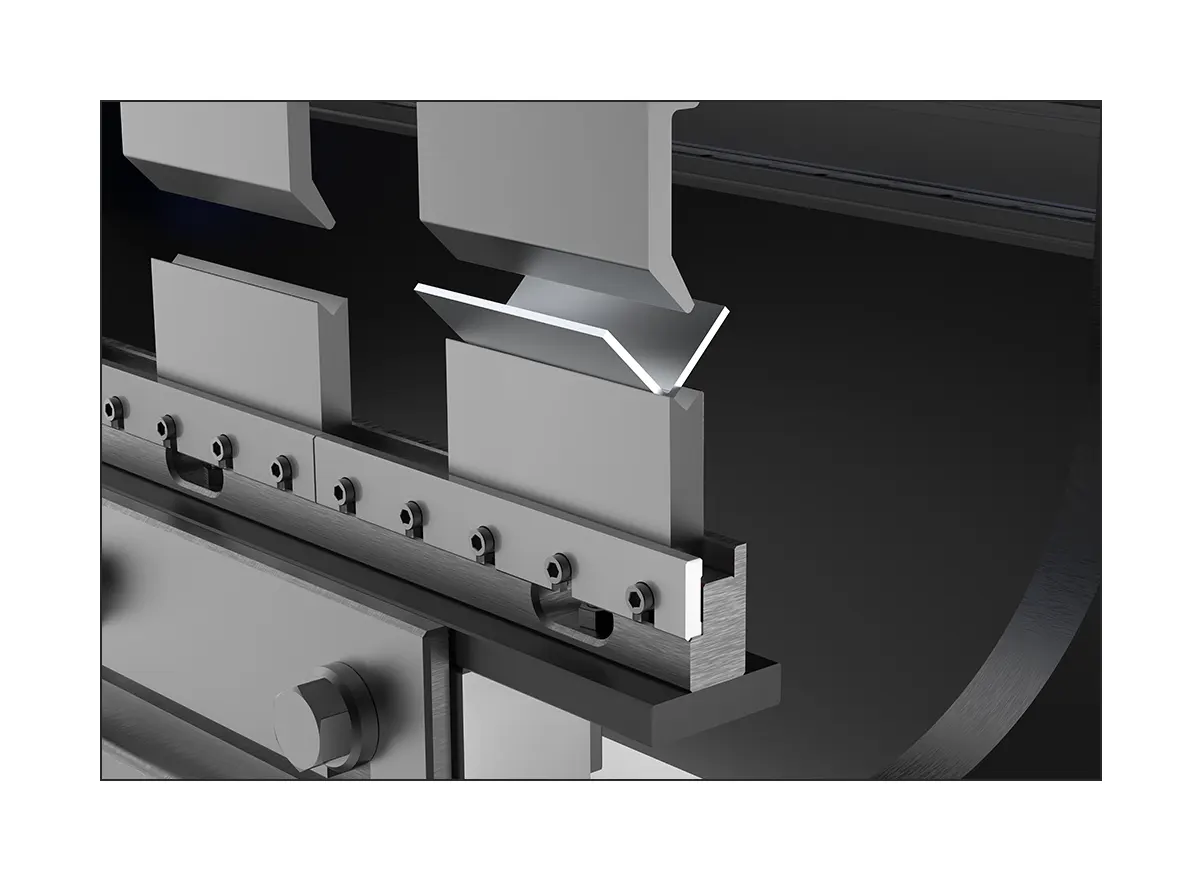

SLTL Group’s baseline Machines are designed to provide value for money in the market. We have always been innovating to help industry and fabricators achieve the highest standards of applications. The speciality of this system gives the flexibility to process any simple to complex components. The key element of Opti Bend is to create basic shapes or complex geometrical structures with a similar level of precision. Each model of Opti Bend has built up an appropriate system for parallel plate bending, a basic component to ensure a consistent bending angle without the need for any extra delegated systems. It simulates in three dimensions and allows for manual or automatic search of the bending sequence for the presses to be robotic. Other innovations include the angle-measuring system with the interface for bending data correction and a brand new tool clamping system for a dramatic reduction in setup time.

Ever since incorporation, we have been making our own way through futuristic technology and ground-breaking innovations.

