With firm dedication and creative mindset, SLTL Team has been coming up with breakthroughs since its early years.

With firm dedication and creative mindset, SLTL Team has been coming up with breakthroughs since its early years.

Talking about breakthroughs, on The World Environment Day we want to share two of our highly eco friendly Innovations that have helped us serve the needs of mother nature in the most optimal way possible.

I) Introducing Solar Power Generation

Producing power from waste is one of the best practices industries can adopt for an environment friendly. Therefore at SLTL, we are utilizing an efficient heat pipe exchanger to collect any waste heat from industrial or environmental application units (such as gas turbine/solar trough/municipal waste incineration unit) and for co-generation of electric power and hot water.

For this we have come up with an innovative idea of combining two different technologies together:

i) Generating electric power from waste heat source and

ii) Producing hot water from wasted energy from thermoelectric (TE) modules.

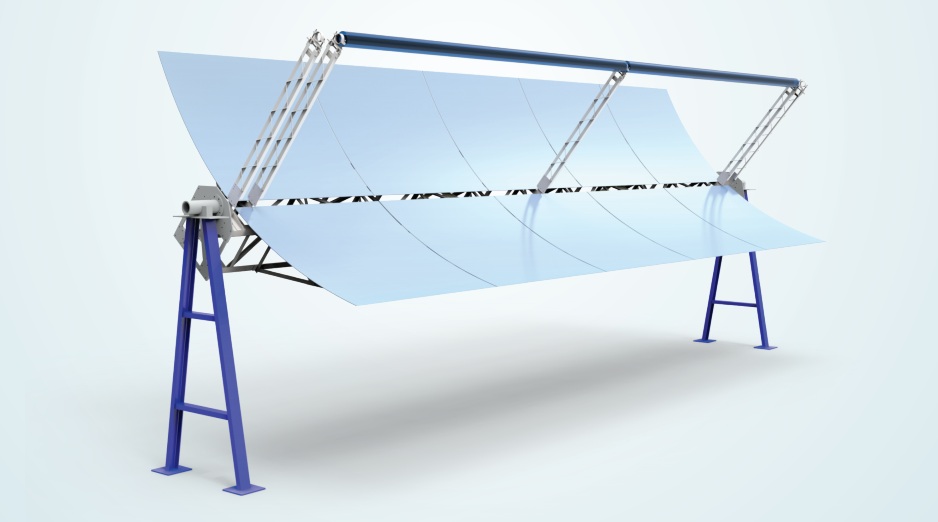

Currently, we are using a parabolic trough collector (for solar heat collection) along with an evacuated heat pipe to transfer energy to a TE transducer, but the system can be well employed for any industrial or domestic waste heat source with a temperature range of 50 – 250°C.

The transferred heat to the transducer is then converted into electricity by TE module at approx. 5% efficiency. The produced power is direct current in nature which is finally converted into alternate current. The waste heat from the transducer is then retrieved through another heat exchanger at around 60°C and the system produces hot water as a byproduct. With a normal solar radiation of 700 W/m2, the net thermal input per trough is 316 W. This input gives around 15 W of electricity and approx. 200 litres of hot water (>50°C) per day. So, the energy conversion efficiency of the overall system is around 85% taking in account electricity and hot water production capacity.

Worldwide different R&D labs along with the industrial sector have worked together to enhance the efficiency of solar photovoltaic (PV) systems, performance of which degrades due to rise in per degree temperature.

SLTL, being an Indian innovative company, has realized early that these systems are not suitable for Indian climatic conditions and so moved towards solar-thermal route. This approach is very unique in nature as the system combines two different technologies of solar heating and solar electricity in one single process. Due to the uniqueness of the system one Indian Patent (No. 337408) is also granted to the SLTL Group.

By combining hot water production along with electricity generation, the overall efficiency of the system reaches 85%, as compared to 5-6% only for electricity generation alone.

Yes, our product is suitable for different industrial, agricultural and domestic sectors. It includes chemical, pharmaceutical, rubber, paint, alloy, paper industries where availability of waste heat source is there.

In any domestic, hospitality and/or agricultural sector where demand for hot water supply besides power generation is high, this system can be well employed.

On the other hand, SLTL also demonstrates a hybrid closed looped system for space cooling applications by combining solar thermal and biogas energy.

II) Presenting Space Cooling Technology :

This unique technology primarily uses solar energy collected through parabolic trough which heats up room temperature water (~35°C) to hot water in the range of 70-90°C.

These troughs can be placed on the field or as rooftop panels along with the sun tracking unit. The solar radiation is continuously monitored and any degradation in energy gives a signal to the biogas generation plant to operate.

In this portable biogas plant, concentrated radiant energy (such as a laser) is used to produce biogas from agricultural/municipal waste. When there is low solar radiation available(such as in the rainy season or night-time), these biogas burners operate as the primary unit for hot water production in place of the solar trough. The hot water produced by these two means is utilized to evaporate lithium bromide solution in a vapor absorption chiller. Thus, the absorption chiller runs 24×7 without any interruption which subsequently cools down inlet refrigerant water from 15°C to 8°C. This chilled water finally goes to an AHU (Air Handling Unit) for space cooling applications.

The advantage of vapor absorption chiller is that it utilizes thermal energy instead of electric power. Solar energy being abundantly available in a country like India is most suitable for space cooling purposes.

However, though being most clean-tech, solar energy is not well accepted due to the inherent scarcity of its availability during night-time or in the rainy season. This hybrid technology of SLTL has overcome a challenge by adding a secondary unit of in-situ biogas generation plant which makes it suitable for operation at any climatic condition.

SLTL’s space cooling system is based on two renewable energy sources:

i) Solar

ii) Biogas

Solar energy is abundantly available for free. While for biogas, we are utilizing agricultural/municipal waste which is also freely available in rural India. So, in this case, energy-saving should not be the prime focus as we are not using electrical energy for space cooling. Yes, this product can be used in different industrial, agricultural and domestic sectors; especially where adequate solar energy and agricultural/municipal biomass are available. The system can utilize free energy available from sun or waste agricultural produce and efficiently run cold storage units. It is also suitable for medicinal units including hospitals and pharmaceutical storages.