Introduction: Precision Manufacturing for Heavy Equipment

The earth-moving equipment industry plays a critical role in infrastructure development, mining, construction, and agriculture. Machines like excavators, bulldozers, loaders, and graders rely on extremely strong structural components manufactured from heavy steel plates. These components must withstand high stress, vibration, and harsh operating environments.

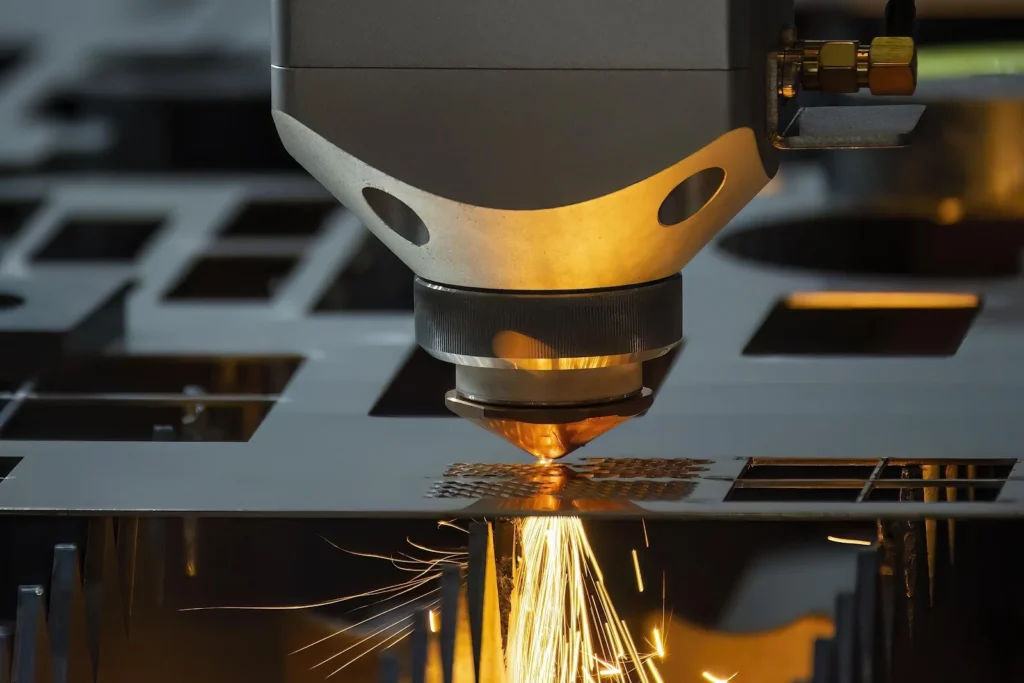

Traditional cutting methods such as oxy-fuel cutting, plasma cutting, and mechanical machining have long been used in heavy equipment manufacturing. However, modern production demands higher precision, faster throughput, improved edge quality, and reduced material waste. This is where the laser cutting machine for heavy equipment fabrication becomes a transformative technology.

Today, manufacturers are increasingly adopting fiber laser cutting machines for heavy plates to achieve consistent quality and production efficiency in heavy fabrication processes.

The Role of Heavy Plate Fabrication in Earth-Moving Equipment

Heavy equipment manufacturing involves the fabrication of thick metal components that form the backbone of construction machinery. These components include:

- Excavator arms and booms

- Loader frames and chassis plates

- Bucket components and cutting edges

- Reinforcement plates and brackets

- Structural machine frames

- Mining equipment panels

These parts are typically made from high-strength steel plates ranging from 6 mm to over 40 mm thickness, requiring powerful and accurate cutting technologies.

A high power laser cutting machine enables manufacturers to cut these heavy plates with remarkable accuracy while maintaining structural integrity.

Challenges in Cutting Thick Metal Plates

Fabricating heavy equipment components involves several challenges:

1. Maintaining Precision in Thick Materials: Thick steel plates are difficult to cut with conventional methods without producing uneven edges or excessive heat-affected zones.

2. Material Waste: Manual cutting or outdated technologies often result in poor nesting efficiency and increased scrap.

3. Secondary Processing: Traditional cutting methods often require grinding, finishing, or machining after cutting.

4. Production Speed: Heavy equipment manufacturing requires consistent production timelines, which older technologies struggle to maintain.

This is why laser cutting thick metal has become the preferred approach in modern fabrication facilities.

Fiber Laser Cutting Machine for Heavy Plates

Precision and Power Combined

A fiber laser cutting machine for heavy plates uses a high-power laser beam to melt and remove material with exceptional precision. These machines are designed specifically to handle thick metal sheets used in heavy equipment fabrication.

