Choosing the wrong laser cutting machine manufacturer can cost you years of productivity. This guide shows how to pick the right partner, avoid hidden costs, and stay competitive before outdated decisions slow your factory down.

In today’s highly competitive manufacturing landscape, precision, speed, and efficiency are no longer optional—they are essential. One technology that has transformed industrial fabrication across automotive, aerospace, construction, electrical, and sheet metal industries is the laser cutting machine. However, while choosing the right laser cutting technology is important, selecting a reliable Laser Cutting Machine Manufacturer is even more critical for long-term success.

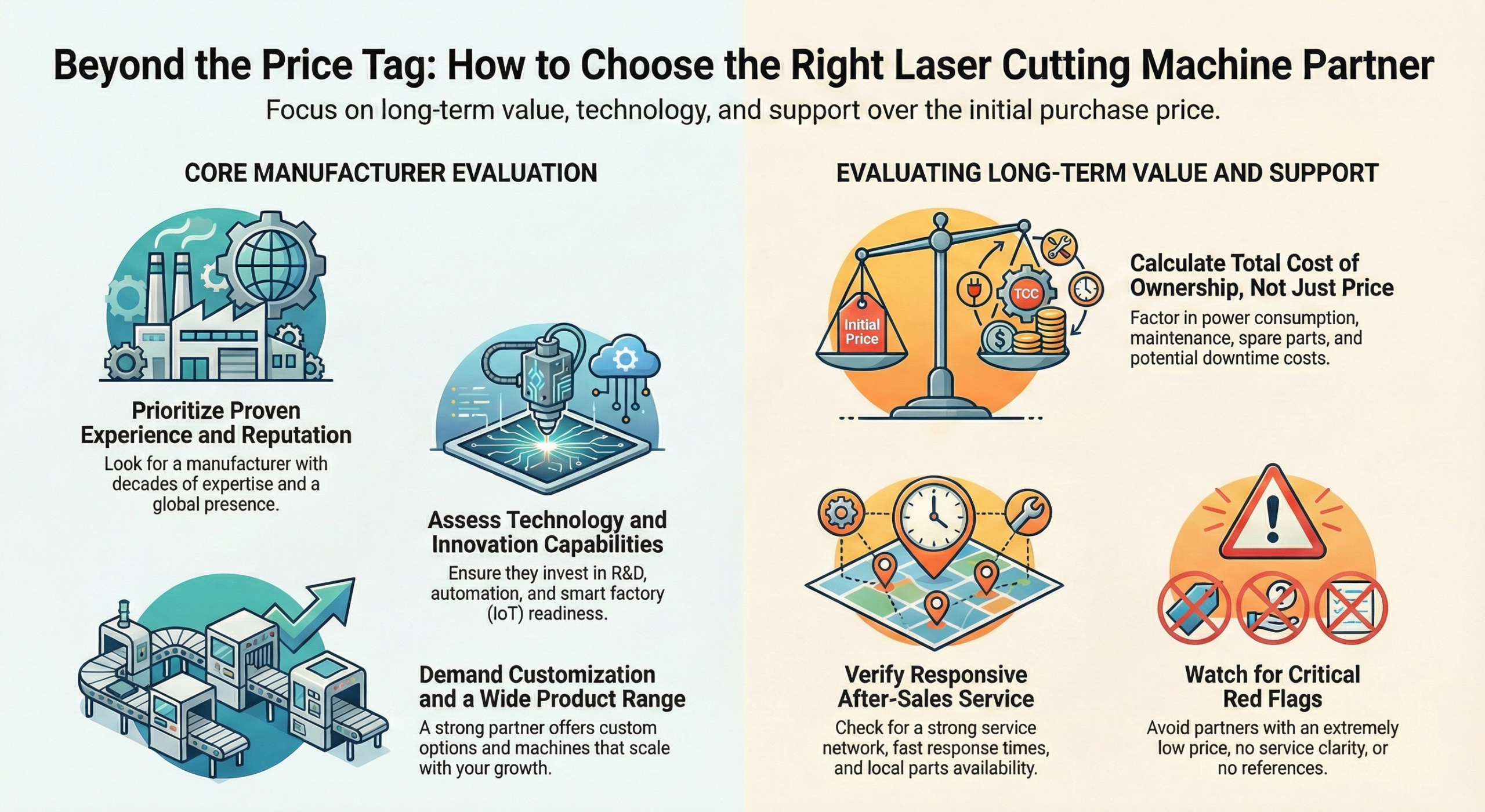

This guide will help factory owners, production managers, and decision-makers understand how to evaluate laser cutting machine manufacturers, compare laser cutting machine price factors, and choose a partner that supports productivity, quality, and growth.

Understanding the Importance of a Laser Cutting Machine in Modern Factories

A laser cutting machine uses a high-powered laser beam to cut metal sheets and other materials with exceptional accuracy and clean edges. Compared to traditional cutting methods like plasma or oxy-fuel cutting, laser cutting offers:

- High precision and repeatability

- Faster cutting speeds

- Minimal material wastage

- Clean, burr-free edges

- Lower secondary processing costs

These advantages make laser cutting machines indispensable for factories focusing on productivity and consistent quality.

However, not all machines deliver the same results. The performance of your laser cutting system depends heavily on the expertise, technology, and support provided by the Laser Cutting Machine Manufacturer.

Why Choosing the Right Laser Cutting Machine Manufacturer Matters

Purchasing a laser cutting machine is a long-term investment. The right manufacturer ensures:

- Stable machine performance for years

- Reliable after-sales service and spare parts availability

- Continuous software and technology upgrades

- Training and technical support for operators

An unreliable manufacturer may offer a lower laser cutting machine price, but hidden costs such as downtime, poor service, and inconsistent quality can significantly impact production.

