Mysore’s manufacturing identity has quietly but steadily evolved over the past decade. Once known primarily for heritage industries and small-scale production, the city today supports a growing base of precision fabrication units, engineering MSMEs, automotive ancillary suppliers, electrical panel manufacturers, food-processing machinery builders, and export-oriented workshops. As this transition accelerates, Mysore manufacturers are facing a common inflection point-traditional fabrication methods are no longer sufficient to meet modern quality, speed, and cost expectations.

This is where the laser cutting machine has become a defining technology for Mysore’s industrial future. Across the city, workshops and factories are moving toward metal laser cutting machines, CNC laser cutting machines, sheet metal laser cutting machines, and advanced laser machines for metal cutting to gain tighter tolerances, predictable output, and scalable production. SLTL Group, India’s pioneering laser manufacturer, is enabling this shift by delivering machines designed for Indian manufacturing realities-robust, efficient, and future-ready.

With IMTEX 2026 approaching, Mysore’s manufacturers are actively evaluating how laser technology can help them compete not just locally, but nationally and globally.

Mysore’s Industrial Landscape: From Conventional Fabrication to Precision Manufacturing

Mysore’s industrial ecosystem is largely MSME-driven, with a strong presence of:

- Sheet metal fabrication workshops

- Automotive and tractor component suppliers

- Electrical panel and enclosure manufacturers

- Precision engineering and machining units

- Food-processing and packaging machinery manufacturers

- Stainless steel furniture and architectural metal fabricators

Unlike metro-driven heavy manufacturing clusters, Mysore’s strength lies in flexibility, customization, and multi-variant production. However, this also creates pressure: customers demand faster deliveries, better finish quality, tighter tolerances, and consistent repeatability-expectations that are difficult to meet using plasma cutting, shearing, punching, or manual methods alone.

As a result, manufacturers across Mysore are transitioning toward CNC laser cutting machines and 2D laser cutting machines that can handle frequent design changes without tooling delays while maintaining accuracy across batches.

