Spanning a legacy of more than 5000 years, Indian Jewellery is evident for the country’s aesthetic and the cultural history.

SLTL’s Extraordinary Jewellery Making Technology Range For Hassle Free Jewel Crafting.

Spanning a legacy of more than 5000 years, Indian Jewellery is evident for the country’s aesthetic and the cultural history. Our sophisticated heritage and the culture is responsible for the continuous growing affection for jewelleries till today. From Kundan designs to Meenakari, India is blooming all over the world for its richness in Jewellery making. The demand of Indian jewellery is huge worldwide. By closely understanding the traditional as well as the conventional methods of jewellery making we have developed many innovative technologies to improve the jewellery making experience.

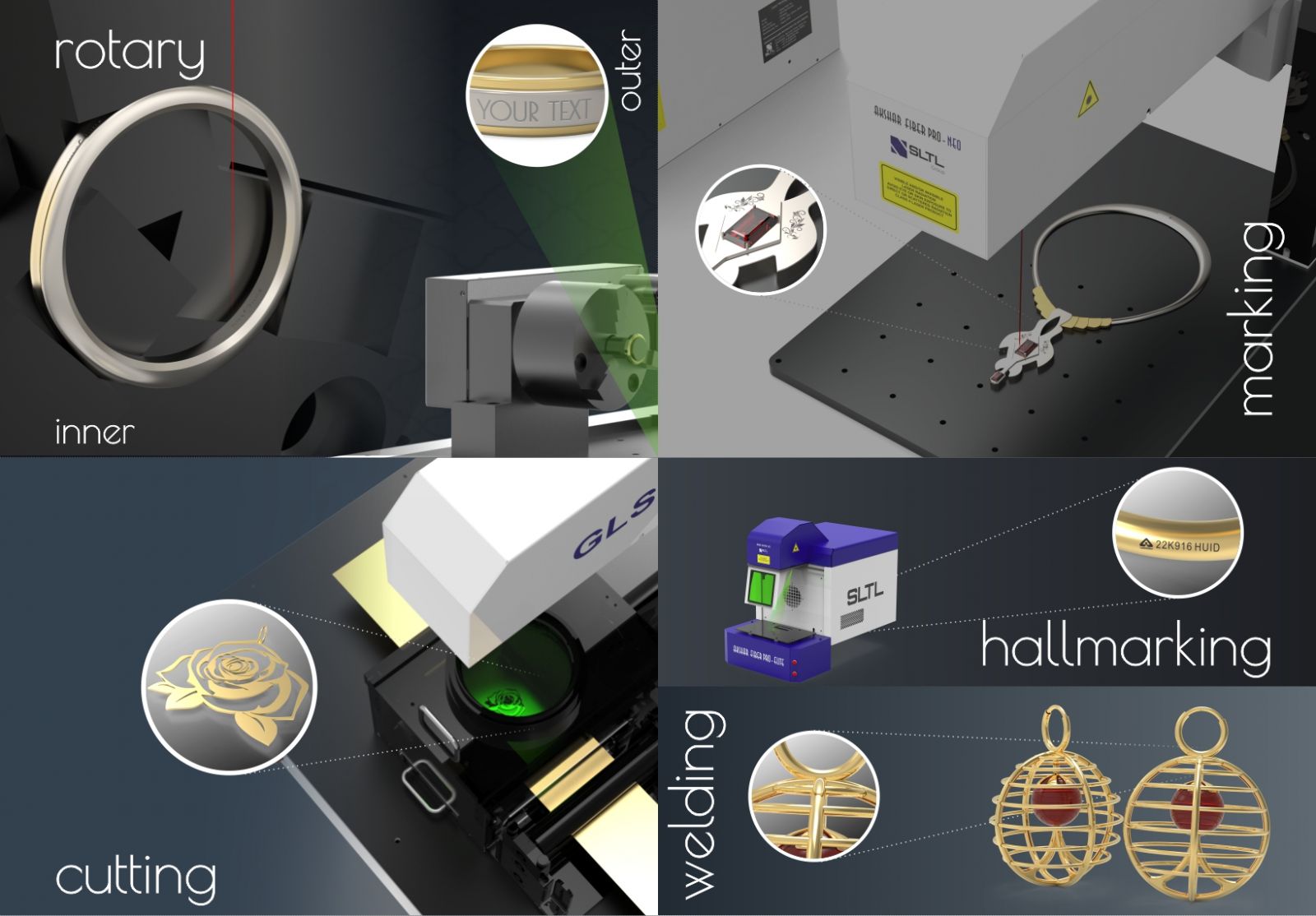

A Smart Technology To Make Jewels Cutting Easier

The first step to craft any jewellery design is to cut it in a particular shape. The cutting is tricky, if you use old methods of cutting it will consume a lot of time and that too without surety of precision and accuracy. Gone are those days when the conventional methods were the only choice to craft jewellery. SLTL has developed the best in class laser jewellery cutting machines and here are 5 benefits to add our solution to your jewellery making journey:

