Still using outdated cutting methods? Discover why fiber laser cutting is outpacing plasma in speed, precision & cost-efficiency. From shipbuilding to aerospace — choose smarter, cut sharper. Don’t fall behind, explore the future of cutting today!

When it comes to precision metal cutting, two advanced technologies lead the industry – plasma cutting and fiber laser cutting. Each method has its strengths, making them ideal for different applications based on factors like material thickness, speed, accuracy, and cost. Whether you’re in heavy fabrication, automotive, or sheet metal processing, selecting the right cutting solution can significantly impact productivity and overall operational efficiency.

This comprehensive guide breaks down the key differences between plasma and fiber laser cutting, helping you understand their advantages and limitations. From cutting speed and precision to operating costs and material compatibility, we’ll explore how each technology performs in real-world applications. By the end, you’ll have a clear perspective on which cutting method aligns best with your manufacturing needs.

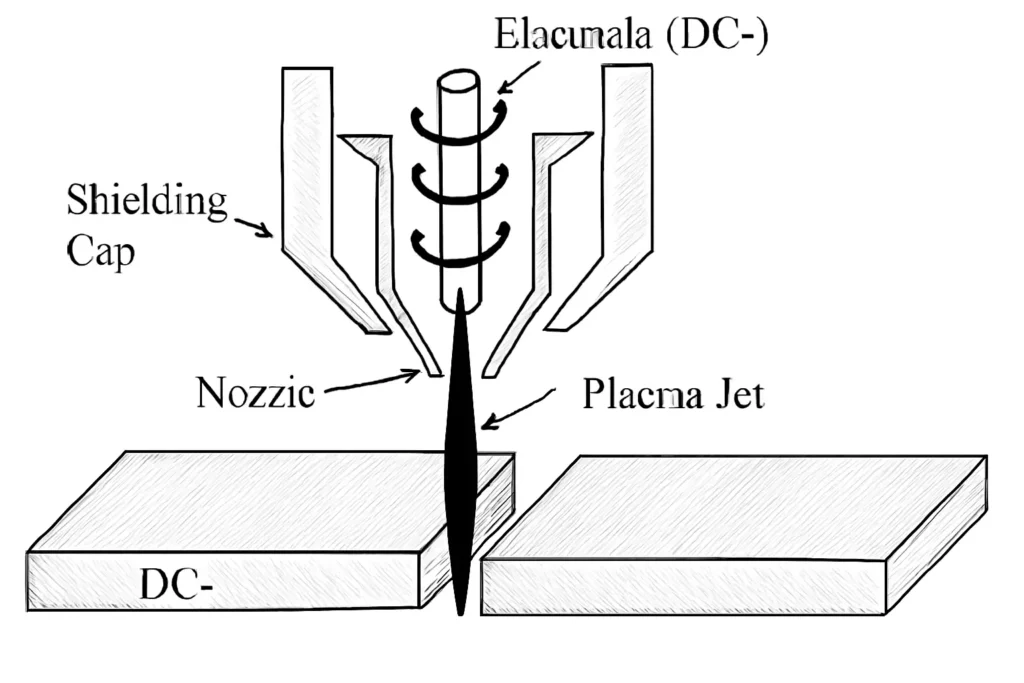

How Does Plasma Cutting Work?

Plasma cutting is a method used to cut through electrically conductive metals using hot plasma. It’s a fast and cost-effective process, mainly used for cutting thick sheets of steel, aluminum, and other metals.

Here’s how it works:

- Creates Plasma: Plasma cutting starts by sending an electric arc through a gas like oxygen, nitrogen, or argon. This process turns the gas into plasma – a super-hot, ionized gas.

- Extremely High Temperature: The plasma reaches very high temperatures, often above 20,000°C. This heat is enough to melt the metal surface instantly.

- High-Speed Jet: The plasma is forced out through a small nozzle at high speed, which melts and blows away the metal, creating the cut.

- Great for Thick Metals: It’s especially good for cutting thick metal plates and is widely used in shipbuilding, construction, and heavy equipment industries.

- Speed Over Precision: While it’s fast and powerful, plasma cutting is not the best option for fine, detailed cuts. It produces a wide cut (kerf) and a heat-affected zone (HAZ), which might require some finishing work afterward.

