SLTL delivers advanced laser cutting solutions for Coimbatore’s pump, textile, and precision engineering industries, boosting productivity, precision, and smart manufacturing across key industrial clusters.

Coimbatore-Tamil Nadu’s industrial powerhouse-has earned many titles over time: The Pump City of India, Manchester of South India, and A Rising Precision Engineering Hub. But beyond these titles lies a bustling manufacturing ecosystem spread across Peelamedu, Ganapathy, SIDCO, Kurichi, Ettimadai, and surrounding industrial belts. These zones collectively drive India’s output in textile machinery, water pumps, automotive components, fabrication, and CNC machining.

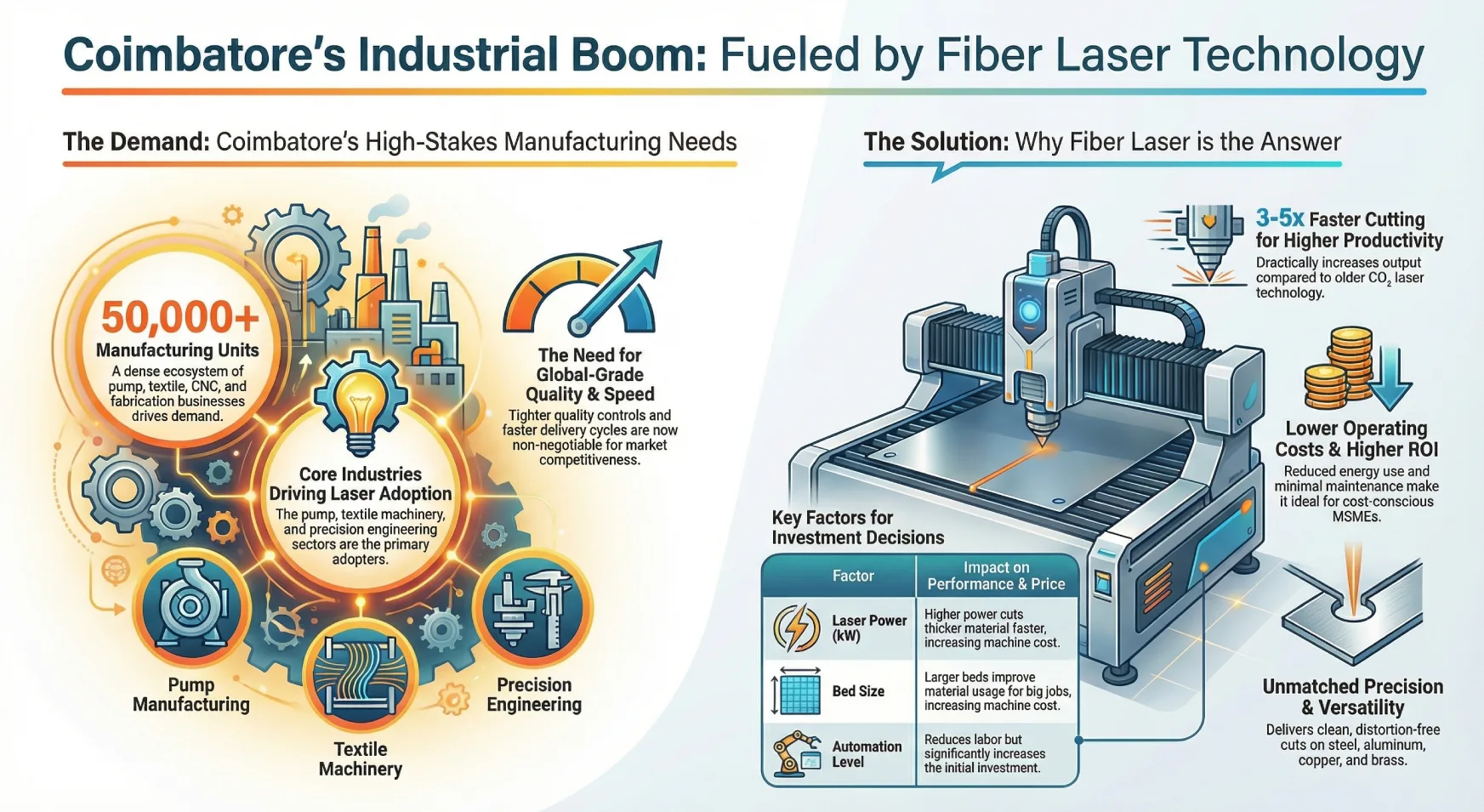

As global markets demand tighter quality controls, faster delivery cycles, and energy-efficient manufacturing, industrial units in Coimbatore are rapidly adopting fiber laser cutting technology. Whether the requirement is for metal laser cutting machines, 2D laser cutting machines, tube laser cutting machines, or sheet metal laser cutting machines, the region’s industries are witnessing a technological transformation.