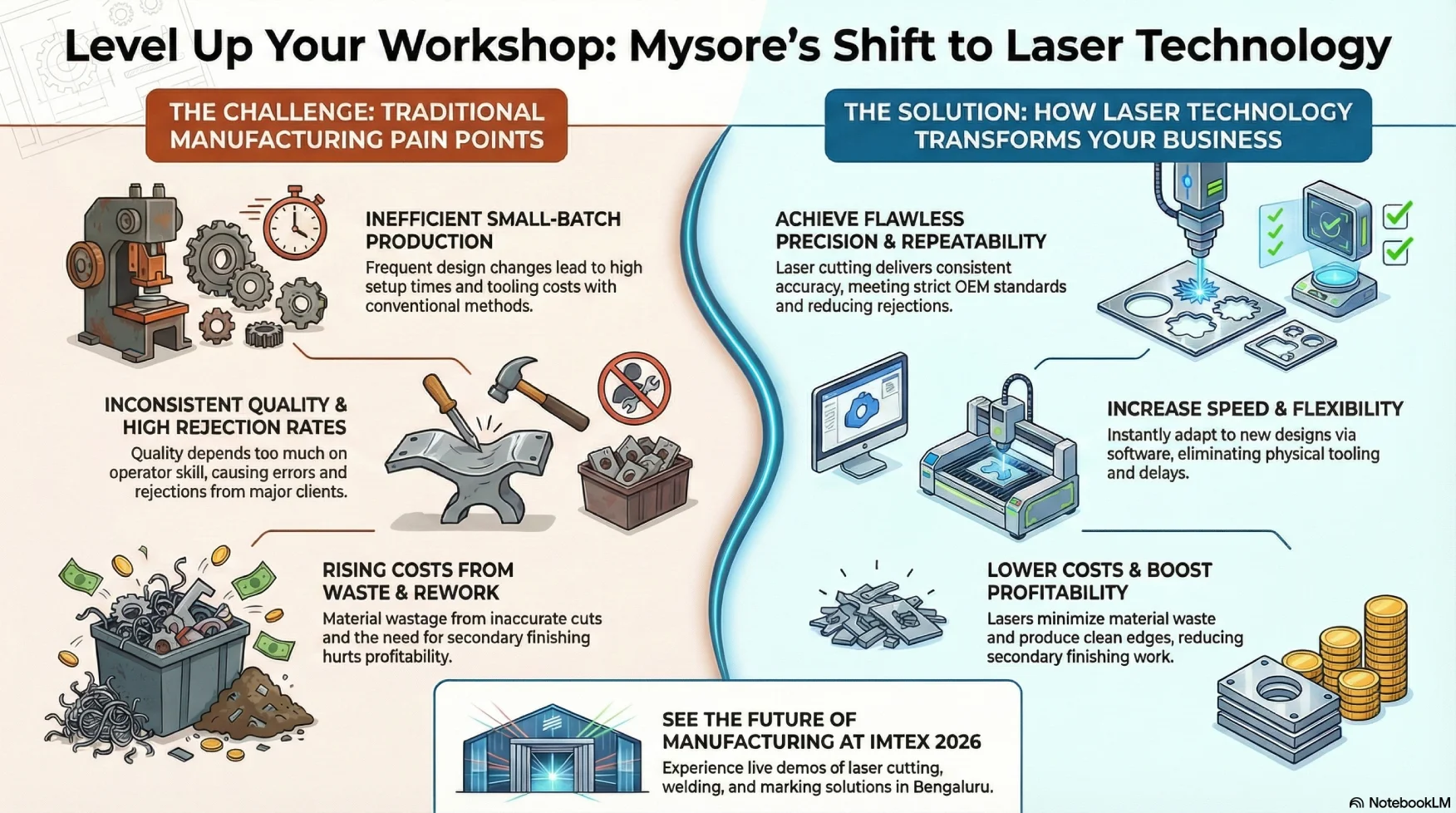

Manufacturing Pain Points Unique to Mysore-Based Industries

While Mysore industries are ambitious, they face region-specific operational challenges that directly influence technology adoption.

- High Mix, Low Volume Production: Many Mysore units handle small batch sizes with frequent design changes. Conventional processes struggle with setup time and tooling costs, whereas a laser cutting machine for metal adapts instantly through software.

- Skilled Labor Dependency: Fabrication quality often depends on operator skill, creating inconsistency. Laser machines reduce this dependency by standardizing cut quality regardless of operator experience.

- Space Constraints: Urban and semi-urban industrial layouts limit expansion. Compact sheet metal laser cutting machines allow higher output within existing floor space.

- Quality Rejections from OEMs: Automotive and engineering customers demand strict tolerances. Laser cutting ensures repeatable accuracy, reducing rework and rejection rates.

- Rising Input Costs: Material wastage and secondary finishing increase costs. Laser nesting and clean edges directly improve material utilization and profitability.

Industry-Wise Demand for Laser Cutting Machines in Mysore

Sheet Metal & Job Shop Fabrication : This is the largest demand segment in Mysore. Fabricators producing brackets, cabinets, frames, trays, and panels rely on sheet metal laser cutting machines to achieve clean edges, uniform holes, and faster turnaround times.

Automotive & Tractor Ancillaries : Component suppliers manufacturing mounts, guards, frames, and structural parts increasingly use metal laser cutting machines and 2D laser cutting machines to meet OEM dimensional standards.

Electrical Panels & Enclosures : Electrical manufacturers require consistent cut-outs, slots, and patterns. CNC laser cutting machines ensure accuracy while enabling easy design updates.

Furniture & Architectural Metal : Laser cutting allows intricate patterns, decorative panels, and premium finishes-driving demand from stainless steel furniture and interior design fabricators.

Tube & Structural Fabrication : Frames, stands, supports, and welded assemblies benefit from tube laser cutting machines, which improve joint fit-up and reduce welding errors.

Local Exhibitions & Technology Exposure for Mysore Manufacturers

Mysore manufacturers actively track technology trends through exhibitions and trade platforms. While regional expos introduce incremental upgrades, national exhibitions remain the primary decision-making arenas.

Among them, IMTEX Forming 2026 stands out as the most influential event for evaluating laser cutting, marking, and welding technologies. For Mysore industries, IMTEX serves as a space to:

- Compare laser cutting machine configurations

- Understand automation possibilities

- Evaluate real cutting quality

- Interact with application engineers

- Plan long-term manufacturing upgrades

SLTL Group’s Laser Machine Portfolio for Mysore Industries

SLTL Group offers a broad range of laser systems designed to support Mysore’s diverse manufacturing requirements.