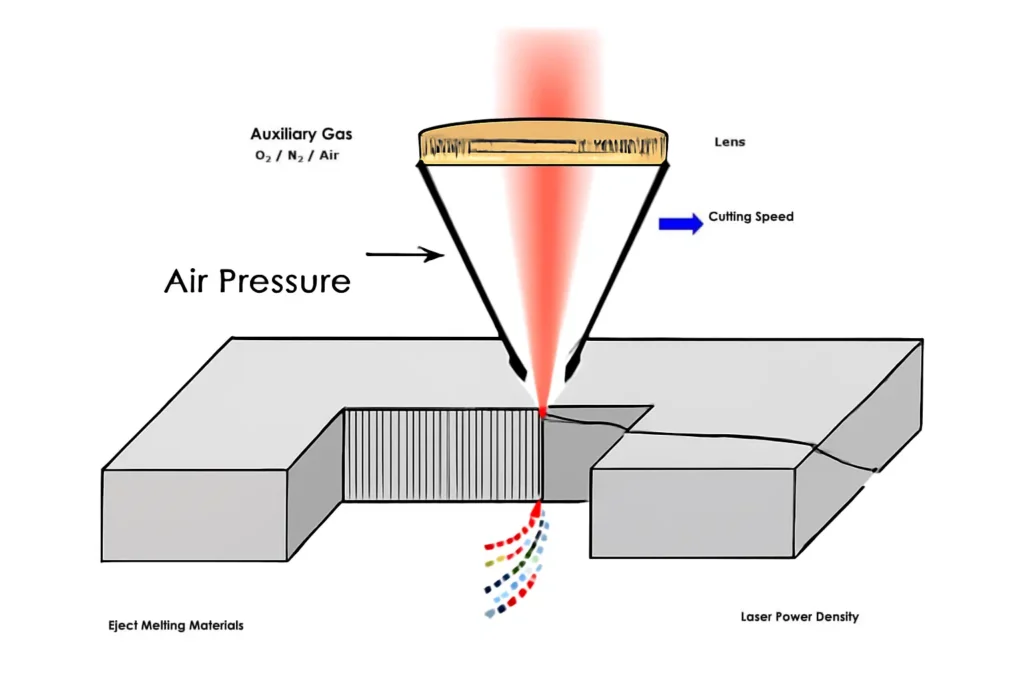

How Does Fiber Laser Cutting Work?

Fiber laser cutting is a high-precision method used for cutting metal using a focused laser beam. It’s a clean and efficient process that is perfect for thin to medium-thick materials where detail and accuracy are important.

Here’s how it works:

- Laser Through Fiber Optics: A powerful laser beam is generated using fiber optic cables. This beam is highly focused and can cut through metals very precisely.

- High Heat, No Contact: The laser melts, vaporizes, or burns the metal without any physical contact. This means less wear and tear on the machine.

- CNC Controlled: The laser is controlled by CNC (Computer Numerical Control), which allows for detailed and complex cutting patterns.

- Minimal Waste: The narrow beam means less material is wasted, and the edges are usually clean, requiring little to no finishing.

- Great for Precision Work: It’s commonly used in industries like aerospace, medical, electronics, and jewelry making, anywhere that needs fine and accurate cuts.

To know in detail, read our blog on how fiber laser cutting works.

Comparison Table: Fiber Laser Cutting vs Plasma Cutting Performance

| Feature | Fiber Laser Cutting | Plasma Cutting |

|---|---|---|

| Speed | – Significantly faster, especially on thin to medium sheets. – High-power models can also cut thick materials efficiently. |

– Slower on thin/medium sheets. – Performs well on very thick materials with steady cutting speed. |

| Accuracy | – Extremely high positioning accuracy. – Ideal for fine, detailed work in electronics, aerospace, and medical sectors. |

– Lower precision with broader tolerances. – Suitable for applications where exact dimensions are less critical. |

| Kerf Width & HAZ | – Narrow kerf (cut width). – Minimal heat-affected zone (HAZ), resulting in less material distortion. |

– Wider kerf and larger HAZ. – Can cause more distortion, especially on thinner materials. |

| Edge Quality | – Smooth, clean, burr-free edges. – Requires little to no post-processing. |