With IMTEX Forming 2026 approaching, SLTL Group-India’s premier laser systems leader-comes prepared to demonstrate how its latest innovations can elevate Coimbatore’s manufacturing standards across sectors.

This blog explores Coimbatore’s industrial needs, why fiber laser systems are gaining momentum in the region, and how SLTL’s laser cutting solutions align with the city’s growth trajectory.

1. Coimbatore: A Fast-Emerging Engineering & Precision Manufacturing Giant

Coimbatore’s industrial strength is built on:

- 50,000+ MSMEs across fabrication, pump making, CNC machining, and textile machinery

- Strong vendor networks supporting automotive, aerospace, defence, textile, and heavy engineering

- An expanding base of sheet metal fabrication units in Peelamedu, Ganapathy & Kurichi

- Technical institutes producing skilled engineering talent

- A rising trend of automation & Industry 4.0 adoption

This industrial density accelerates demand for laser cutting machines in Coimbatore, which deliver the precision, speed, and efficiency required for modern production.

2. Industry Clusters Driving Laser Adoption in Coimbatore

2.1 Pump Manufacturing Cluster

Coimbatore produces over 40% of India’s pumps-a sector that demands high-precision components such as:

- Pump housings

- Impeller plates

- Motor frames

- Valve bodies

- Stainless steel and mild steel brackets

Manufacturers here have increasingly shifted to fiber laser cutting machines due to their capability to produce corrosion-resistant, dimensionally accurate components with minimal rework.

2.2 Textile Machinery & Automation Sector

Coimbatore’s textile legacy has expanded into advanced machine-building and automation systems. This sector requires:

- Guard plates

- Sheet metal panels

- Machine frames

- Precision brackets

- Prototype components

A CNC laser cutting machine ensures burr-free cutting, smooth finishes, and faster prototyping-allowing textile OEMs to constantly innovate.

2.3 Precision Engineering & CNC Job Shops

The city hosts hundreds of CNC machining units catering to:

- Automotive ancillaries

- Aerospace component suppliers

- Defence manufacturing

- Engineering project companies

These units rely on metal laser cutting in Coimbatore for producing high-tolerance sheet metal parts, jigs, fixtures, and enclosures.

3. Industrial Zones Where Laser Cutting Demand Is Surging

- Peelamedu Industrial Area: Home to engineering workshops and machine builders who require high-accuracy sheet metal laser cutting machines.

- Ganapathy Industrial Zone: A dense fabrication market where job-working units and small workshops invest in robust fiber laser machines to expand their capabilities.

- Kurichi Industrial Estate: Pump makers and component manufacturers here depend on reliable, fast-turnaround MS laser cutting in Coimbatore.

- SIDCO Industrial Estate: An MSME-heavy area with strong adoption of laser cutting machine Coimbatore solutions due to demand from OEM suppliers.

- Ettimadai Industrial Cluster: A rising hub for machinery fabrication, structural steel works, and export-grade production-all of which benefit from 2D and tube laser cutting machines.

4. Why Coimbatore Is Rapidly Transitioning to Fiber Laser Technology

4.1 High Productivity at Lower Operating Costs

Fiber lasers consume far less energy and require minimal maintenance compared to CO₂ lasers-making them ideal for MSMEs concerned about the laser cutting Coimbatore price list.

4.2 Speed & Precision

Fiber lasers deliver cutting speeds 3-5x faster, with unmatched repeatability-suited for pump and textile component production.

4.3 Multi-Material Capabilities

From stainless steel to aluminum and even copper/brass, modern laser cutting machines in Coimbatore must handle diverse material demands.

4.4 No Distortion & Clean Cuts

Fine kerf, smooth edges, and low heat-affected zones reduce post-processing time.

5. SLTL Group at IMTEX Forming 2026: Tailoring Technology for Coimbatore

SLTL Group is set to unveil an array of future-ready laser systems designed to benefit industries across Tamil Nadu.

5.1 2D Fiber Laser Cutting Machines

- High-power cutting engines

- Intelligent auto-focus heads

- Higher sheet utilization

- Compact footprint for small workshops

Ideal for flatbed laser cutting machine manufacturers and job-working units.

5.2 Tube Laser Cutting Systems

For automation, pump frames, machinery structures, and fabrication units, SLTL introduces advanced tube laser cutting machines that perform:

- Slotting

- Notching

- Chamfering

- Angle cuts

All in a single setup.

