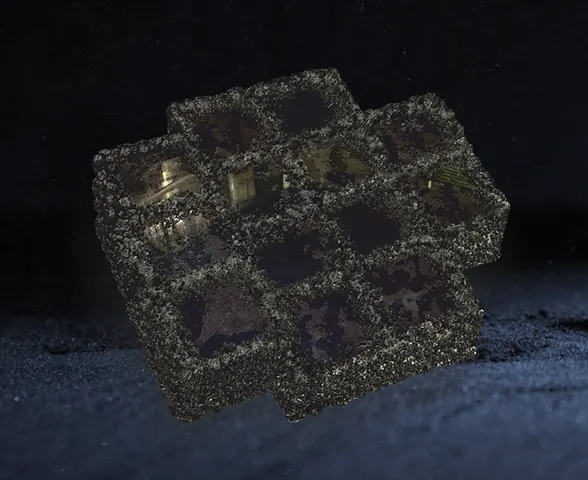

SLTL Group is known for the pioneering diamond industry with the introduction of fiber laser technology for diamond processing. With the increase in demand for processing of lab-grown or CVD diamond SLTL Group is presenting Hallmark – Lab plus. This machine is developed by company’s in-house R&D team to perform specific tasks like Coring and Slicing for CVD diamonds. Labplus is precise, productive and powerful laser system designed to process CVD diamonds.

Ever since incorporation, we have been making our own way through futuristic technology and ground-breaking innovations.

Developed by in-house R&D team, a precise productive and power machine design to process CVD (Lab-grown) diamonds.

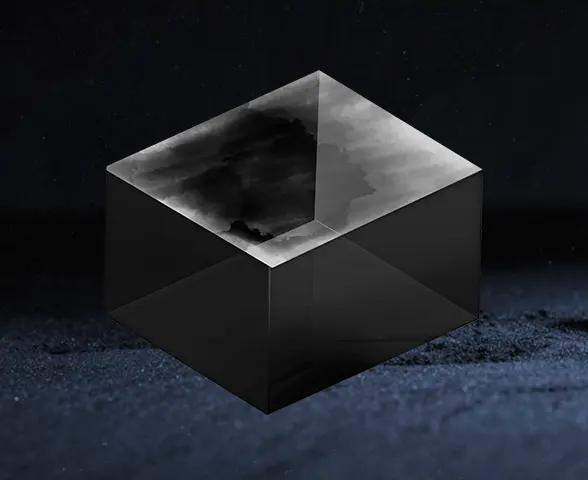

Lab Plus is equipped with the advanced laser which allows producing flat cuts ( without taper ) while coring of rough CVD diamond. This results in obtaining smooth shape with no or less wastage of material.

With Lab Plus’s software guided precision laser beam, it produces an excellent or even surface finished during the coring process. This benefits in saving of time and edging process is eliminated.