– May leave dross or rough edges that need grinding or finishing. |

| Material Handling | – Works well with stainless steel, mild steel, aluminum, copper, brass, and more. | – Ideal for thick, conductive metals in structural steel or shipbuilding applications. |

| Application Fit | – Best for high-precision industries like electronics, medical, signage, and aerospace. | – Suited for rugged, heavy-duty industries like construction, fabrication, and shipbuilding. |

| Maintenance & Cost | – Lower maintenance. – Higher initial investment. |

– More frequent part replacement. – Lower initial cost but higher maintenance. |

| Best For | – Thin to medium thickness metals. – Jobs needing precision and clean finishes. |

– Thick material cutting. – Applications where surface finish is secondary. |

Cost Analysis: Plasma vs. Fiber Laser Cutting

Initial Investment and Operating Costs Comparison between plasma and fiber laser

Plasma Cutting

Plasma cutting machines are relatively affordable, with entry-level models starting around a few thousand and high-end industrial machines reaching up to lakhs. This makes plasma cutting an attractive option for businesses that need a cost-effective solution for cutting thick metals, such as in fabrication, shipbuilding, and heavy machinery industries.

However, while the initial investment is lower, operating costs are higher due to consumables and maintenance. Key cost factors include:

- Electrodes and nozzles: These wear out over time and need frequent replacement, especially at higher power levels.

- Shielding gases: Gases like oxygen, nitrogen, or argon-hydrogen mixtures are needed for plasma cutting, adding to recurring expenses.

- Higher electricity consumption: Plasma cutters require more power than fiber lasers, increasing energy costs over time.

Additionally, plasma cutting generates a wider heat-affected zone (HAZ), often requiring secondary finishing processes like grinding or machining, leading to increased labor and material costs.

Fiber Laser Cutting

Fiber laser cutting machines have a higher initial investment, typically ranging to ₹50 lakh+, depending on laser power, cutting bed size, and automation features. Despite the higher cost, fiber lasers offer significant long-term savings due to lower operating expenses and increased efficiency.

Key cost benefits of fiber laser cutting:

- Minimal consumables: The main consumables are assist gas (e.g., nitrogen or oxygen), which generally have lower costs than plasma gas mixtures, protective lenses and nozzles as per the usage of the operator.

- Longer lifespan of laser sources: Fiber laser generators last up to 100,000 hours, reducing the need for frequent replacements and lowering maintenance costs.

- Energy efficiency: Fiber lasers convert more electrical energy into cutting power, significantly reducing electricity consumption compared to plasma cutters.

Moreover, fiber laser cutting produces cleaner edges and higher precision, reducing the need for extensive post-processing, which further lowers labor and material waste costs.

Which is More Cost-Effective?

For businesses that primarily cut thick materials (above 25mm), plasma cutting remains a cost-effective option due to its lower initial investment and ability to handle heavy-duty applications. However, for manufacturers prioritizing precision, efficiency, and long-term savings, fiber laser cutting is the better investment due to lower maintenance costs, higher accuracy, and reduced material waste, making it the preferred choice in industries that demand high precision. To know in detail, reach out to our expert at +91 9925036495 today.

What are the Maintenance and Long-Term Expenses of plasma and fiber laser cutting?

Plasma systems need regular replacement of consumables, increasing long-term costs. The frequent wear of electrodes and nozzles adds to maintenance expenses.

Fiber lasers require minimal maintenance due to fewer moving parts. This leads to a lower total cost of ownership over time.

Material Compatibility

Suitable Materials for Plasma vs Fiber Laser

- Plasma Cutting: Ideal for cutting ultra thick metals, including mild steel, stainless steel, aluminum, copper, and brass.

- Fiber Laser Cutting: Best for thin – medium – thick – thickness metals like stainless steel, aluminum, carbon steel and many more with high precision.