Modern systems can cut:

- Mild steel up to 40 mm or more

- Stainless steel thick plates

- High-strength structural steel

- Alloy steel plates

Unlike traditional cutting technologies, fiber lasers deliver clean edges, minimal distortion, and consistent cut quality.

Benefits of Laser Cutting in Heavy Equipment Fabrication

1. High Precision for Structural Components

Heavy equipment parts must align perfectly during assembly. Laser cutting machines provide micron-level precision, ensuring accurate dimensions for:

- Excavator arms

- Chassis plates

- Bucket side panels

- Reinforcement components

This reduces assembly errors and improves machine durability.

2. Superior Edge Quality

A high power laser cutting machine produces smooth and clean edges even when cutting thick metal plates. This significantly reduces or eliminates secondary finishing processes.

Benefits include:

- Reduced grinding

- Lower labor costs

- Faster production cycles

3. Faster Production Speed

Fiber laser technology enables faster cutting compared to traditional methods. Automated loading systems, CNC control, and optimized cutting parameters allow manufacturers to increase throughput.

For heavy equipment manufacturers, this means:

- Faster project completion

- Improved production efficiency

- Higher profitability

4. Reduced Heat-Affected Zone

When cutting thick plates, controlling heat is essential to maintain material strength. Laser cutting generates a smaller heat-affected zone, preserving the mechanical properties of heavy steel components.

This is particularly important for load-bearing parts such as:

- Excavator booms

- Loader frames

- Structural brackets

5. Material Optimization and Nesting

Modern laser cutting software optimizes sheet utilization, reducing scrap and improving material efficiency.

In heavy plate fabrication, where steel costs are significant, this leads to:

- Lower raw material costs

- Better production planning

- Reduced waste

Applications in Earth-Moving Equipment Manufacturing

Excavator Arm Cutting: Excavator arms require precision-cut heavy plates to ensure strength and alignment. Laser cutting machines produce consistent profiles that simplify welding and assembly.

Chassis Plate Cutting: The chassis forms the foundation of earth-moving machinery. A fiber laser cutting machine for heavy plates ensures accurate cutting of large structural plates.

Bucket Component Cutting: Buckets experience extreme wear and impact. Laser-cut bucket plates provide consistent geometry and improved durability.

Precision Heavy Plate Cutting: Laser technology enables complex contour cutting in thick metal plates, allowing manufacturers to create advanced machine designs.

High Power Laser Cutting Machine in Modern Fabrication Plants

Automation and Productivity

A high power laser cutting machine is not just a cutting tool — it is part of a smart manufacturing ecosystem.

Modern fabrication plants integrate:

- CNC automation

- Material handling systems

- IoT monitoring

- Production tracking software

This allows heavy equipment manufacturers to maintain consistent quality and reduce downtime.

Why Laser Cutting is Replacing Traditional Methods

| Feature | Laser Cutting | Plasma Cutting | Oxy-Fuel Cutting |

| Precision | Very High | Medium | Low |

| Edge Quality | Excellent | Moderate | Rough |

| Post-Processing | Minimal | Moderate | High |

| Speed | High | Medium | Slow |

| Automation | Advanced | Limited | Minimal |

The shift toward laser cutting thick metal is driven by the need for precision engineering and production efficiency in the earth-moving industry.

Future of Heavy Equipment Manufacturing with Laser Technology

The earth-moving equipment industry is moving toward automation, digital manufacturing, and high-precision fabrication. Laser cutting technology will play a central role in this transformation.

Key future trends include:

- AI-assisted cutting optimization

- Smart factories with connected machines

- Automated heavy plate fabrication lines

- Energy-efficient high-power laser systems

As construction and mining projects grow worldwide, demand for reliable and efficient manufacturing technologies will continue to rise.

Conclusion

Heavy equipment manufacturing requires strength, precision, and reliability — all of which depend on high-quality fabrication processes. A laser cutting machine for heavy equipment fabrication provides the accuracy and efficiency needed to produce durable components for the earth-moving industry.

By using a fiber laser cutting machine for heavy plates, manufacturers can achieve:

- Precision cutting of structural components

- Faster production cycles

- Reduced material waste

- Superior edge quality

- Improved product reliability

The adoption of high power laser cutting machines is transforming heavy plate fabrication, making production smarter, faster, and more cost-effective.

As the earth-moving equipment industry continues to evolve, laser cutting thick metal will remain a cornerstone of modern heavy equipment manufacturing.