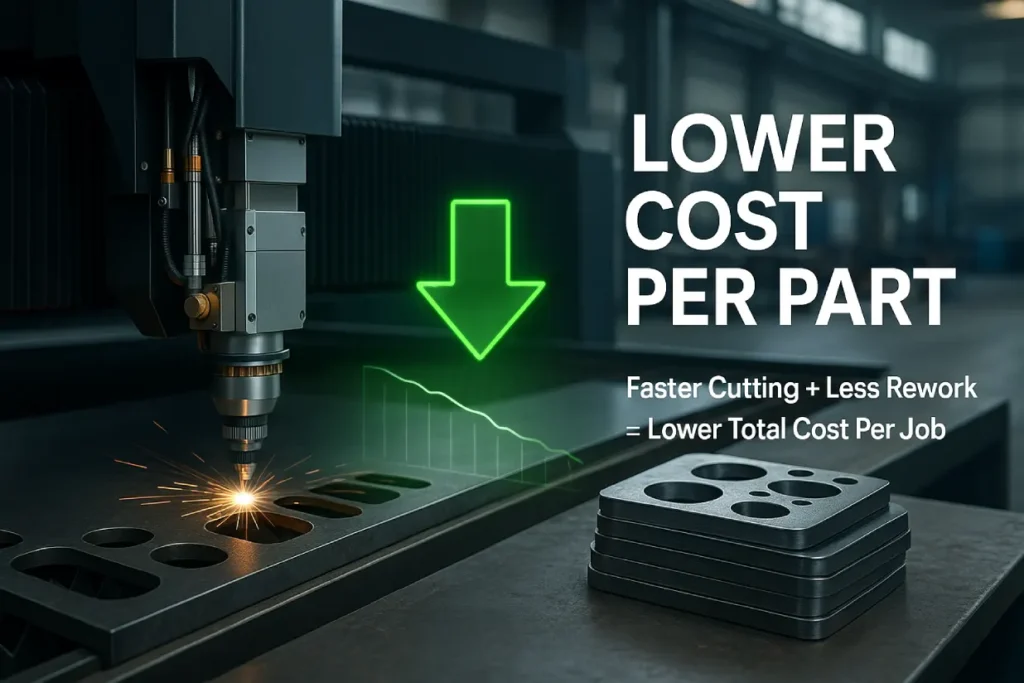

ROI: Why Fiber Laser Is a Smarter Investment

Switching to fiber laser cutting results in long-term financial benefits:

Lower cost per part: Faster cutting + less rework = lower total cost per job.

Reduced consumables: No electrodes, nozzles, tips, or heavy gas usage like plasma/oxyfuel.

Better material utilization: Thin kerf width improves nesting efficiency.

24/7 Automation-Compatible

Fiber lasers integrate easily with:

- Loaders

- Unloaders

- Sorting robots

- Smart warehouses

This unlocks lights-out manufacturing, where the machine works even without operators.

Real-World Example: How Fiber Laser Boosted Productivity

Case Study:

A heavy fabrication company cutting 12–20mm mild steel replaced two plasma machines with a 15kW fiber laser system.

Results after 6 months:

- 48% faster production

- 60% reduction in post-processing time

- 35% savings in electricity and consumables

- Achieved ROI in less than 15 months

This showcases why large and small fabricators around the world are transitioning to high-power fiber lasers.

SLTL Group: Leading the Innovation in High-Power Fiber Laser Technology

SLTL Group (Sahajanand Laser Technology Ltd.) is one of the industry leaders pushing the boundaries of high-power fiber laser technology.

How SLTL Is Transforming the Industry:

Advanced High-Power Laser Machines

SLTL offers fiber laser cutting solutions ranging from 6kW to 40kW – built for maximum speed, stability, and accuracy.

Breakthrough Features

- Dynamic beam control technology

- Intelligent piercing systems

- Energy-efficient laser sources

- High-acceleration machines for fast movement

- Automation-ready architecture

Cutting Up To 40mm and Beyond

SLTL’s powerful systems can cut thick steel plates with quality comparable to polished plasma finishing – but at 4X the speed.

Smart Manufacturing Integration

SLTL machines are IoT-enabled, offering real-time:

- Machine diagnostics

- Predictive maintenance

- Data analytics

- Performance monitoring

Global Industry Trust

From automotive OEMs to yellow-goods manufacturers and heavy fabrication units, SLTL’s high-power laser cutting systems are used in demanding industrial environments.

The Future: Fiber Laser Will Dominate Metal Cutting

The shift from plasma and oxyfuel to fiber laser is not just a trend – it’s a long-term transformation.

Manufacturers who adopt high-power fiber laser cutting today gain:

- Faster production

- Superior part quality

- Lower operating costs

- Sustainability advantages

- Competitive edge in the market

With innovation-driven leaders like SLTL Group bringing next-generation laser systems to the global industry, the future of metal cutting is clear: Fiber Laser Technology is the New Standard.