Choosing a reputable Laser Cutting Machine Manufacturer is about value, not just price.

Key Factors to Consider When Selecting a Laser Cutting Machine Manufacturer

1. Manufacturing Experience and Industry Reputation

Experience matters. A manufacturer with decades of expertise understands real-world factory challenges better than a newcomer. Look for:

- Years of operation in laser technology

- Global or regional presence

- Installations across multiple industries

- Client testimonials and case studies

A trusted Laser Cutting Machine Manufacturer builds machines that perform consistently across different production environments.

2. Technology and Innovation Capabilities

Laser technology evolves rapidly. The manufacturer you choose should invest heavily in R&D and innovation. Key technological aspects to evaluate include:

- Fiber laser source quality

- CNC control systems

- Automation and material handling integration

- IoT and smart factory readiness

- Energy efficiency and power optimization

Advanced features may slightly increase the laser cutting machine price, but they dramatically improve productivity and long-term cost efficiency.

3. Laser Cutting Machine Price vs Total Cost of Ownership

One of the most common mistakes buyers make is focusing only on the upfront laser cutting machine price. Instead, evaluate the total cost of ownership, including:

- Power consumption

- Maintenance costs

- Spare parts availability

- Machine uptime and reliability

- Software upgrades and service contracts

A reliable Laser Cutting Machine Manufacturer provides transparent pricing and helps customers calculate long-term ROI rather than pushing a low initial price.

4. Range of Laser Cutting Machines Offered

A good manufacturer offers a wide product portfolio to match different factory needs, such as:

- Entry-level laser cutting machines for small workshops

- Mid-range machines for growing factories

- High-power fiber laser cutting machines for heavy industries

- Tube laser cutting machines

- 3D laser cutting systems

This flexibility indicates technical depth and ensures scalability as your factory grows.

5. Customization and Automation Options

Every factory has unique production requirements. A reliable Laser Cutting Machine Manufacturer should offer:

- Custom bed sizes

- Power options based on material thickness

- Automated loading and unloading systems

- Integration with existing production lines

Automation may increase the laser cutting machine price initially, but it reduces labor costs, errors, and downtime in the long run.

Evaluating After-Sales Service and Support

1. Installation, Training, and Commissioning

A laser cutting machine is only as good as its setup. Ensure the manufacturer provides:

- On-site installation and commissioning

- Operator and maintenance training

- Safety guidelines and best practices

Professional onboarding ensures faster production readiness and fewer operational issues.

2. Availability of Spare Parts and Consumables

Downtime can be costly. A reliable Laser Cutting Machine Manufacturer maintains:

- Local or regional spare parts warehouses

- Fast delivery timelines

- Standardized consumables like nozzles and lenses

Consistent spare part availability protects your factory from production delays.

3. Service Network and Response Time

Before finalizing your purchase, ask:

- How many service engineers are available in your region?

- What is the average response time for breakdowns?

- Is remote diagnostics available?

A slightly higher laser cutting machine price is justified if the manufacturer offers faster service and minimal downtime.

Comparing Domestic vs Global Laser Cutting Machine Manufacturers

Both domestic and global manufacturers have their advantages.

Domestic Manufacturers

- Competitive laser cutting machine price

- Faster local service support

- Better understanding of regional factory needs

Global Manufacturers

- Advanced automation and software

- Proven international installations

- Strong R&D capabilities

The best choice depends on your production scale, export requirements, and long-term growth plans.

Certifications and Quality Standards to Look For

A reliable Laser Cutting Machine Manufacturer complies with international standards such as:

- ISO certifications

- CE marking

- Electrical and safety compliance

- Quality control systems

These certifications ensure machine reliability, safety, and acceptance in global markets.

Industry-Specific Experience Matters

Different industries have different cutting requirements. Choose a manufacturer with experience in your sector, such as:

- Automotive and EV components

- Sheet metal fabrication

- Electrical panels

- Aerospace parts

- Construction and heavy engineering

Industry expertise ensures optimized machine configuration and better application support.

Understanding Laser Cutting Machine Price Segmentation

Laser cutting machine price varies based on multiple factors:

- Laser power (kW rating)

- Bed size and structure

- Automation level

- Software and control systems

- Brand reputation and service coverage

Entry-level machines may start at a lower price, while fully automated industrial systems command a premium. A trusted Laser Cutting Machine Manufacturer explains these differences clearly, helping you choose the right machine for your budget and production needs. To know more, contact us today at +91 9925036495.

Long-Term Partnership Over One-Time Purchase

A laser cutting machine is not a short-term asset. The right manufacturer acts as a long-term technology partner by offering:

- Regular software updates

- Machine upgrades and retrofitting

- Production optimization support

- New technology adoption guidance

This partnership approach ensures your factory stays competitive for years.

Red Flags to Avoid When Choosing a Manufacturer

Be cautious if you notice:

- Extremely low laser cutting machine price with no service clarity

- Lack of physical manufacturing facility

- No references or customer installations

- Poor documentation or warranty terms

A reliable Laser Cutting Machine Manufacturer prioritizes transparency and trust.

Final Thoughts: Making the Right Decision for Your Factory

Choosing a reliable Laser Cutting Machine Manufacturer is a strategic decision that directly impacts your factory’s productivity, quality, and profitability. While laser cutting machine price is an important factor, it should never outweigh performance, service reliability, and long-term value.

Investing in the right laser cutting machine and partnering with a trusted manufacturer ensures:

- Higher production efficiency

- Consistent quality output

- Reduced downtime

- Better return on investment

By carefully evaluating technology, service support, industry experience, and total cost of ownership, you can confidently select a laser cutting solution that supports your factory’s present needs and future growth.