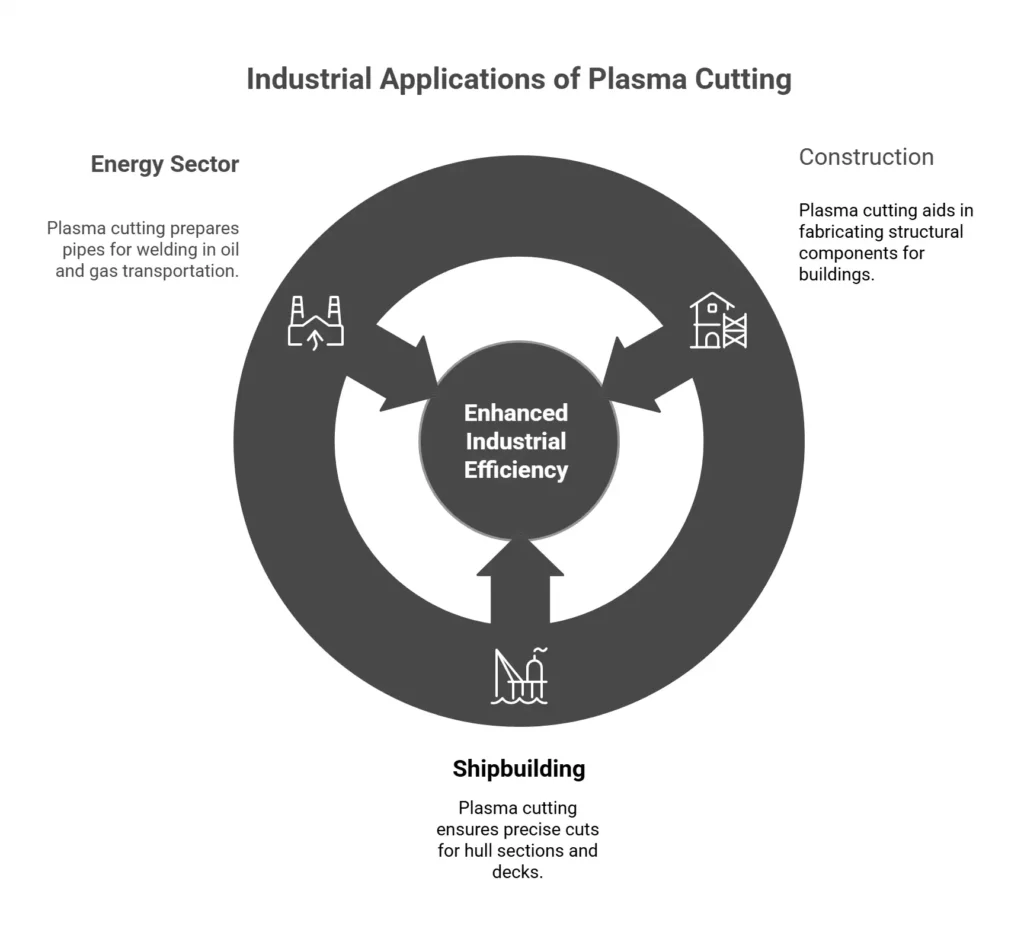

What are the Applications of Plasma Cutting in different Industries?

Here are the diverse industrial applications of plasma cutting across various sectors.

- Construction and Heavy Equipment Manufacturing

In construction, plasma cutting is instrumental in fabricating structural components like beams and columns. Its ability to swiftly cut through thick metals enhances efficiency in building frameworks and heavy machinery production. Manufacturers utilize plasma cutting to shape robust parts such as gears and housings, essential for machinery enduring high stress in industrial environments. - Shipbuilding and Offshore Industries

The shipbuilding sector relies on plasma cutting for its capacity to handle large steel plates and complex geometries. This technology facilitates the precise cutting of hull sections, decks, and other critical components, ensuring structural integrity and adherence to stringent safety standards. Additionally, plasma cutting is employed in offshore industries for constructing and maintaining oil platforms and subsea structures, where durability and precision are paramount. - Pipeline and Energy Sectors

In the energy sector, particularly within pipeline construction and maintenance, plasma cutting is utilized to cut and prepare pipes for welding. Its efficiency and ability to produce clean cuts make it suitable for handling the thick-walled pipes commonly used in oil and gas transportation.

What are the Applications of Fiber Laser Cutting in different Industries?

Here are the diverse industrial applications of fiber laser cutting across various sectors.