Laser Cutting Machines

- 2D laser cutting machines for precision sheet metal processing

- Metal laser cutting machines for MS, SS, aluminium, brass, and copper

- CNC laser cutting machines with automation readiness

- Tube laser cutting machines for round, square, and profile sections

These machines are engineered for stability, consistent performance, and long production cycles-ideal for Mysore’s mixed-production environment.

Beyond Cutting: Laser Marking & Laser Welding Solutions

Laser Marking Machines

Mysore manufacturers increasingly require permanent identification for traceability, branding, and compliance. SLTL’s laser marking systems deliver:

- Non-contact, permanent marking

- Serial numbers, logos, QR codes

- High-speed marking without consumables

- Minimal maintenance

These systems are widely used in electrical, automotive, and engineering components.

Laser Welding Machines

Laser welding is gaining traction in Mysore for stainless steel fabrication, thin-sheet assemblies, and precision joints. SLTL’s laser welding solutions offer:

- Narrow, clean weld seams

- Minimal heat distortion

- Strong, consistent joints

- Reduced post-weld finishing

This is particularly valuable for furniture, enclosures, and precision assemblies.

Local Pricing Insights: Laser Cutting Machine Cost in Mysore

The laser cutting machine price in Mysore typically varies based on:

- Laser power capacity

- Bed size and working area

- Automation level

- Material thickness range

- Application complexity

SLTL provides Mysore manufacturers with:

- India-manufactured machines

- Transparent pricing structures

- Lower operating and service costs

- Faster ROI compared to imported alternatives

This makes laser adoption viable even for growing MSMEs.

New SLTL Innovations Relevant to Mysore (IMTEX 2026 Focus)

Infinity F1 : A high-speed fiber laser cutting platform designed for productivity-focused fabrication units handling continuous batches.

Vector : Built for accuracy-driven manufacturers, Vector offers exceptional beam stability and cutting consistency-ideal for engineering and OEM suppliers.

Neo – Laser Marking Series

Compact, efficient marking systems designed for factory-floor integration, traceability, and branding.

These innovations are particularly aligned with Mysore’s need for precision without operational complexity.

Why Mysore Manufacturers Choose SLTL

- Indian manufacturing expertise with global technology

- Machines engineered for Indian shopfloor conditions

- Strong application engineering support

- Reliable performance across materials

- Lower lifecycle costs

- Scalable solutions for growing businesses

SLTL’s understanding of MSME realities makes it a preferred partner for Mysore industries transitioning to advanced manufacturing.

Customer Experience Snapshot

Many Mysore-based fabricators report:

- Improved cut accuracy

- Faster delivery timelines

- Reduced material wastage

- Lower dependency on skilled labor

- Better acceptance from OEM customers

These outcomes reinforce confidence in laser technology as a long-term investment.

Local Technical Support & Service Availability

SLTL supports Mysore manufacturers with:

- Regional service engineers

- Quick-response technical support

- Operator training programs

- Spare part availability

- Preventive maintenance services

This ensures uninterrupted production and peace of mind for local businesses.

Experience the Future of Manufacturing at IMTEX 2026

Mysore manufacturers planning their next growth phase should experience SLTL’s laser solutions live at IMTEX 2026. From cutting and marking to welding and automation, IMTEX offers the clarity needed to make confident investment decisions.

IMTEX 2026

Date: 21 – 25 January, 2026

Hall No: 04

Booth No: B – 130

Venue: Bangalore International Exhibition Centre, Bengaluru, Karnataka

👉 Register for IMTEX 2026 and explore SLTL’s laser technologies.

Mysore’s manufacturing future is no longer defined by scale alone-it is defined by precision, adaptability, and efficiency. As industries modernize, laser cutting machines, laser marking systems, and laser welding solutions are becoming essential tools rather than optional upgrades. With its deep expertise and India-first approach, SLTL Group stands ready to support Mysore’s next phase of industrial growth-starting at IMTEX 2026.

Local FAQs – Mysore Laser Buyers

Q1. Is a laser cutting machine suitable for small workshops in Mysore?

Yes. Compact laser systems are ideal for MSMEs handling varied jobs with limited space.

Q2. Can laser machines handle frequent design changes?

Absolutely. Design changes are software-based, requiring no physical tooling.

Q3. What materials can SLTL laser machines cut?

Mild steel, stainless steel, aluminium, brass, copper, and more.

Q4. Is service support available near Mysore?

Yes. SLTL provides regional technical and service support across Karnataka.

Q5. Can one machine support multiple applications?

Yes. A single CNC laser cutting machine can handle diverse components and industries.