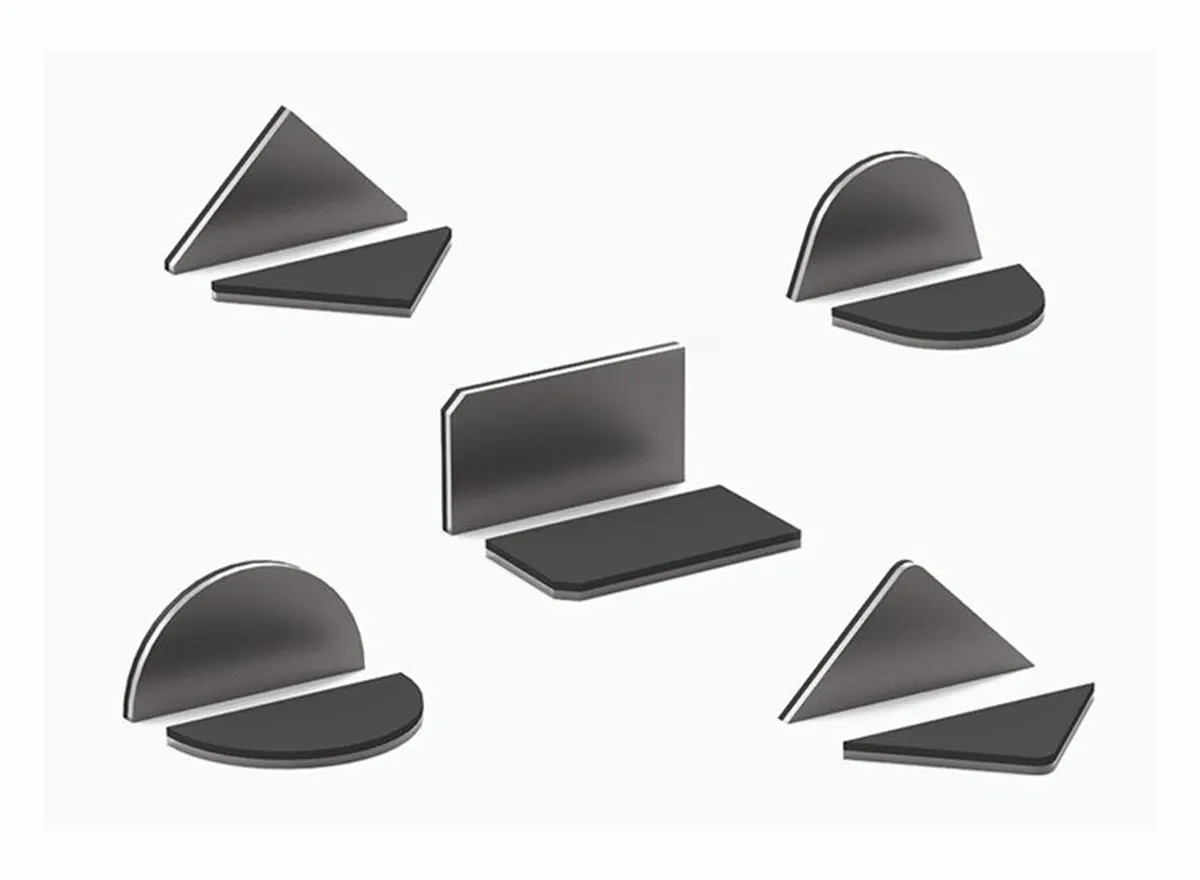

With these systems, coring of the CVD diamond could be obtained in the desired shape like round, square, rectangle and more with flawless quality.

With the use of fiber laser technology, the output provided by the system is excellent and the system requires less maintenance.

These processing systems are equipped with advanced technologies to reduce human intervention for quality purpose.

The machine is integrated with in-house developed intuitive smart software. This software guides the laser beam to process diamond without breaking it.

