Know how fiber laser cutting shapes metal with speed, accuracy, and less waste. From how it works to why industries trust it; discover the process, benefits, and its growing role in modern manufacturing. Don’t miss what’s powering smart factories today.

Fiber laser cutting is an advanced and highly efficient technology that utilizes a fiber-optic laser source to cut through various materials with unmatched precision. It has transformed industries such as automotive, aerospace, electronics, and metal fabrication, offering high-speed cutting, minimal material wastage, and superior edge quality. Unlike traditional cutting methods, fiber laser cutting is non-contact, ensuring minimal mechanical stress on the material. This technology is widely used due to its ability to process a range of materials, including stainless steel, aluminum, brass, titanium, and more using advanced fiber laser cutting machines designed for precision and efficiency. In this blog, we will explore the working principles, process, and benefits of fiber laser cutting.

What is Fiber Laser Cutting?

Fiber laser cutting is a thermal cutting process that uses a highly concentrated laser beam generated by a fiber-optic laser source. This beam is directed onto the material, where its intense energy causes localized melting, vaporization, or burning, resulting in a precise cut. The entire process is controlled using computer numerical control (CNC) systems, ensuring high accuracy and repeatability. Fiber laser cutting is widely used for cutting metals due to its ability to create clean, burr-free edges with minimal material waste. To better understand the basics behind this method, you can also check out what is laser technology.

How Fiber Laser Cutting Works?

The fiber laser cutting process involves several key stages that contribute to its efficiency and precision:

1. Generating the Laser Beam

The process begins with a fiber laser source, which uses optical fibers doped with rare-earth elements like ytterbium to generate a powerful laser beam. The fiber laser source produces a beam with a shorter wavelength (usually 1.06 microns) compared to CO2 lasers, allowing for better absorption in metal materials.

Source: ScienceDirect

2. Beam Delivery and Focusing

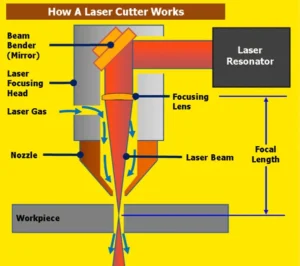

The laser beam is transmitted through a flexible fiber-optic cable, eliminating the need for complex mirror systems. It is then focused using a collimation and focusing lens, creating a small, high-intensity spot capable of cutting through thick materials with exceptional precision. The focused beam delivers high power density, ensuring clean and fast cuts.

3. Material Interaction

When the laser beam makes contact with the workpiece, it generates intense heat that rapidly melts or vaporizes the material. The high energy concentration ensures minimal heat-affected zones, preventing distortion or warping in thin materials. The precision of fiber laser cutting makes it ideal for intricate patterns and complex geometries.

4. Assist Gas Application

During fiber laser cutting, an assist gas, such as nitrogen, oxygen, or compressed air-is used to enhance the cutting process and improve edge quality:

- Oxygen: Used for cutting mild steel, creating an exothermic reaction that helps speed up the process.

- Nitrogen: Used for cutting stainless steel, aluminum, brass and similar metals, preventing oxidation and ensuring a clean, burr-free cut.

- Compressed Air: A cost-effective option for cutting thin to medium sheets while maintaining decent edge quality with high productivity.

To understand the role of assist gases in more detail, including how to choose the right one for your application, explore our guide on how assist gases transform fiber laser cutting with practical insights and best practices.

5. CNC Control for Precision

Fiber laser cutting machines are equipped with CNC control systems that automate the cutting process. The CNC software allows operators to program intricate designs, control cutting speed, and optimize power settings. This ensures high precision and repeatability across multiple production runs. For specialized applications like tube cutting, you can also explore our SLTL advance software for tube cutting that brings even more control and efficiency.

What are the Advantages of Fiber Laser Cutting?

Fiber laser cutting offers numerous advantages that make it the preferred choice in modern manufacturing:

- Higher Efficiency: Fiber lasers convert electrical energy into laser energy with higher efficiency (over 40%), reducing operational costs.

- Superior Cutting Speed: Faster processing speeds compared to CO2 and traditional cutting methods, especially for thin to medium-thickness metals.

- Minimal Maintenance: No mirrors or moving parts in the laser source, resulting in lower maintenance requirements and longer lifespan.

- Exceptional Precision: Delivers high-accuracy cuts with minimal kerf width and heat-affected zones.

- Energy-Efficient & Eco-Friendly: Consumes less power and produces fewer emissions, contributing to a greener manufacturing process.

- Versatility: Capable of cutting a variety of metals, including stainless steel, mild steel, brass, copper, aluminum and many more.

To see how these benefits are shaping real-world applications, check out how fiber laser cutting machines are revolutionizing the sheet metal industry with their speed, accuracy, and automation-ready features.

What are the Applications of Fiber Laser Cutting?

Due to its precision and efficiency, fiber laser cutting is widely used in various industries:

- Automotive: Used for cutting intricate body panels, chassis components, and exhaust systems.

- Aerospace: Enables the cutting of lightweight, high-strength materials for aircraft structures.

- Electronics: Applied in the manufacturing of precision electronic enclosures and heat sinks.

- Medical Devices: Essential for producing intricate surgical tools and implantable medical devices.

- Metal Fabrication: Used for creating custom sheet metal parts, decorative panels, and industrial components.

Future of Fiber Laser Cutting

With ongoing advancements in laser technology, fiber laser cutting continues to evolve. The integration of artificial intelligence (AI), automation, and IoT-enabled smart manufacturing is enhancing productivity and precision. Developments in ultra-fast fiber lasers and beam shaping technologies are further improving cut quality and processing speed. As industries seek more efficient and sustainable solutions, fiber laser cutting is set to remain at the forefront of modern manufacturing.

Conclusion

Fiber laser cutting has revolutionized the manufacturing industry by providing unparalleled precision, efficiency, and cost-effectiveness. Its ability to process a wide range of metals at high speed and minimal waste makes it an indispensable tool in various sectors. As technology continues to advance, fiber laser cutting will play a crucial role in shaping the future of industrial production.

If you want to learn more or need guidance about how fiber laser cutting machine can help you grow your business, SLTL is always here to help. You can reach us at +91 9925036495 or mail at mkt@SLTL.com today.