- Automotive Industry

Fiber laser cutting is extensively adopted in the automotive industry due to its precision and speed. It’s employed in cutting intricate components such as body panels, chassis parts, and intricate designs, contributing to vehicle light-weighting and fuel efficiency. The technology’s high accuracy ensures minimal material waste and consistent quality in mass production. - Aerospace Sector

In aerospace, the demand for precision and reliability makes fiber laser cutting indispensable. It’s used to fabricate components like turbine blades, structural elements, and intricate brackets from materials such as titanium and aluminum alloys. The technology’s ability to produce clean cuts with tight tolerances ensures the performance and safety of aerospace components. - Electronics Industry

Fiber laser cutting supports the electronics industry by accurately processing delicate, thin materials. It’s widely used to cut components like circuit boards, connectors, and micro-parts where precision is vital to maintain functionality in compact devices. - Medical Devices

In the medical field, fiber lasers are used to manufacture surgical tools, implants, and diagnostic components. The technology delivers clean, burr-free edges essential for safety, hygiene, and compliance with strict health regulations. - Precision Sheet Metal Fabrication

Fiber laser cutting is ideal for precision sheet metal fabrication, enabling the creation of complex shapes and designs with high repeatability. This capability is crucial in industries where enclosures and components require exact specifications, and in custom metal fabrication services catering to diverse industrial needs.

In summary, plasma cutting is favored in industries requiring the efficient cutting of ultra thick materials and robust components, such as construction, shipbuilding, and heavy equipment manufacturing. Conversely, fiber laser cutting excels in applications necessitating high precision, intricate designs, and high-quality finishes, making it the preferred choice in the automotive, aerospace, electronics, and medical device sectors.

Advantages and Disadvantages of Both Methods

| Feature | Plasma Cutting | Fiber Laser Cutting |

|---|---|---|

| Speed | Slower | Faster |

| Precision | Less precise, rough edges | High precision, smooth edges |

| Cost | Lower cost | Higher cost |

| Maintenance | Frequent replacement of consumables | Minimal maintenance |

| Material Thickness | Cuts very thick materials | Best for thin – medium – thick metals |

| Industries | Heavy-duty industries | High-precision industries |

| Energy Consumption | Higher due to plasma arc | More energy-efficient |

| Edge Quality | Requires post-processing | Clean, burr-free cuts |

What are the Worker Safety and Environmental Impact of plasma and fiber laser cutting?

Plasma Cutting generates high levels of noise, UV radiation, and fumes. Requires proper ventilation and protective gear for operators.

While Fiber Laser Cutting produces minimal fumes and noise, making it a safer and more environmentally friendly option.

Heat-Affected Zone (HAZ)

Plasma cutting produces a larger heat-affected zone, which may lead to material warping and structural weaknesses. While Fiber laser cutting has a smaller HAZ, reducing thermal distortion and preserving material integrity.

Which One is Best for Different Use Cases?

- Choose Plasma Cutting if you need an affordable solution for cutting thicker metals with moderate precision, especially for construction, shipbuilding, and heavy equipment.

- Choose Fiber Laser Cutting if you prioritize speed, precision, and efficiency for thin – medium – thick, thickness metals, particularly for applications in automotive, aerospace, and electronics.

Recommendations Based on Budget and Industry Needs

- Budget-Conscious Buyers: Plasma cutting offers a cost-effective entry point for metal fabrication.

- High-Precision Manufacturing: Fiber laser cutting is ideal for industries requiring superior accuracy and minimal finishing work.

- By understanding these key differences, you can make an informed decision on the best cutting technology for your needs.

Conclusion

When comparing plasma cutting and fiber laser cutting, fiber laser cutting emerges as the superior choice for modern manufacturing. With its exceptional precision, faster cutting speeds, lower operating costs, and minimal post-processing requirements, fiber laser technology is revolutionizing industries like automotive, aerospace, electronics, and medical manufacturing.

Unlike plasma cutting, which struggles with fine details and requires more maintenance, fiber laser cutting delivers cleaner edges, higher efficiency, and greater energy savings. Additionally, its ability to cut reflective metals like copper and brass without damage gives it a significant advantage over plasma.

For businesses looking to optimize productivity, reduce material waste, and achieve the highest level of precision, investing in a fiber laser cutting machine is the future-proof choice. If you’re planning to upgrade your operations with a laser cutting machine, contact us today at +91 9925036495 or explore our fiber laser solutions. Our team will be happy to guide you toward the best system for your needs.