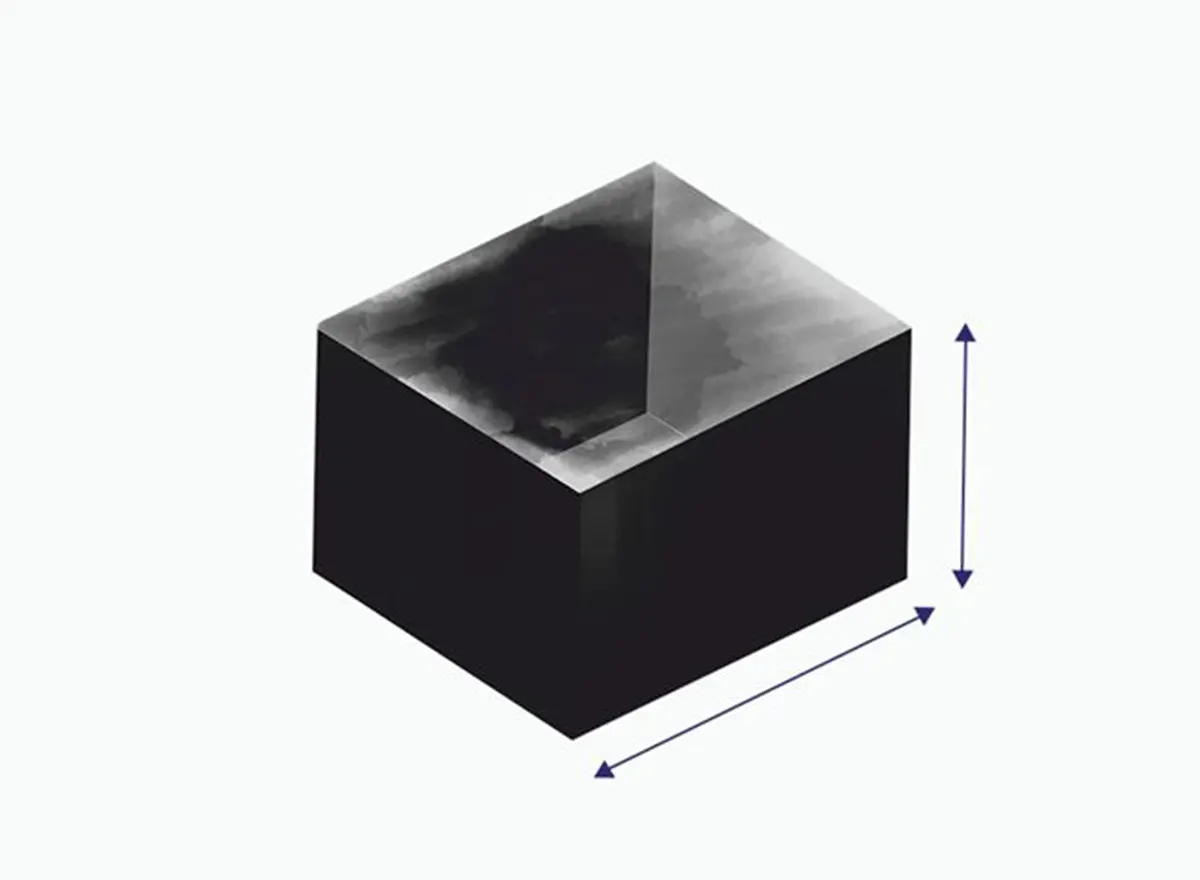

| Model | Hallmark Labplus | |

|---|---|---|

| Laser Source | SPAQ 75W CW | |

| Laser Type | DPSSL | |

| Wave Length | nm | 1064 |

| Beam Mode | TEM | |

| Working Power | watt | 4 18 |

| CNC Table | mm | 170 170 |

| Resolution | micron | 1 |

| Repeatability | micron | 3 |

| Accuracy | micron | 2 |

| Drive Type | AC SERVO | |

| Z Axis Travel | mm | 50 |

| Power Supply | 1 Phase, 15 Amp | |

| Power Consumption | kW | 1.7 |

| Temperature / Humidity | Celsius | 20 30 / < 60% |

| Coolant Requirement | It/hr | 4 6 |

| Dimension (L*D*H) | mm | 1725 * 990 1610 |

| Computer System | Intel Core, 1 GB, 160 GB HDD, 17″ LCD |

*Technical Specifications are subject to change without prior notice

Support

Online Service Response 100%

Physical Response

Delighted Customers

Interested In a Product?

Pricing, Technical Data & More

Explore our blogs for a resourceful insight into the infinite opportunities of the laser world.

The terms ‘Lab-grown’, ‘CVD’ or ‘Synthetic’ Diamonds have rung over our ears for quite some time now.

The laser machines brought a revolutionary change in the Diamond Market.

Using the latest art optical lens technology made from high-grade materials; LOTUS is the full range of diamond planning & marking solution and used to confidently plan for rough diamonds.

24*7 service support and technical assistance. You’re welcome to visit our office for other insights

E-30, Electronic Estate, G. I. D. C.,

Sector - 26, Gandhinagar - 382 028

Gujarat, India.