1. Lasers cut with high precision and accuracy.

2. It prevents loss of your precious metal

3. Our lasers can cut designs as fine as filigree

4. It comes with automation to boost repeatability

5. Laser cuttingis quick and does not deform your precious metal

The New-Tech Solution For Marking & Engraving on Jewellery

Fine design on jewellery never goes out of fashion. Inducing minute designs is one of the most sensitive task in jewellery making. Marking and engraving delicate designs is tedious and time consuming with old methods. The demand for beautifully marked designs, names, monograms etc. on precious metal is very high. Our powerful jewellery marking & engraving machine can mark any intricate design in seconds. Here are 5 reasons to use our laser technology for marking and engraving on your precious metals:

1. It leaves clear & smooth finishing

2. It allows you to customize by simply uploading an image to the system.

3. It provides smart automation for precise marking

4. The automation helps to leave fine look and matchless precision.

5. The TTL technology facilitates to process intricate fine designs

6. User-friendly and does not require expertise.

Authenticate Jewellery in Real-Time

The reliable jewellery is the one which has hallmark to prove its authenticity. With the change in jewellery authentication norms, SLTL Group’s team worked to develop a faster automation technology which will help the hall marking industry to gain productivity and save time. The process is quick and facilitates the hallmarking centres with improved functioning. Here are 5 amazing reasons to choose SLTL’s hallmarking solution:

1. It is complied with Industry standards

2. Marking is quick and saves time

3. Automated & provides accurate and precise marking

4. Automated and provides unparalleled accuracy.

5. Trusted by 90% big hallmarking centers for its consistent performance.

6. Hassle-free marking in real-time.

Powerful Welding Solution for Excellent Strength

Welding jewellery with laser is widely accepted technique to join the breakages in jewellery. A small damage can deform or even destroy the design of your precious jewellery, if you use old methods of welding you have to compromise with the look.The new methods mainly, the laser welding techniques is a smart choice to weld the broken surface. Mend gaps with our innovative solution which uses tiny laser spot to fix the broken area without deforming your precious jewellery. Fuse the gap with solder flawlessly.Whether it is bezel setting, prong setting or jewellery repairing our welding technology can fix it all. The best thing is it does not require excessive post-weld treatment. and the finishing cannot be achieved by any other method of welding.

Here are 5 reasons to consider SLTL Group’s Jewellery welding machine:

1. It uses extremely narrow welding area

2. Weld any surface at any angle

3. It does not deform the material

4. Welding operations doesn’t require expertise

5. It gives seamless welding surface with matchless strength

Automation to Pilot Perfection

SLTL provides a perfect customization solution with different accessories attachable with the machine. The automation is the integral part of these machineries. One of the brilliant solution is TTL technology, it facilitates the operator to intricate minute designs with enlarged view. This technology is best suited to design fine jewellery with precision on even micrometers. Customize your finest design to buzz the matchless trendand create your unique designing style.

Moreover, The marking on the circumference of a ring, bangle, bracelet or other round jewellery can be done by the method of rotary marking. The beautiful markings on the circumference can be embarked on both the sides of the jewellery. The inner circumference can be marked with equal precision as the outer circumference is marked. The automation and the smart sensor make it possible to engrave or mark on any surface, any design with high precision and accuracy.

Here are 5 uses of automation in jewellery making:

1. It gives excellent accuracy and precision for repeatability

2. It saves time and manpower

3. It paves a way to innovative designs

4. Caters the new-tech solution.

5. It helps to stay ahead from competitors.

Choosing laser technology makes the jewel crafting easy and economical. SLTL Group have enormous number of solutions for each of the step of jewellery making. From cutting to welding, name the challenge and our team will come up with the best solutions in the industry. Our machinery provides the best practices of jewellery making, with smart technology, it not only saves your precious metal but also gives a matchless smooth finish and fine look. Our excellent range of jewellery making provides various accessories to make the jewellery making better, TTL technology or rotator solution, SLTL provides a 360 degree approach for your jewellery making.

SLTL Group is well known in the international market with clients and partners in more than 30 countries. We always thrive to provide excellent quality with continuous innovation and improvements. We have earned more than 25 patents and still counting. SLTL Group is the pioneer of laser technology and fastest growing innovators to provide better solutions before anyone else.

We are introducing more exciting innovations at IIJS Primere Show, Come & Meet Laser Experts to witness our newer solutions. Hall No. 1 ; Booth No. D013-1C014, Bangalore International Exhibition Centre, Bengaluru, India. Register Now