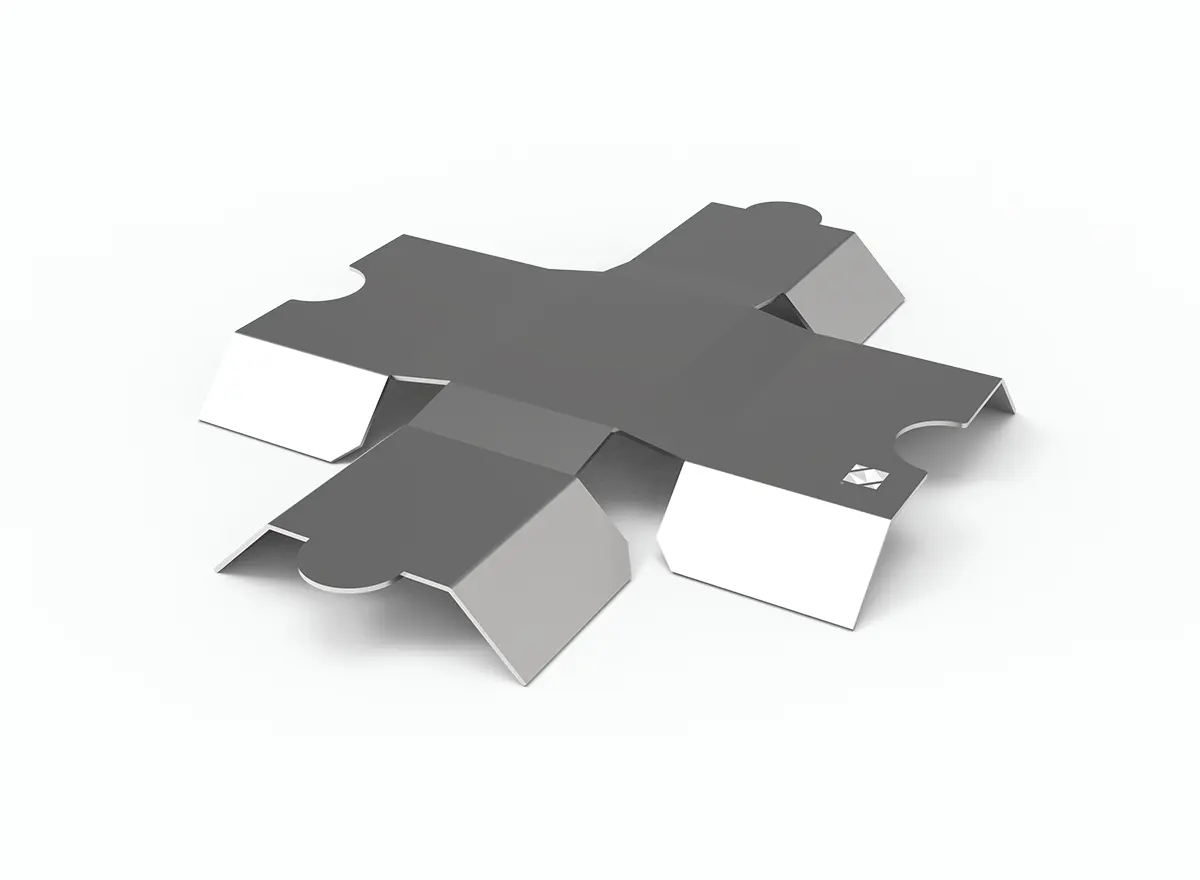

It is an industrial sheet metal bending machine which creates basic to complex geometrical structures with the finest precision.

With high process accuracy, the machine gives perfect bending to the material and gives the exact shape as required. It works well even on larger components giving a perfect edge.

With Conical and radius bending processes it gives perfect angle to material.The bending machine is fitted with a clamping system, which holds the plate in position for better accuracy giving quality outcomes.

The automation mechanism helps in very easy operation and proves to be a less labour-intensive machine. The machine can be simply operated as it is exceptionally easy to understand and have a profoundly great controlling framework.

These excellent machines for bending metal save time with the most advanced structures, as a great deal of time is consumed when metal bending is done manually. Therefore, metal bending machines encourage the company to process more components within less time resulting in less overhead costs.

With the help of OptiBend, all the required parts can be effortlessly modified and quickly manufactured by semi-skilled operators. Considerably the generic functions and programming procedures of the machine can be learned and practically implemented for the most effective results in lesser time.

