Advanced - Innovative - Efficient - Fast. These are some of the many terms that we use to define technology. But are they enough to safeguard our future in a way that complements environmental balance?

Advanced – Innovative – Efficient – Fast. These are some of the many terms that we use to define technology. But are they enough to safeguard our future in a way that complements environmental balance?

Surely Not!

With climate change becoming a grave global issue, every machine that is being developed today – regardless of its location – is required to befriend the environment in one way or another.

One of the biggest concerns, therefore, for the modern manufacturing industry is to turn up with environment-friendly technologies. As a result, many large companies are investing extensively in R&D and have made sustainability a part of their brand identity.

If we talk about the Laser Industry, there are so many uses for lasers, from manufacturing cars to material fabrication. It’s staggering how much of an impact lasers have on daily life. Because of this wide use, there has been a dire need for these technologies to be environment-friendly.

Let’s have a look at how the efforts of SLTL Group has made laser technology more environment friendly over other alternatives.

Fiber Laser vs CO2

Till 1997 industry used to use traditional methods for cutting metals, SLTL then developed India’s first CO2 laser cutting machine for metal cutting. But due to its harmful effects on the environment and other challenges we abandoned the technique and began developing a more environment friendly metal cutting technology. This is when SLTL Group became the first-ever company to come up with the Fiber Laser System in India, the patent for which we hold to date.

Hence despite the common goal for which both fiber lasers and CO2 lasers work, following points confirm the environment-friendly nature of

Fiber lasers over CO2, reduced power consumption

- Fiber lasers have better electrical efficiency than CO2 lasers. This makes them more efficient and environmentally friendly due to the benefits of lower running costs.

- Fiber laser cutting’s general energy consumption can be reduced by 70 percent compared to traditional CO2 laser cutting.

- Fiber laser cutting minimizes the operational costs and saves resources.

- Fiber laser offers 50% longer servicing intervals and 50% lower servicing costs.

Negligible Material Wastage with Smart Nesting Software

The level of control that users can hold is what makes SLTLs fiber laser cutting so useful. You’re given total support when it comes to beam length, duration, intensity, and heat output, allowing you to perfectly adapt the beam to the surface that you are working within.

In the area of fiber laser, SLTL Group also came up with ‘Smart Nesting Software’ which is in-house developed software, that has been allowing us to produce less scrap and dumping material. Over the years it has helped the SLTL team reduce material wastage significantly, again making it a more environment-friendly method for cutting metals. Besides, manufacturers are always looking for ways to reduce manufacturing scrap and waste. SLTLs nesting software can help manufacturers reduce their scrap production by improving the number of cut-outs that can be made in a single sheet of metal which also increases efficiency. More cut-outs per sheet mean less wastage of material per sheet. This in turn allows manufacturers to make more quality parts with less total material investment. Besides, manufacturers are always looking for ways to reduce manufacturing scrap and waste. Lasers can help manufacturers reduce their scrap production by improving the number of cut-outs that can be made in a single sheet of metal. More cut-outs per sheet means less wasted material per sheet. This in turn allows manufacturers to make more parts with less total material investment.

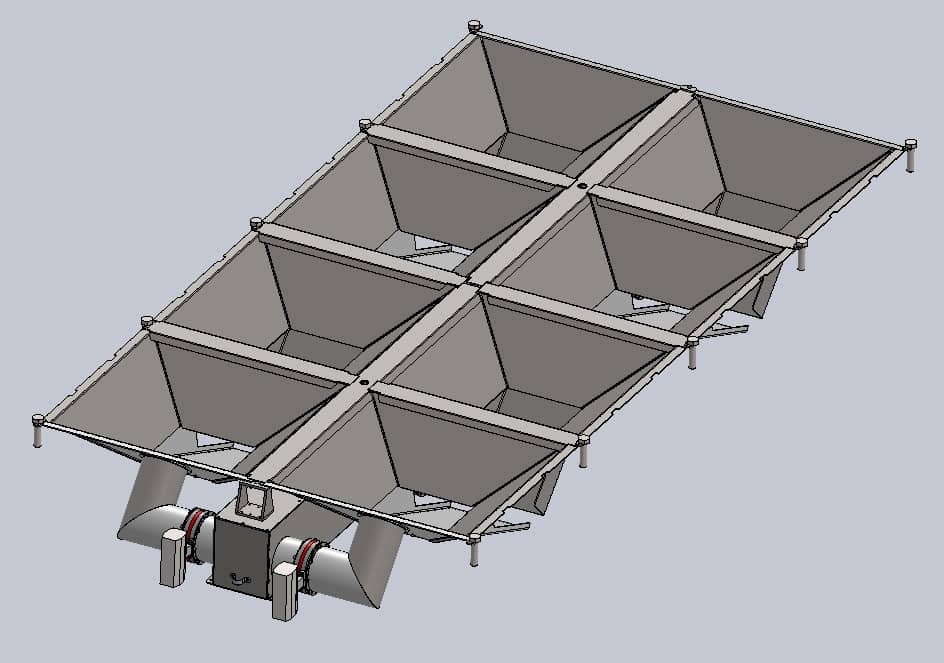

Smart Dynamic Fume Suction

Another such environment-friendly innovation of SLTL Group is its Dynamic Fume Suction which comes with SLTLs Laser Cutting machine. Our experts have divided machine in four zones for optimizing fume suction. What it has done is, it has reduced the volume of fumes that gets generated during the process because suction efficiently works in the zone where the cutting happens, and it remains active for the cutting area, therefore, saving the power consumed significantly.