5.3 Automation & Single Pallet Solutions

Designed for Coimbatore’s MSMEs:

- Single-pallet machines for compact shops

- Robotic handling systems for larger factories

- Material management automation

This enables lower labour dependency and higher productivity.

5.4 Industry 4.0-Enabled Systems

- Real-time monitoring

- Predictive maintenance

- Process analytics

Matching Coimbatore’s growing inclination toward smart manufacturing.

6. Understanding Laser Cutting Machine Price in Coimbatore

The laser cutting machine price in Coimbatore varies based on several technical and operational factors. Manufacturers across Peelamedu, Ganapathy, SIDCO, Kurichi, and Ettimadai often evaluate machines not just on upfront cost, but on long-term performance, running expenses, and return on investment.

Below is a deeper look at what influences pricing and why SLTL’s solutions offer superior value.

6.1 Key Factors That Determine Laser Cutting Machine Price

- Laser Power (1kW to 30kW+)

Laser power directly influences:

- Cutting speed

- Material thickness capacity

- Production volume capability

In Coimbatore, pump manufacturers and precision engineering units often choose 2-6kW systems, while heavy fabrication and OEM exporters may require 8-12kW or even high-power 20kW+ models.

Higher wattage increases machine price, but significantly boosts throughput and reduces per-part cost.

- Bed Size & Machine Format

Common bed sizes include:

- 1515, 3015 laser cutting machine (ideal for MSMEs and small workshops)

Compact formats suited for limited shopfloor space and everyday fabrication needs. Perfect for precise cutting of standard sheet sizes with low operating cost.

- 4020 laser cutting machine

Offers a larger working area for improved sheet nesting and higher batch productivity. A reliable choice for growing fabrication units handling diverse materials.

- 6520, 6525, 8025 laser cutting machine (preferred by high-volume fabricators)

Designed for heavy-duty, continuous manufacturing with maximum sheet utilization. Supports automation, bulk loading, and long production cycles without downtime.

Larger beds allow sheet nesting, bulk loading, and uninterrupted production-key for fabrication units in Ganapathy and Kurichi.

- Automation Level

Automation can increase initial cost but drastically improves productivity:

- Manual sheet loading machines: Entry-level, lower price

- Single pallet models: Best for compact Coimbatore workshops

- Automatic shuttle tables: Reduce changeover time

- Robotic loading/unloading: Ideal for OEMs and mass production

- Material storage towers: Continuous flow for large factories

Automation reduces labour dependency-a major concern in SIDCO and Peelamedu industries.

- Material Usage & Application Requirements

Price varies based on what materials a machine is optimized for:

- Mild Steel

- Stainless Steel

- Aluminum

- Copper

- Brass

Cutting reflective materials requires advanced technology and stable beam delivery, which may slightly influence machine cost.

SLTL designs its systems to handle all these materials with minimal setup changes, offering better versatility for Coimbatore’s mixed-industry ecosystem.

- Required Cutting Thickness

- Thicker materials require:

- Higher wattage

- More robust machine frames

- Advanced cooling systems

- Heavy-duty cutting heads

Pump body manufacturers, fabrication shops, and machine builders often require 8-25mm thickness cutting, which affects machine specifications and pricing.

6.2 Why SLTL Offers the Best Ownership value in Coimbatore

Price is only meaningful when evaluated alongside long-term benefits. SLTL ensures that every customer-whether an MSME or a large OEM-gets the maximum value throughout the machine’s life cycle.

Transparent & Fair Pricing Structure

SLTL clearly explains:

- Machine cost

- Optional features

- Automation upgrades

- Expected maintenance expenses

- Power consumption

There are no hidden charges-making it easier for Coimbatore companies to plan capital investments.

Long-Term Support & Service Reliability

With dedicated service teams in Tamil Nadu, SLTL ensures:

- Fast breakdown resolution

- Regular preventive maintenance

- On-site training

- Application support

This reduces downtime and enhances machine productivity-an essential factor for high-demand sectors like pumps and textile machinery.

Readily Available Spare Parts

SLTL maintains spare part availability to ensure:

- Zero production delays

- Quick replacement

- Smooth running of day-to-day operations

For Coimbatore’s fabrication and CNC job-work units, this is a critical advantage.

Lower Cost-Per-Part Over Machine Lifetime

SLTL lasers are engineered for:

- Lower electricity consumption

- Minimal consumable usage

- High cutting speeds

- Long machine lifespan

Even if the upfront cost is similar to competitors, the lifetime running cost is significantly lower, ensuring a strong return on investment.

Scalability & Upgradability

As your business grows, SLTL machines can be enhanced with:

- Higher wattage sources

- Automated loading/unloading

- Software upgrades

- Material handling modules

This future-proofing helps Coimbatore manufacturers remain competitive for years to come.