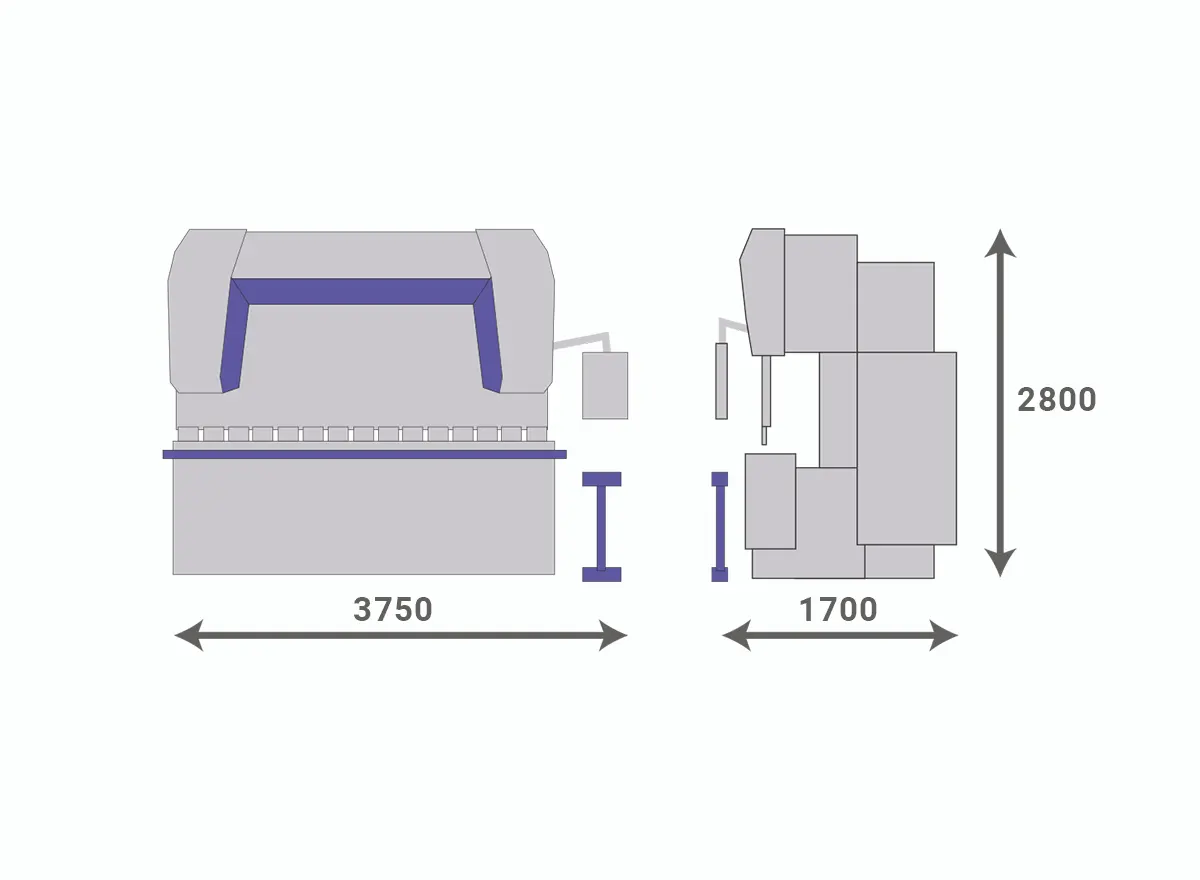

| Model | PBO 1030 | PBO 1040 | PBO 1630 | PBO 1640 | PBO 2030 | PBO 2040 |

|---|---|---|---|---|---|---|

| Maximum Tonnage | 100 | 100 | 160 | 160 | 200 | 200 |

| Table length (Working length) | 90 × 3100 | 90 × 4100 | 90 × 3100 | 90 × 4100 | 90 × 3100 | 90 × 4100 |

| Working height (mm) | 900 | 900 | 900 | 900 | 900 | 900 |

| Open Daylight (mm) | 350 | 350 | 410 | 410 | 410 | 410 |

| Close Daylight (mm) | 200 | 200 | 210 | 210 | 210 | 210 |

| Ram Stroke (mm) | 150 | 150 | 200 | 200 | 200 | 200 |

| Bending Capacity in M.S. | 4 × 3000 | 3 × 4000 | 6 × 3000 | 5 × 4000 | 8 × 3000 | 6 × 4000 |

| Ram Speed (mm/sec) | ||||||

| Approach | 100 | 100 | 100 | 100 | 100 | 100 |

| Pressing | 7 | 7 | 7 | 7 | 6 | 6 |

| Return | 80 | 80 | 80 | 80 | 80 | 80 |

| Throat Depth(mm) | 200 | 200 | 300 | 300 | 300 | 300 |

| Oil capacity (litre) | 300 | 300 | 500 | 500 | 500 | 500 |

| Motor HP | 10 | 10 | 15 | 15 | 20 | 20 |

| Overall Dimension (mm) | ||||||

| Length A | 3750 | 4750 | 3750 | 4800 | 3800 | 4800 |

| Width B | 1700 | 1850 | 1800 | 1900 | 1900 | 2000 |

| Height C | 2800 | 3000 | 2900 | 3200 | 3000 | 3250 |

| Machine Weight (Kg.) | 5700 | 7000 | 6500 | 7600 | 7500 | 8500 |

| Controller- Delem DA 56S | YES | YES | YES | YES | YES | YES |

Support

Service Response 100%

Physical Response

Delighted Customers

Interested In a Product?

Pricing, Technical Data & More

Explore our blogs for a resourceful insight into the infinite opportunities of the laser world.

With the intervention of technology SLTL Group has led the way through futuristic solutions and taken the National legacy to foreign land

We've got the vision to deliver continuous innovation, working in the future.

As technology improves and changes are done at a quick pace, the industry is reaching new heights.

24*7 service support and technical assistance. You’re welcome to visit our office for other insights

E-30, Electronic Estate, G. I. D. C.,

Sector - 26, Gandhinagar - 382 028

Gujarat, India.