7. How Laser Cutting Boosts Competitiveness for Coimbatore Industries

✔ Faster turnaround time

✔ Reduced rework & waste

✔ Enhanced production capacity

✔ Export-grade component quality

✔ Increased profitability for fabrication shops

✔ Freedom to handle diversified product portfolios

Laser cutting technology strengthens Coimbatore’s position in global supply chains.

8. SLTL’s Regional Advantage for Tamil Nadu Industries

SLTL supports Coimbatore’s fabricators and OEMs with:

- Local after-sales teams

- On-site operator training

- Application-level assistance

- Quick spare availability

- Custom-configured machines

This ensures customers in Peelamedu, Ganapathy, SIDCO, Kurichi, and Ettimadai receive continuous operational support.

9. Why Coimbatore Manufacturers Should Visit SLTL at IMTEX 2026

Visitors will witness:

- Live cutting demos

- Consultations with technical experts

- ROI calculations

- Industry-specific machine recommendations

- Automation assessment

- Upgrades for existing machinery

It’s the ideal platform for businesses planning capacity expansion or modernization.

10. How SLTL Laser Solutions Empower Coimbatore’s Pump, Textile & Precision Engineering Clusters

This section integrates your earlier requirement-expanding how SLTL directly helps local industries.

10.1 Supporting Coimbatore’s Pump & Motor Manufacturing Sector

SLTL lasers deliver:

✔ High-speed SS/MS cutting: Ideal for impellers, casings, and pump brackets.

✔ ±0.02 mm precision: Ensuring leak-proof assemblies and enhanced efficiency.

✔ Lower rejection & scrap: Crucial for high-volume manufacturers.

✔ Low operating costs: Suitable for MSMEs working on thin profit margins.

10.2 Empowering Textile Machinery & Automation Companies

SLTL provides:

✔ Burr-free components: Essential for machine guards and frames.

✔ Rapid prototyping: Supporting Coimbatore’s innovation-driven textile equipment sector.

✔ Strong structural component cutting: Improving durability and reliability of automation systems.

10.3 Enabling CNC Job Shops & Precision Engineering Units

With SLTL, CNC workshops benefit from:

✔ Micron-level accuracy: Perfect for instrument housings and enclosures.

✔ Repeatability for large batches: Meeting OEM expectations consistently.

✔ Flexibility across mixed material jobs: MS, SS, aluminum, copper, brass-all with seamless switching.

10.4 Tube Laser Solutions for Machinery, Fabrication & Automation

SLTL’s tube lasers offer:

✔ Perfect angle cutting & notch accuracy

✔ Chamfering & porting in a single setup

✔ Rapid processing for pump bases & machine frames

Helping industries reduce fabrication time dramatically.

10.5 Automation for Coimbatore’s Growing MSMEs

SLTL automation brings:

- Robotic loading/unloading

- Compact single-pallet solutions

- Material handling conveyors

- Industry 4.0 dashboards

Addressing labour shortages and boosting output.

10.6 Lower Cost Per Part for Fabrication Units

SLTL’s efficiency means:

- Higher output per hour

- Minimal consumable usage

- Longer machine life

- Reduced manpower requirement

Ensuring competitive pricing for laser cutting Coimbatore businesses.

10.7 Local Training, Service & Support

SLTL ensures:

- Immediate service response

- On-ground training

- Application trials

- Quick spare delivery

This is especially valuable for fast-growing industrial clusters.

10.8 Future-Proofing Coimbatore’s Manufacturing Ecosystem

SLTL machines support:

- Power upgrades

- Automation add-ons

- Software enhancements

- Remote diagnostics

Ensuring Coimbatore’s manufacturers remain competitive for the next decade.

11. Conclusion: SLTL & Coimbatore-Driving the Next Era of Fabrication Excellence

Coimbatore’s industrial sectors-pump manufacturing, textile machinery, engineering, and fabrication-are rapidly evolving. Precision, speed, and global-grade manufacturing quality have become non-negotiable.

SLTL Group’s advanced laser cutting machines in Coimbatore provide:

- Superior build quality

- High-speed production

- Low-cost operations

- Local support

- Industry 4.0 compatibility

Whether you need 2D laser machines, tube laser cutting systems, single pallet machines, or fully automated setups, SLTL is the ideal technology partner for industries in Peelamedu, Ganapathy, Kurichi, SIDCO, Ettimadai and beyond.

As Coimbatore continues its journey toward becoming a globally recognized engineering hub, SLTL stands ready with solutions that empower innovation, productivity, and long-term competitiveness.